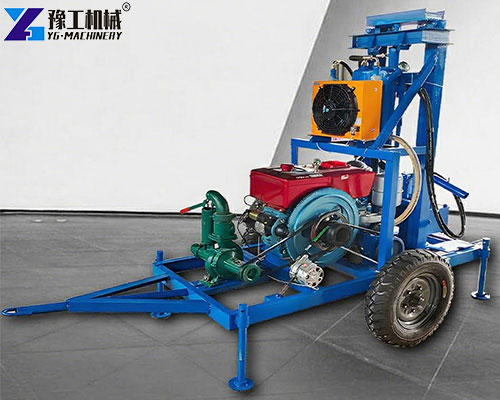

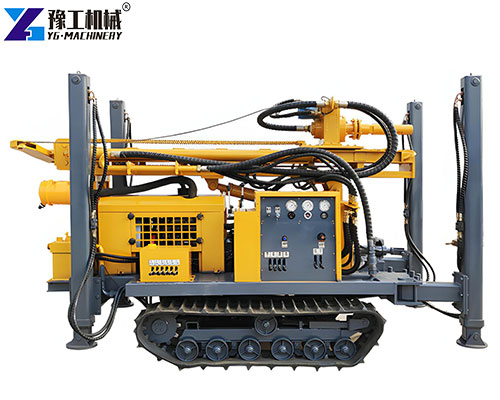

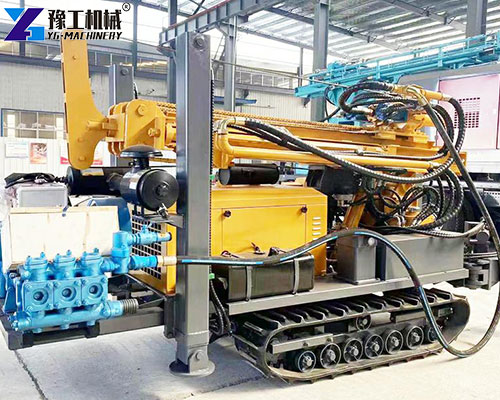

The hydraulic well drilling rig launched by YG Machinery combines advanced hydraulic technology with a solid structure, specially designed for various complex geological formations. This equipment realizes full-process automation such as mast lifting and drill rod handling through the hydraulic system, significantly improving construction efficiency and project quality. Feel free to contact us anytime for more information about water drilling equipment for sale and customized quotations! In addition, YG also provides vertical core drilling rigs, full hydraulic core drilling rigs, and small water well drilling machines for your choice.【WhatsApp/WeChat/Phone】+86 13837122632

Hydraulic Well Drilling Rig Parameters Overview

| Model | YG-180 | YG–200 | YG–300 | YG–300A | YG–400 | YG–600 |

| Drilling hole diameter | 140-254mm | 140-305mm | 140-325mm | 140-325mm | 140-350mm | 140-350mm |

| Drilling depth | 180m | 200m | 300m | 300m | 400m | 600m |

| One-time advance length | 3.4m | 3.4m | 6.6m | 3.4m | 6.6m | 6.6m |

| Walking speed | 2.5km/h | 2.5km/h | 2.5km/h | 2.5km/h | 2.5km/h | 2.5km/h |

| Climbing angles (Max.) | 30 | 30 | 30 | 30 | 30 | 30 |

| Equipped capacitor | 55kw | 65-70kw | 84kw | 75.8kw | 92kw | 115kw |

| Using air pressure | 1.7-2.5mpa | 1.7-3.0mpa | 1.7-3.3mpa | 1.7-3.0mpa | 1.7-3.5mpa | 1.7-3.5mpa |

| Air consumption | 17-31m³/min | 17-30m³/min | 17-35m³/min | 17-35m³/min | 17-35m³/min | 17-35m³/min |

| Drill pipe length | 1.5m, 2.0m, 3.0m | 1.5m, 2.0m, 3.0m | 1.5m, 2.0m, 3.0m,6.0m | 1.5m, 2.0m, 3.0m | 1.5m, 2.0m, 3.0m,6.0m | 1.5m, 2.0m, 3.0m,6.0m |

| Drill pipe diameter | 76mm, 89mm | 76mm, 89mm | 89mm, 102mm | 76mm, 89mm, 102mm | 89mm,102mm,108mm | 102mm,108mm,114mm |

