In the Cochabamba region of Bolivia, the owner of a small egg processing factory was facing a practical business problem: the high cost and unstable supply of externally purchased egg trays were restricting its development. His requirements were clear and pragmatic: “It can use local waste paper as raw material and must be easy to operate.” He finally found a solution—the YG-1500-4X1 model egg crate making machine from YG Machinery of China.【WhatsApp/WeChat/Phone】+86 13837122632

Egg Tray Making Machine Parameters

| Model | Capacity/hour | Power/hour | Voltage | Weight |

| YG-1500 – 4X1 | 1500pcs/h | 38kw | 380V50HZ | 3000kg |

| Dimensions (main machine) | Paper consumption/hour | Water consumption/hour | drying | |

| 2800*2200*1900 | 120kg | 240kg | dry naturally | |

In-depth Analysis of Customer Needs

This small egg processing factory in Bolivia was not large in scale, and its needs profoundly reflected the common pain points of local small-scale production enterprises:

- Strong willingness to control costs: The high cost of externally purchased packaging severely eroded profits, and the customer needed to internalize and minimize this part of the expenditure. Therefore, they were extremely sensitive to initial investment and operating costs, and would carefully examine the egg tray machine price and long-term returns.

- Desire to utilize localized raw materials: Local waste paper resources were abundant but underutilized. The customer hoped that the equipment could directly “digest” this waste paper, turning waste into treasure and realizing an internal cycle from raw materials to finished products. This was not only an economic consideration but also in line with the environmental protection trend.

- Hard requirement for operational simplicity: The factory lacked professional equipment engineers, so it needed a piece of equipment with user-friendly design, high automation and simple maintenance, ensuring that ordinary workers could get started and achieve stable output after short-term training.

- Moderate production capacity and flexibility: There was no need for ultra-large industrial production capacity, but stable and reliable output was required to match its own egg processing rhythm, and it should be able to flexibly respond to order fluctuations.

Why Choose YG’s Egg Crate Making Machine Eventually?

After contacting multiple suppliers, why did the customer cast their vote of trust to YG? Our recommendation was based on precise demand matching:

- Precise matching of production capacity and economy: The YG-1500 model had an hourly output of 1,500 pieces, which perfectly met the needs of small and medium-sized processing factories, avoiding investment waste caused by overcapacity. The reasonable egg tray machine price and low energy consumption of 38kw per hour ensured a quick return on investment.

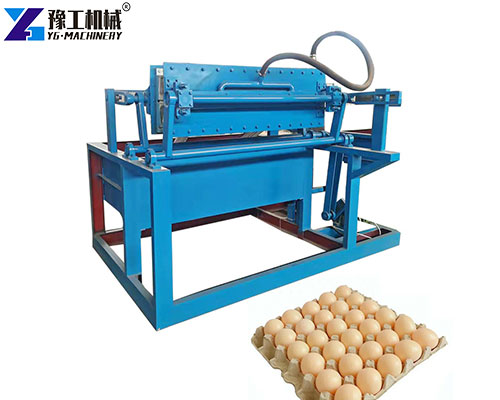

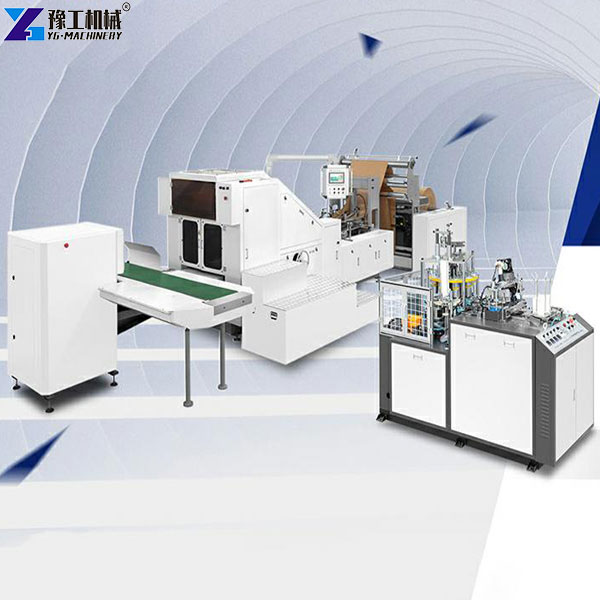

- Mature technology of “turning waste paper into egg trays”: What we provided was a complete egg tray making machine production line, integrating pulping, forming and demoulding in one go. The mature technology was specially optimized for processing mixed waste paper raw materials, making the customer’s idea of “local waste paper raw materials” easy to implement.

