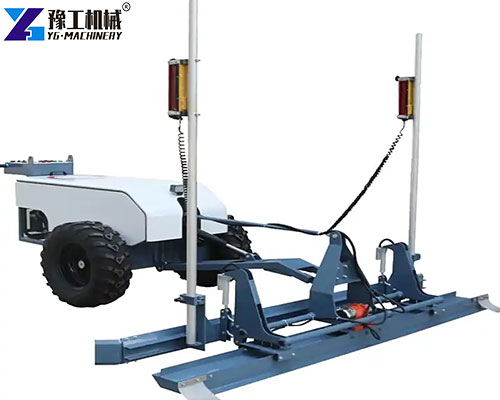

With the growing demand in the American construction market for high-efficiency and low-rework concrete projects, contractors are increasingly focusing on construction speed and precision. To meet this trend, YG Machinery has recently successfully exported a batch of high-performance laser concrete leveling machine to the U.S. market. This equipment not only significantly improves construction efficiency but also reduces material waste and labor costs, making it an ideal choice for modern concrete projects. In addition, YG Machinery also offers concrete pumps, rollers, mixers, and other equipment. Feel free to contact us for a free quote!【WhatsApp/WeChat/Phone】+86 13837122632

Laser Concrete Leveling Machine Specifications

| Model | YGJX31 | YGJX32 | YGJX33 | YGJX34 |

| Engine | ||||

| Model | Generator set | GX390 Electric start | GX390 Electric start | GX390 Electric start |

| Power | 2.0kW | 13hp/3600rpm | 13hp/3600rpm | 13hp/3600rpm |

| Fuel tank (L) | 14.5 | 6.5 | 6.5 | 6.5 |

| Running device | ||||

| Drive | Motor | Hydraulic motor | Hydraulic motor | Hydraulic motor |

| Running mode | Infinitely variable speed | Handle control, stepless speed | Handle control, stepless speed | Handle control, stepless speed |

| Running speed(m/min) | 0-36 | 0-45 | 0-65 | 0-45 |

| Suggest working speed(m/min) | 5 | 5 | 5 | 5 |

| Screed head | ||||

| Type | Self-leveling | Electric control, self-leveling | Self-leveling | Hydraulic control, self-leveling |

| Width | 2500mm | 2500mm | 2500mm | 2500mm |

| Exciting force | 500N | 500N | 500N | 500N |

| Vibration frequency | 50Hz | 50Hz | 50Hz | 50Hz |

| Laser control system | ||||

| Control type | Microcomputer laser scan | Microcomputer laser scan | Microcomputer laser scan | Microcomputer control |

| Operation mode | Walk-behind | Walk-behind | Walk-behind | Walk-behind |

| Forward and reverse | Handgrip control, stepless speed-walking | Hydraulic control | Handgrip control, stepless speed-walking | Hydraulic control |

| Size and weight | ||||

| Working size(mm) | 2758*2622*1980 | 2740×2659×1980 | 2578×2643×1980 | 2780*2622*1980 |

| Weight(kg) | 295 | 365 | 380 | 410 |

Features of the Laser Concrete Leveling Machine

- Powerful Engine and Motor: High-performance engine and hydraulic drive ensure the concrete laser leveling machine runs steadily over large construction areas, improving overall efficiency.

- Precision Screed Head: Self-leveling or hydraulic control screed head maintains floor flatness, reduces rework, and lowers construction costs.

- Fast Construction: Maximum walking speed up to 65 m/min, with microcomputer laser control ensuring both precision and efficiency.

- Comfortable Operation: Walk-behind ergonomic design prevents operator fatigue during long work hours, improving productivity.

- Durable and Reliable: Reinforced frame and vibration system adapt to various construction environments, ensuring long-term stability and durability.

Common Construction Challenges and Solutions

Even experienced contractors may encounter challenges during actual construction:

- Uneven Floor Surfaces: Traditional manual or low-precision equipment often causes uneven concrete floors, increasing rework and material waste.

- Solution: Our laser concrete leveling machine is equipped with a precision self-leveling or hydraulic control screed head combined with a microcomputer laser scanning system to adjust height in real-time, ensuring each square meter is perfectly flat.

- Low Construction Efficiency: Large-scale pouring consumes significant time and labor, potentially delaying project progress.

- Solution: The equipment supports up to 65 m/min walking speed and can be operated via walk-behind or hydraulic control, significantly improving efficiency and reducing labor input.

- Difficult Operation: Some equipment is bulky or heavy, causing fatigue during long hours and affecting construction quality.

- Solution: The laser concrete leveling machine features ergonomic walk-behind design, optimized vibration and noise, maintaining precision even during extended work sessions.

- Environmental Factors Affecting Construction: Humidity, temperature changes, or complex terrain may make concrete leveling difficult.

- Solution: The powerful engine and hydraulic system provide stable output, while the self-leveling screed head handles complex conditions, keeping floor flatness unaffected by external factors.

Customer Usage Scenarios

- Commercial or industrial contractors can quickly complete large-scale floor leveling in warehouses, factories, or shops, saving labor and time costs.

- Residential construction companies can achieve precise leveling for yards, driveways, and basements, ensuring flatness and aesthetic quality, increasing client satisfaction.

- Even in complex or continuous pouring site conditions, this concrete laser leveling machine maintains high efficiency, delivering fast and high-precision floor leveling.

Why Choose YG’s Laser Concrete Screed Machine

- Rich Manufacturing Experience: Years of focus on laser screed machine development and production, fully understanding construction demands and industry standards.

- Transparent Pricing: Detailed quotations provided with no hidden fees, ensuring stress-free purchasing.

- Worry-Free After-Sales Service: Technical guidance, spare parts support, and remote assistance ensure long-term stable operation.

Investing in a high-quality laser concrete screed machine is the best choice for modern concrete projects to improve efficiency and reduce costs. With reliable performance, powerful engines, precise laser control, and comfortable operation, this equipment helps contractors efficiently complete each job and achieve perfectly leveled floors. Whether for commercial projects or residential construction, YG’s laser concrete screed machine is an ideal solution. Contact YG Machinery for laser screed price quotes and customized solutions!【WhatsApp/WeChat/Phone】+86 13837122632

No responses yet