| Rig lifting force | 15t | 12t | 20t | 16t | 22t | 28t |

| Swing speed | 45-65rpm | 45-70rpm | 45–115rpm | 40–70rpm | 45-115rpm | 45–115rpm |

| Swing torque | 3200-4600(N.m) | 3500-4800(N.m) | 6200-8500(N.m) | 5700-7500(N.m) | 6500-9000(N.m) | 8500-11000(N.m) |

| Dimension | 3800*1500*2200mm | 4000*1750*2450mm | 5900*2000*2850mm | 4100*1950*2600mm | 5900*2100*2850mm | 6000*2200*2850mm |

| Weight | 4500kg | 5800kg | 9000kg | 7000kg | 10000kg | 12000kg |

4 Advantages Of Hydraulic Well Drilling Rig

- Full hydraulic automated operation: All key functions, such as mast lifting, drill rod handling, and movement, are controlled by the hydraulic system. This not only reduces labor intensity but also improves precision, making the hydraulic water well drilling rig a synonym for efficient construction.

- High-performance impact and slag removal system: Using an air compressor to support hammer operations, the rig can quickly crush rocks and clear debris. The unique air-sealed structure and oil atomizer design extend component lifespan and ensure reliable continuous operation.

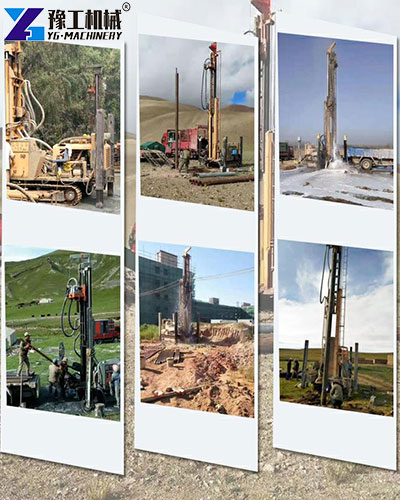

- Flexible mobility and stable positioning: The crawler chassis supports a 2.5km/h walking speed and 30-degree climbing ability, combined with four hydraulic jacks for quick leveling. This design enables stable operation both in mountainous areas and on city roads, optimizing the adaptability of water drilling equipment for sale.

- Smart control and protection: The rotation system uses American technology motors with adjustable torque. The pre-filter removes 90% of dust, while the compensating slider protects drill rods. These features significantly improve equipment durability and safety.

Daily Maintenance Tips

- Lubrication system check: Before each shift, grease the hoist, and when refueling, open the nozzle at the other end to discharge old grease to avoid seal damage. Regularly check oil tanks and prevent mud contamination from wearing down bearings.

- Inspection of key components: Check the main and auxiliary wire ropes for broken strands and connection reliability; inspect the steel structure for rust, cracks, or welding defects. Address any hazards promptly to keep the hydraulic water well drilling rig in optimal condition.

- Hydraulic and pneumatic system maintenance: Monitor the hydraulic oil cooler to ensure continuous operation under high temperatures; clean the air pre-filter to reduce engine wear. These practices directly affect the long-term operating cost of well drilling rig price.

Comparative Analysis: Full Hydraulic vs. Mechanical Drilling Rigs

- Operation efficiency comparison: Hydraulic systems achieve stepless speed regulation and precise control, while mechanical rigs rely on gearboxes, making operation cumbersome. YG’s hydraulic well drilling rig improves work efficiency by over 30%, shortening project cycles significantly.

- Adaptability differences: Hydraulic rigs automatically adapt to geological changes through pressure compensation, while mechanical rigs require manual adjustment. This intelligent feature allows the hydraulic well drilling rig to perform more stably in complex formations.

- Maintenance cost analysis: Hydraulic rigs feature modular design, making fault diagnosis and part replacement easier; mechanical rigs are complex, with higher maintenance time and costs. From the long-term perspective of well drilling rig price, hydraulic models are more cost-effective.

- Technical scalability: Modern hydraulic well drilling rig can easily integrate automation and remote monitoring, leaving room for future upgrades, while mechanical rigs have limited retrofit options.

Choose YG Machinery

YG Machinery’s hydraulic water well drilling rig series combines innovative hydraulic engineering with user-friendly design, suitable for challenging environments worldwide. Whether for agricultural irrigation or industrial water extraction, our products deliver outstanding performance. Contact our team today for detailed quotations and customized services—let YG professional equipment be the strong foundation for your project’s success! 【WhatsApp/WeChat/Phone】+86 13837122632