The fully automatic toilet paper production machine is pivotal for boosting efficiency. Its highly integrated design merges rewinding, slitting, and packaging into a seamless automated process, covering everything from base paper input to finished product output. It drastically cuts labor needs, minimizes the impact of fluctuating labor costs, and ensures steady product quality through precise, standardized operations. This creates an efficient, high-quality, and cost-effective production model, helping businesses seize opportunities in fierce markets and secure far greater returns. Contact us to get your exclusive quotation and product manual.【WhatsApp/WeChat/Phone】+86 13837122632

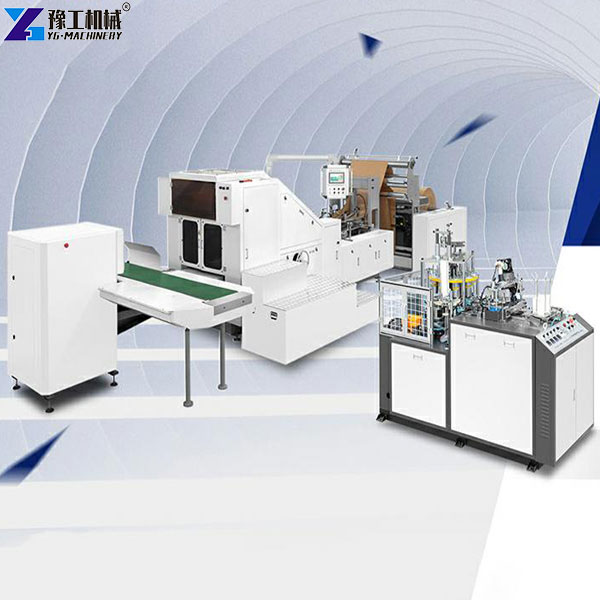

Core Components of The Fully Automatic Toilet Paper Production Machine

1.YG-1880R automatic rewinder

As a key component of the toilet paper production line, the YG-1880R automatic rewinder has powerful functions, with the following parameters:

| Parameter | Detail |

| Finished roll diameter | Φ40-180mm |

| Finished roll core | Φ30-55mm |

| Paper Weight | 13-18gsm single layer |

| Jumbo Roll Width | <2200mm |

| Jumbo Roll Diameter | <Φ1200mm |

| Paper Core Inner Dia. | Φ76.2mm |

| Speed | 150-280m/min |

| Perforation Pitch | 150-300mm |

| Parameter Setting | PLC computer interface |

| Back Stand | 3 layer synchronous transmission |

| Host Power | 380V/50HZ/3PH, 5.5kw |

| Weight | 2800kg |

| Dimensions | 6500x3650x1750mm |

It has functions of connection, roll turning, and automatic tube dropping. It is suitable for base paper within 2.2 meters (1930mm paper is commonly used), with a maximum base paper diameter of 1.3 meters. The output is 2.5 tons in 8 hours, and each roll is about 400kg, providing stable material supply for subsequent links.

2.YG-1880C automatic toilet roll cutting machine

It is the core of the slitting link in the toilet paper production line, with the following parameters:

| Parameter | Detail |

| Cutting speed | 150-180 cuts/min |

| Raw roll length | <2200mm |

| Cutting channel | 1 |

| Cut length | <400mm |

| Cut diameter | 60-130mm |

| Total power | 380V/50HZ/3PH, 6KW |

| Paper cutting accuracy | ±1MM |

| Weight | 1800kg |

| Dimensions | 3850x1100x1850mm |

Controlled by PLC, it can automatically feed paper and perform precise slitting. The long paper rolls produced by the rewinder are transported to this equipment through the connection function, ensuring that the slit paper rolls have uniform specifications and meet various packaging needs.

3.YG-240 automatic packaging machine

As the final link in the toilet paper production line, the YG-240 automatic packaging machine integrates multiple functions, with the following parameters:

| Parameter | Detail |

| Input roll width | 60-160mm |

| Input roll diameter | 80-130mm |

| Packed bag width | <240mm |

| Packed bag length | <600mm |

| Packing Speed | 10 bags/min |

| Total power | 2.2KW |

| Weight | 800kg |

| Dimensions | 5000x1000x1450mm |

The slit paper rolls are transported to this machine via a conveyor belt, which can automatically feed paper, arrange materials, bag, and seal. Only one person is needed to assist with bagging, and the finished products are automatically sent out. It can pack 5-15 packs per minute and can also pack two rows of paper, providing strong support for efficient output.

Operation Process of the Fully Automatic Toilet Paper Production Machine

- The YG-1880R rewinder produces long finished paper rolls, which are transported to the YG-1880C automatic slitting machine through the connection function;

- The automatic slitting machine completes precise slitting according to the set parameters;

- The slit paper rolls are transported to the YG-240 packaging machine via a conveyor belt for automatic material arrangement, bagging, and sealing;

- Only one person is needed to assist with bagging throughout the process to complete the packaging of two rows of paper, greatly simplifying the production process.

3 Advantages of Fully Automatic Toilet Paper Making Machine

- Strong adaptability of equipment performance: The fully automatic toilet paper making machine can flexibly match the parameters of the rewinder, slitting machine, and packaging machine according to production scale, base paper specifications, and finished product requirements. For small production enterprises, they can refer to the small toilet paper machine price to choose suitable configurations. It can operate stably whether for large-scale centralized production or small-batch diversified customization.

- Precise and efficient slitting link: The YG-1880C automatic toilet roll cutting machine has high precision and fast speed, with a cutting speed of 150-180 cuts/min and a paper cutting accuracy controlled within ±1MM. It can precisely cut paper rolls of different specifications to meet various packaging needs.

- Efficient and flexible packaging link: The YG-240 automatic packaging machine has a packaging speed of 10 bags/min and can pack multiple rows. The slit paper rolls are automatically fed, arranged, bagged, and sealed, with only one person needed to assist with bagging, which significantly improves the output rhythm of finished products and meets the efficient shipment needs of enterprises.

Choose High-Quality Equipment

A high-quality fully automatic toilet paper production machine can significantly increase efficiency for enterprises. The full-process automation saves labor and stabilizes quality. The rewinder provides stable material supply, the slitting machine performs precise cutting, and the packaging machine efficiently seals bags, working together to build an efficient production line. If you want to know more details about the equipment, customize an adaptation plan, or consult information about the small toilet paper machine price, please feel free to contact us. We provide professional technical support to help with production upgrading. In addition, YG Machinery also sells high-quality equipment such as paper cup machines, egg tray maker machines, and paper bowl machines. 【WhatsApp/WeChat/Phone】+86 13837122632