A Paraguayan company specializing in mining and road construction needed to upgrade its equipment due to insufficient breaking capacity of its existing machines. After multiple rounds of evaluation and testing, the company finally decided to purchase a rock breaker hammer from YG Machinery.【WhatsApp/WeChat/Phone】+86 13837122632

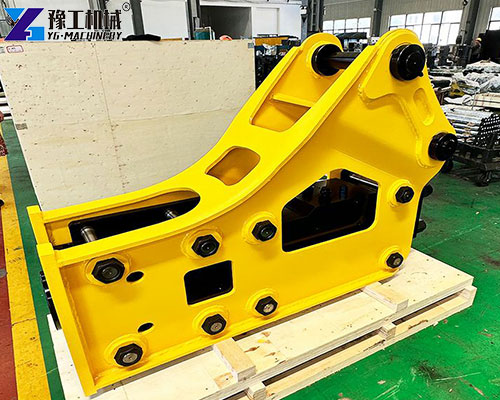

Rock Breaker Hammer Parameters

| Model | Chisel Diameter | Suitable Carrier Weight | Main body Weight | Operating Pressure | Hydraulic Oil Flow | Blow Frequency | Hose Diameter |

| mm | Ton | kg | Kg/cm 2 | I/min | bpm | inch | |

| YG350 | 35 | 0.5-1 | 40 | 90-120 | 15-25 | 800-1300 | 1/2 |

| YG400 | 40 | 1-3 | 53 | 90-120 | 15-25 | 800-1300 | 1/2 |

| YG450 | 45 | 1.2-3.0 | 67 | 90-120 | 20-30 | 700-1200 | 1/2 |

| YG530 | 53 | 2.5-4.5 | 85 | 90-120 | 25-50 | 600-1100 | 1/2 |

| YG600 | 60 | 2-5 | 140 | 90-120 | 25-50 | 600-1100 | 1/2 |

| YG680 | 68 | 4-7 | 152 | 110-140 | 40-70 | 500-900 | 1/2 |

| YG750 | 75 | 6-9 | 210 | 120-150 | 50-90 | 400-800 | 1/2 |

| YG850 | 85 | 7-14 | 278 | 130-160 | 60-100 | 400-800 | 3/4 |

| YG100 | 100 | 10-15 | 475 | 150-170 | 80-110 | 350-700 | 3/4 |

| YG1250 | 125 | 15-18 | 616 | 150-170 | 80-110 | 350-700 | 3/4 |

| YG1350 | 135 | 16-26 | 846 | 160-180 | 130-150 | 400-800 | 1 |

| YG1400 | 140 | 18-26 | 916 | 160-180 | 120-180 | 350-500 | 1 |

| YG1400A | 140 | 18-26 | 952 | 160-180 | 120-180 | 350-500 | 1 |

| YG1500 | 150 | 27-35 | 1088 | 160-180 | 150-190 | 350-700 | 1 |

| YG1550 | 155 | 28-36 | 1309 | 180-200 | 200-260 | 250-400 | 1-1/4 |

| YG1650 | 165 | 30-40 | 1438 | 180-200 | 200-260 | 250-400 | 1-1/4 |

| YG1650P | 165 | 30-40 | 1586 | 180-200 | 200-260 | 250-380 | 1-1/4 |

| YG1750 | 175 | 35-40 | 1929 | 180-200 | 210-290 | 200-350 | 1-1/4 |

| YG1850 | 185 | 35-45 | 2411 | 190-220 | 220-270 | 200-250 | 1-1/4 |

| YG1990 | 190 | 40-55 | 2626 | 190-220 | 220-290 | 180-200 | 1-1/4 |

| YG2100 | 210 | 60-80 | 3396 | 200-240 | 290-350 | 150-200 | 1-1/4 |

Paraguayan Customer Requirements

- Efficiency Needs:

