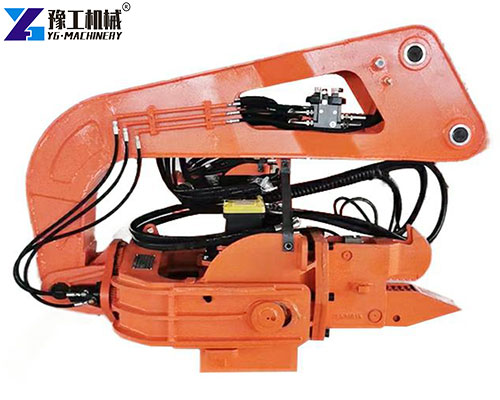

The excavator shear attachment can transform an ordinary excavator into a powerful and multifunctional working platform. This hydraulic tool delivers exceptional cutting force to efficiently handle steel, metal structures, and construction waste, greatly improving work efficiency while reducing labor costs. Choosing the right equipment is crucial for contractors. In addition, YG Machinery also provides other excavator attachments such as milling cutters, hydraulic suction cups, and vibrating screens. Feel free to contact us anytime for a customized quotation! 【WhatsApp/WeChat/Phone】+86 13837122632

YG Excavator Shear Attachment Parameters

The following tables detail the specifications of two types of excavator shear attachment — the Eagle Beak Shear and the Double-Cylinder Hydraulic Shear. These data are based on actual product design to ensure accuracy and reliability.

Eagle beak shear:

| Item | YG-620 | YG-1413 | YG-2200 | YG-2977 | YG-4052 |

| Weight kg | 620 | 1413 | 2200 | 2977 | 4052 |

| Max. Open Size mm | 334.4 | 540 | 500 | 660 | 801 |

| Width mm | 864 | 1175 | 1370 | 1600 | 1700 |

| Height mm | 1521 | 2050 | 2380 | 2600 | 2700 |

| Effective Shear Depth mm | 286 | 348 | 486 | 578 | 736 |

| Rotating Way | 360 collision | 360 hydraulic | 360 hydraulic | 360 hydraulic | 360 hydraulic |

| Working Pressure Bar | 235 | 300 | 320 | 320 | 320 |

| Bottom Shear Force T | 81.2 | 138.2 | 171.2 | 330.2 | 387.2 |

| Medium Shear Force T | 50.2 | 80.2 | 100.2 | 189.2 | 218.2 |

| Tip Shear Force T | 32.2 | 53.2 | 75.2 | 127.2 | 147.2 |

| Applied Excavator Weight T | 5–9 | 10–19 | 20–25 | 28–35 | 38–50 |

Double-Cylinder hydraulic shears for excavator:

| Product Model | Applicable Excavator (T) | Working Pressure (MPa) | Overall Length (mm) | Overall Weight (kg) | Max. Opening (mm) | Blade Length (mm) | Front Crushing Force (KN) | Central Crushing Force (KN) |

| PC-30 | 3 – 4 | 24.5 | 970 | 300 | 360 | 100 | 235 | 410 |

| PC-50 | 4 – 5 | 24.5 | 1180 | 390 | 500 | 110 | 343 | 529 |

| PC-70 | 6 – 8 | 24.5 | 1720 | 740 | 630 | 130 | 431 | 676 |

| PC-150 | 12 – 18 | 31.5 | 2070 | 1440 | 1000 | 170 | 725 | 1120 |

| PC-250 | 20 – 28 | 31.5 | 2400 | 2410 | 1300 | 210 | 1160 | 1730 |

| PC-350 | 30 – 40 | 31.5 | 2780 | 3610 | 1500 | 240 | 1380 | 2110 |

YG Excavator Shear Attachment Advantages

Eagle beak shear

- Excellent Material Durability: Made with Swedish Hardox Hituf steel, offering outstanding toughness and wear resistance to extend lifespan in heavy-duty operations — ideal for large steel cutting.

- High-Strength Core Components: Equipped with 42CrMo alloy pins for superior strength and fatigue resistance. The imported Swiss rotary motor provides high torque and fast rotation for improved efficiency.

- Reliable Hydraulic System: Large cylinders use honed tubes and NOK seals to minimize leakage risk, ensuring short working cycles and long service life — ideal for continuous operations.

- Heat-Resistant Blade Design: The alloy steel blades resist high temperatures and deformation, maintaining sharpness and reducing maintenance costs.

Double-Cylinder hydraulic shears for excavator

- High-Efficiency Performance: Built with wear-resistant steel plates and efficient cylinders, reducing jaw opening/closing time to improve productivity — ideal for rapid demolition tasks.

- Flexible Operation: 360° dual-direction rotation allows operators to cut from multiple angles, adapting to complex environments with high precision.

- Easy Maintenance: Alloy blades enhance cutting capacity and can be replaced easily without welding or grinding, minimizing downtime and long-term costs.

- Wide Compatibility: Models from PC-30 to PC-350 fit excavators from 3 to 40 tons, making it an economical and practical hydraulic shears for excavator option.

Applications of excavator shear for sale

- Building Demolition: In structures such as bridges and buildings, excavator shear for sale efficiently cuts through rebar and steel, improving project speed and safety.

- Scrap Metal Recycling: For vehicle dismantling and industrial waste, hydraulic shears for excavator deliver strong cutting power to handle various metals and increase recycling value.

- Industrial Equipment Dismantling: During factory decommissioning, the excavator hydraulic shear precisely disassembles machinery without damaging reusable components, supporting resource recovery.

- Emergency Rescue Operations: In disaster relief, this attachment quickly removes metal obstacles to open rescue paths, showcasing its multifunctional capabilities.

Buying Guide and Suggestions

- Match Equipment Specifications: Choose models based on excavator weight and pressure — smaller jobs may use YG-620 or PC-30, while heavy-duty work may require YG-4052 or PC-350 for safety and efficiency.

- Assess Job Requirements: For thick steel cutting, the Eagle Beak Shear is ideal; for general demolition, the double-cylinder excavator hydraulic shear offers more flexibility. Many excavator shear for sale models also support customization.

- Consider Maintenance Costs: Check blade replacement cycles and hydraulic system reliability to select an easy-maintenance excavator hydraulic shear, reducing long-term costs.

- Verify Quality Certifications: Ensure products meet CE or ISO standards to guarantee safety and durability while minimizing procurement risks.

Whether it’s the durability of the Eagle Beak Shear or the flexibility of the double-cylinder excavator hydraulic shear, both help users tackle diverse challenges. When selecting an excavator shear attachment, always match your operational needs with technical data and product advantages to make a wise investment. There are many excavator shears for sale options on the market — we recommend working with a professional supplier like YG Machinery for tailored solutions. Contact us anytime for more information!【WhatsApp/WeChat/Phone】+86 13837122632