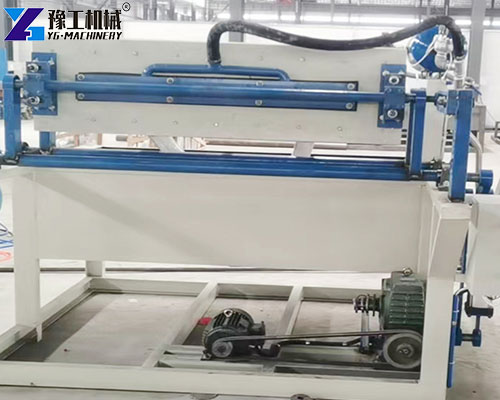

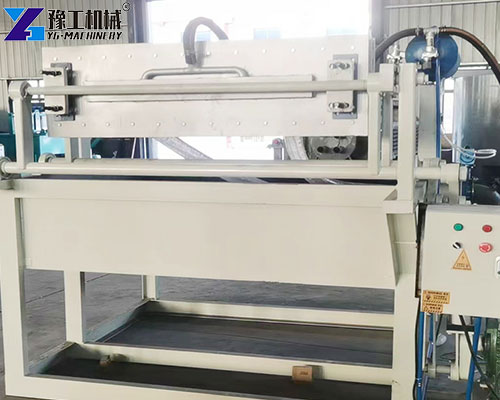

- Design philosophy of “simplicity and reliability”: The whole machine adopted national standard steel and mature and stable worm gear transmission. The core electrical and pneumatic components were all well-known brands, with a low failure rate. This design emphasizing reliability was exactly to meet the core requirements of “easy operation” and “convenient maintenance”, letting customers use it with confidence.

Excellent On-site Performance of YG Egg Crate Making Machine

After the equipment was delivered to Bolivia, installed and put into production, its performance won the customer’s recognition:

- Multi-functionality and efficient forming: This Egg Crate Making Machine adopted a 4X1 design, which could form 4 egg trays per mold. Without increasing additional power and labor, it effectively improved production efficiency and ran smoothly.

- Strong adaptability to raw materials and immediate cost reduction: The supporting pulping and slurry preparation system could well process locally collected waste cartons, newspapers, etc. With only 120kg of paper consumed per hour, the original waste was transformed into protective egg trays, significantly reducing packaging costs.

- Simple operation and easy management: The equipment had a high degree of automation, and the whole process from slurry preparation to suction forming could be controlled through simple settings. The customer reported that after short-term on-site training by our engineers, ordinary workers could independently operate this egg carton machine, greatly reducing the pressure of production management.

Customer Feedback on Egg Carton Machine

“This machine is exactly what we need,” the customer said during a follow-up visit. “Unlike some complex large-scale industrial equipment that is intimidating, it is very practical. It takes in waste paper and spits out usable egg trays. The operators all say it is simple and easy to understand, and production has stabilized in no time. When comparing egg tray making machine before, we valued YG’s practicality and reliability, and now it turns out to be a completely correct choice.” This evaluation is the best interpretation of the value of this Egg Crate Making Machine.

Contact Us to Start Cooperation

Choosing YG means choosing a reliable partner focusing on pulp molding solutions. We are committed to providing you with full-cycle support from consultation to commissioning. And if you’re interested in our egg crate making machine for Bolivia & South America, contact us via the following:

1. Obtain customized solutions and clear quotations

Please inform us of your specific needs, and we will provide you with a tailor-made production line plan and a transparent egg tray machine price analysis.

2. Contact the professional sales team

You can directly contact us through the phone number or email on our official website. We have Spanish/English specialists on hand to answer your inquiries about the performance and logistics of egg carton machine in a timely manner.

3. Book an online live factory tour

Welcome to book a video call to visit our factory and equipment testing in real time, and intuitively understand the operation status of egg tray making machine.

4. Enjoy full-process support services

Specifically,from signing the contract to production, we provide a full set of services including installation, commissioning and operation training to ensure that your egg crate making machine is put into production smoothly and generates stable revenue.

Take action now and let YG help you achieve efficient and environmentally friendly localized production!【WhatsApp/WeChat/Phone】+86 13837122632

No responses yet