In the company’s mining project, the rocks to be broken have very high hardness. The existing equipment could only break less than 200 cubic meters per day, which could not meet the project schedule. The company urgently needed to improve breaking efficiency. - Compatibility Needs:

Most of the company’s excavators weigh between 15–25 tons, so they needed a rock breaker attachment that was highly compatible and easy to install to avoid extra modification costs. - Durability Needs:

Given the harsh working environment with high temperatures and dust, the equipment needed to operate long hours without failure. This put high demands on the wear resistance and overall stability of the rock breaker hammer

How YG Rock Breaker Hammer Meets Customer Needs

- Efficiency Match:

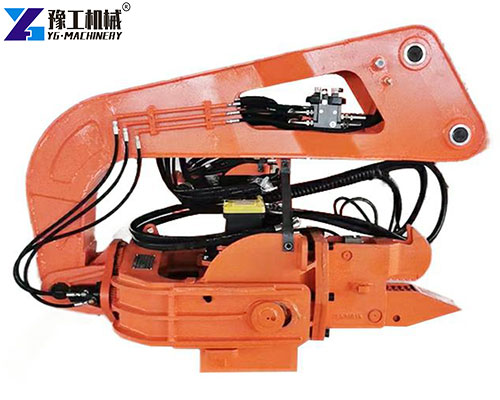

The YG rock breaker attachment adopts an optimized design with extended piston and cylinder stroke, and the piston diameter matches that of the chisel to maximize output energy utilization. For the customer’s 15–25 ton excavators, the recommended YG1350 model delivers a striking frequency of 400–800 bpm, increasing daily output to over 500 cubic meters—perfectly meeting efficiency goals. - Compatibility Match:

The provided excavator breaker attachment features a universal mounting interface that requires no major modifications to the customer’s existing excavators. Installation and commissioning can be completed within one hour, significantly reducing both time and cost. - Durability Match:

Key components such as the piston and main body bolts undergo strict quality inspection and are made of high-strength, wear-resistant materials. Together with a stable oil circuit switching system, the equipment can operate continuously for more than 12 hours in high-temperature and dusty conditions, with a failure rate lower than the industry average.

Application Scenarios and Customer Feedback

- Application Scenarios:

The rock breaker hammer is mainly used in rock breaking for mining operations and road foundation excavation. It can efficiently break granite with a hardness level of up to 8 in mining sites and accurately crush concrete blocks during roadwork without damaging surrounding soil structures. - Customer Feedback:

After one month of use, the customer reported that daily working hours increased by 3 hours and breaking efficiency improved by 150% compared to their previous equipment. No component failures occurred. In addition, the hammer’s low recoil reduced stress on the excavator arm, extending its service life and cutting overall operating costs by around 20%.

Why the Customer Chose YG Rock Breaker Hammer

- 25 Years of Expertise:

As a professional machinery manufacturer, YG Machinery has mature core technology for rock breaker attachment and can offer customized solutions based on specific client needs. - Standardized Production Assurance:

With standardized production workshops, every rock breaker for sale undergoes strict quality control from raw material procurement to final assembly, ensuring consistent performance and reliable quality. - International Certification and Eco-Friendliness:

All products have passed international quality system certification and meet Paraguay’s environmental protection standards. Noise levels are 10 decibels lower than the industry average, minimizing environmental impact and complying with local regulations. - Advanced Production and Inspection Equipment:

Equipped with complete production lines and advanced testing instruments, YG Machinery conducts precise inspections on key performance aspects such as impact force and sealing of each excavator breaker attachment, ensuring a 100% qualification rate before delivery.

The successful delivery of YG’s excavator breaker attachment to Paraguay not only solved the customer’s construction challenges but also expanded YG Machinery’s influence in the South American market. Moving forward, YG will continue to focus on providing high-quality rock breaker for sale solutions, enhancing product performance and service to deliver more efficient and reliable excavator attachments for global construction projects.【WhatsApp/WeChat/Phone】+86 13837122632

No responses yet