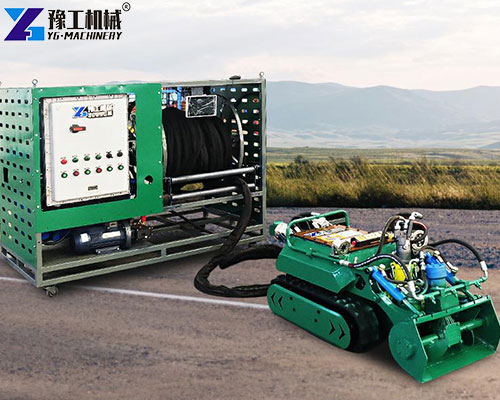

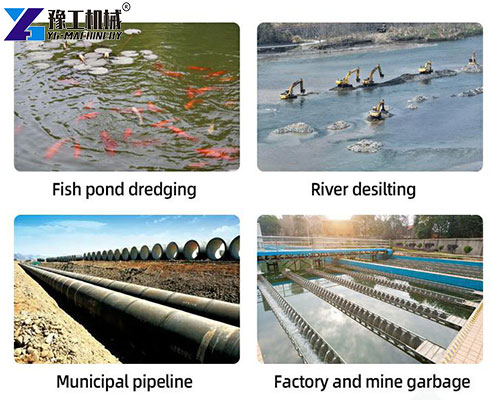

The tank cleaning robot integrates intelligent control, underwater operation, and efficient sludge removal capacity, completely transforming the traditional model of manual work. This type of robot not only improves operational safety but also demonstrates excellent application value in municipal, water conservancy, and industrial fields. In addition, YG Machinery also offers dry ice blasting machines, sandblasters, and other equipment. Feel free to contact us anytime for an exclusive quotation!【WhatsApp/WeChat/Phone】+86 13837122632

Hot-Selling 900 Type Tank Cleaning Robot Parameters

| Equipment Name | Specifications / Functions |

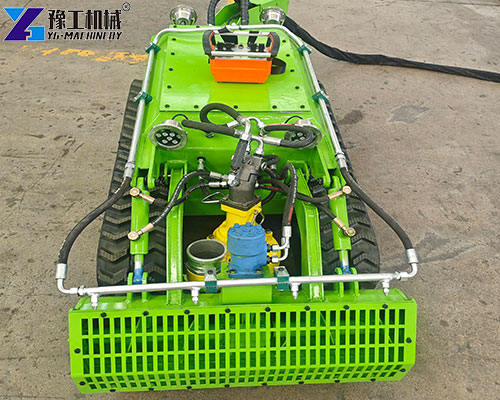

| Robot Body | Size: 1750mm×900mm×750mm; Cleaning width: 900mm; Traveling speed: 3-17M/min |

| 4-Inch Underwater Slurry Pump | Used for pumping sludge underwater; Pumping particle diameter: 40mm (replaceable as needed); Head: 40m; Horizontal conveying distance: 100–150m |

| Underwater Hydraulic Power Source | Waterproof hydraulic system |

| Robot Main Control Cabin (Underwater) | Controls all robot actions, including starting/stopping hydraulics and lighting system |

| Underwater Lighting System | 2 LED lights |

| Underwater Camera System | Equipped with 1 underwater camera |

| Cable Reel System | Electric (or manual) drive, speed 0–10r/min |

| Underwater Pipeline | 50m |

| Ground Electrical Control System | |

| Main Electrical Cabinet | Supplies power to all ground systems |

| Main Console | Ground-based main control system for operating the underwater robot |

| Motor | 37 (30) KW |

| Accessories | Sewage pipe, pressure-resistant 20kg, built-in steel reinforcement, length 50m |

| Working Efficiency | 200 m³/hour |

| Water Pump | Motor 3KW |

3 Advantages of Tank Cleaning Robot

- Efficient Sludge Removal and Powerful Pumping Ability: With a remarkable capacity of 200 m³ per hour, the tank cleaning robot relies on its 4-inch high-power slurry pump. This pump handles particles up to 40mm in diameter and achieves a 40m lift, enabling rapid underwater sludge suction and long-distance delivery. These technical features directly translate into real-world high efficiency.

- Safe and Reliable with Intelligent Control System: Through the cooperation of the underwater control cabin, camera system, and ground console, this water tank cleaning robot achieves full remote and precise operation. Operators can complete cleaning tasks via real-time video monitoring without entering dangerous environments, ensuring safety while replacing hazardous manual work.

- Flexible Adaptation and Durable Design: With compact dimensions of 1750mm×900mm×750mm and a variable speed of 3–17M/min, the robot adapts flexibly to pipelines, tanks, and confined spaces. The waterproof hydraulic system and reinforced materials make this robotic tank cleaning equipment capable of long-term stable performance in harsh underwater conditions, combining flexibility, adaptability, and durability.

Practical Solutions of Tank Cleaning Robot

- Solution: Corrosion Resistance and Precision Cleaning in Industrial Environments

Case: In a Canadian nickel processing plant, the sedimentation tank contained corrosive mineral particles. A corrosion-resistant water tank cleaning robot successfully completed the cleaning task. Its robust structure and precise control avoided equipment damage while recovering valuable metal residues, achieving both environmental and economic benefits. - Solution: Hygiene Cleaning in Agriculture and Food Processing

Case: In Bordeaux, France, a medium-sized winery introduced robotic tank cleaning equipment for cleaning fermentation tanks and sedimentation basins. The robot thoroughly removed tartar deposits, halved cleaning time, and significantly reduced water and chemical usage, meeting strict local food safety standards. - Solution: Sludge Treatment for Large-Scale and Complex Environments

Case: In an agricultural area of Australia, algae outbreaks and sediment accumulation worsened reservoir water quality. A high-power sludge cleaning machine was deployed. Its strong pumping system efficiently processed viscous sludge rich in organics and transported it via long pipelines to designated treatment points. This supported ecological restoration while showcasing strong adaptability to complex sludge compositions.

How to Select Efficient Robotic Tank Cleaning Equipment

- Identify Operational Needs and Scenarios: Before choosing robotic tank cleaning equipment, consider site dimensions, sludge characteristics (viscosity, particle size), and required conveying distances to ensure the right model matches the conditions.

- Compare Core Performance Parameters: Focus on working efficiency (m³/h), pumping power, and control methods (fully remote or wired). For long-distance horizontal transport, select models with higher head capacity like this one.

- Consider Power Source and After-Sales Service: Depending on power availability, choose between electric or diesel versions. Technical support, spare parts supply, and maintenance services from the supplier are also key to long-term stability.

Choose YG Machinery

The YG sludge cleaning machine integrates advanced technology with practical requirements, providing safe, efficient, and eco-friendly solutions for the sludge cleaning industry. With continuous innovation, this devices will play an increasingly vital role across municipal, industrial, and environmental fields. Contact us anytime for exclusive discounts!【WhatsApp/WeChat/Phone】+86 13837122632