In France, a customer faced the dual challenges of reservoir silt accumulation reducing water storage capacity and industrial tank fouling affecting production efficiency. After extensive research, they finally decided to purchase YG Machinery’s sludge cleaning robot. With its targeted dredging solutions, the equipment successfully solved both the reservoir and industrial tank cleaning problems. Feel free to contact us anytime for more product information and exclusive discounts!【WhatsApp/WeChat/Phone】+86 13837122632

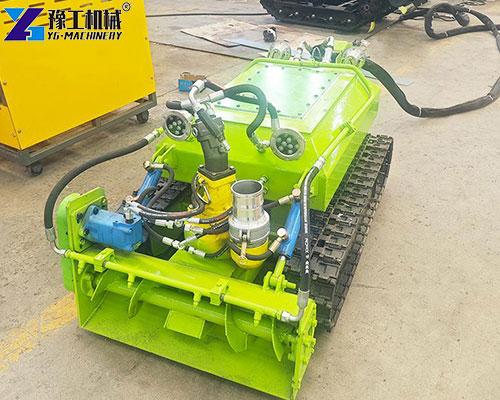

Hot-Selling Model 900 Sludge Cleaning Robot Parameters

| Equipment Name | Specifications / Functions |

| Robot Body | Size: 1750mm×900mm×750mm; Cleaning width: 900mm; Traveling speed: 3-17M/min |

| 4-Inch Underwater Slurry Pump | Used for pumping sludge underwater; Pumping particle diameter: 40mm (replaceable as needed); Head: 40m; Horizontal conveying distance: 100–150m |

| Underwater Hydraulic Power Source | Waterproof hydraulic system |

| Robot Main Control Cabin (Underwater) | Controls all robot actions, including starting/stopping hydraulics and lighting system |

| Underwater Lighting System | 2 LED lights |

| Underwater Camera System | Equipped with 1 underwater camera |

| Cable Reel System | Electric (or manual) drive, speed 0–10r/min |

| Underwater Pipeline | 50m |

| Ground Electrical Control System | |

| Main Electrical Cabinet | Supplies power to all ground systems |

| Main Console | Ground-based main control system for operating the underwater robot |

| Motor | 37 (30) KW |

| Accessories | Sewage pipe, pressure-resistant 20kg, built-in steel reinforcement, length 50m |

| Working Efficiency | 200 m³/hour |

| Water Pump | Motor 3KW |

Sludge Cleaning Robot Meets French Client’S Cleaning Needs

- High Efficiency: YG Machinery’s sludge cleaning robot has a processing capacity of 200 cubic meters per hour. For the reservoir project, it completed the removal of about 5,000 cubic meters of silt within just 15 days, which is 8 times more efficient than traditional manual cleaning. In industrial tank cleaning, it can complete the removal of dirt from two large tanks in a single day, greatly reducing downtime for the customer.

- Safe and Reliable: This dredging robot supports remote control. Since the industrial tanks contained residual chemicals, manual cleaning posed poisoning risks. With this equipment, operators no longer need to approach the tanks—they can complete the cleaning via a ground control console, completely eliminating safety hazards.

- Flexible Adaptability: This dredging robot can adjust dredging modes depending on the environment. In complex underwater reservoir terrain, it flexibly avoids rocks and obstacles; in industrial tanks with narrow inlets and outlets, its compact design allows easy access for full-scale cleaning.

Underwater Robotic Dredge Options to Fit Different Work Environments

The French client chose YG Machinery’s electric underwater robotic dredge based on the operating conditions of both the reservoir and industrial tanks. In the factory area, where power supply is stable, the electric model ensures low noise without affecting nearby workshops. Around the reservoir, temporary power setups also supported continuous operation. Moreover, with its zero-emission feature, the electric version complies with French environmental regulations and prevents secondary pollution of reservoir water.

Client Feedback and Future Cooperation

- User Feedback: The customer reported that the industrial tank cleaning robot is easy to operate, with low failure rates during operation. After-sales service was prompt and effective in problem-solving.

- Cooperation Plan: The client plans to introduce YG Machinery’s dredging robot into future river cleaning projects and for maintaining other factory tanks.

Why Choose YG Machinery

With superior manufacturing processes and strict quality control, YG Machinery’s sludge cleaning robot is not only stable and reliable in performance but also well-received in the global market. The company provides comprehensive after-sales services, including remote technical support, spare parts supply, and maintenance guidance, ensuring efficient operation throughout the equipment’s lifecycle. Contact us anytime for a free quotation!【WhatsApp/WeChat/Phone】+86 13837122632

No responses yet