In order to enhance production efficiency and ensure consistent product quality, an Argentinian precast factory has recently adopted our latest fiberglass spraying machine. This upgrade has delivered remarkable results in terms of production capacity, quality improvement, and cost optimization. The case not only demonstrates the technical advantages of our equipment but also reflects the growing demand for advanced spraying solutions in Argentina’s booming construction sector.【WhatsApp/WeChat/Phone】+86 13837122632

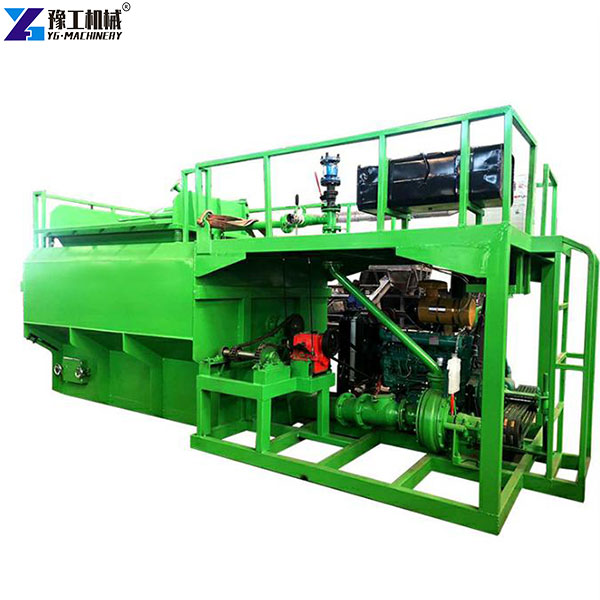

| Product name | Glass Fiber Reinforced Concrete GRC Spray Machine |

| Power | 2.2-4.0kw |

| Voltage | 380v 50hz |

| Speed | 20-200r/min |

| Workspace | 4.5m |

| Delivery capacity | 300-1600kg/h |

| Production efficiency | 200-400m2/h |

| Volume | 60L |

| Dimension for the sprayer | 2000*1050*1600mm |

| Dimension for the mixer | 1550*1000*2100mm |

| Total weight | 800kgs |

Customer Background and Industry Challenges

The customer is a manufacturer specializing in European-style architectural components, exterior wall panels, and artistic sculptures—products widely used in high-end real estate, commercial buildings, and decorative renovation projects.

However, prior to adopting the new equipment, the factory faced several persistent challenges:

Low efficiency with traditional manual spraying – Workers could only cover a limited area each day, making it difficult to meet the deadlines of large-scale projects.

Unstable material ratios – Manual mixing often led to uneven fiber distribution, resulting in inconsistent strength and surface finish.

High labor intensity and production costs – Skilled spraying workers were hard to find, and training new employees required significant time and resources.

With increasing orders and growing competition, the customer urgently needed a high-performance GRC spraying machine capable of increasing production speed, maintaining spraying uniformity, and reducing labor dependency.

Solution – High-Efficiency Fiberglass Spraying Machine

After a detailed production assessment, we recommended our advanced fiberglass spraying machine, designed for precision and high-volume GRC manufacturing. The equipment offers several core advantages:

Stable material feeding – The wear-resistant stainless-steel rotor combined with a PTFE stator screw pump ensures a continuous, smooth flow of materials without significant pulsation, guaranteeing even spraying across all surfaces.

Flexible operation – The 4.5-meter horizontal swing arm and universal workbench provide a wide operational range, reducing downtime caused by frequent equipment repositioning.

Multiple spraying modes – The dual-pipe mixing spray gun supports both fan-shaped and directional spraying patterns, allowing the operator to adapt to different component shapes and project requirements.

Easy maintenance and mobility – The compact structure allows for quick disassembly and transportation, making it ideal for Argentina’s diverse construction site conditions, from urban façades to remote project locations.

Implementation Results of the GRC Spraying Machine

Since the installation of the fiberglass spray machine for sale, the customer has reported significant improvements in multiple aspects:

Efficiency increase – The spraying area has reached 200–400 m² per hour, enabling the factory to handle larger projects with shorter delivery times.

Quality improvement – The fiber distribution is now more uniform, surface flatness has improved, and the defect rate has been reduced by more than 30%.

Cost optimization – Operator training time has been cut to just two days, minimizing labor costs and reducing reliance on experienced sprayers.

Customer Feedback on the GRC Machine

The Argentinian factory expressed high satisfaction with the GRC machine’s performance and stability. During exterior wall panel projects, the spraying speed was fast, the coverage uniform, and the product precision consistently high. These improvements have greatly enhanced project delivery efficiency and strengthened the company’s market competitiveness in Argentina’s construction and decoration industry.

A Reliable Choice for GRC Production

This case study highlights the exceptional advantages of the fiberglass spraying machine in modern GRC manufacturing: rapid operation, stable quality, and strong adaptability. Whether for decorative GRC panels, architectural components, or special coatings such as fireproof, waterproof, and thermal insulation layers, this machine delivers professional-grade results.

For manufacturers in Argentina and beyond seeking to improve production efficiency and product quality, YG Machinery offers reliable, high-performance solutions. In addition to the GRC spraying machine, our product range also includes polyurethane spraying machines, mortar spraying machines, and concrete pumps—meeting diverse needs in the global construction market.【WhatsApp/WeChat/Phone】+86 13837122632

No responses yet