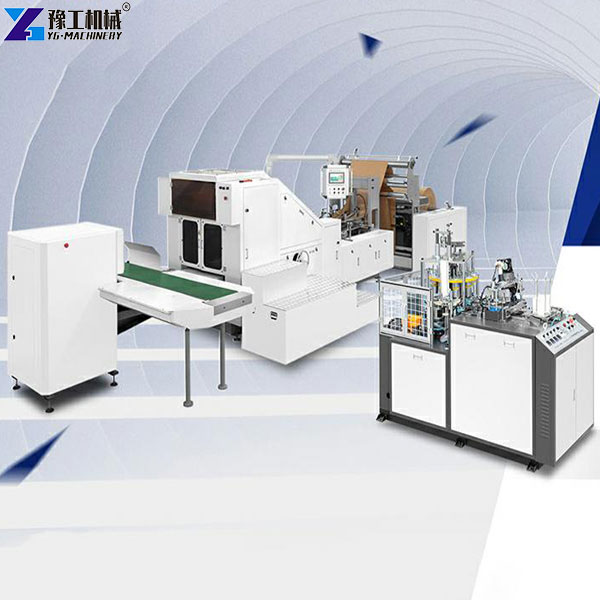

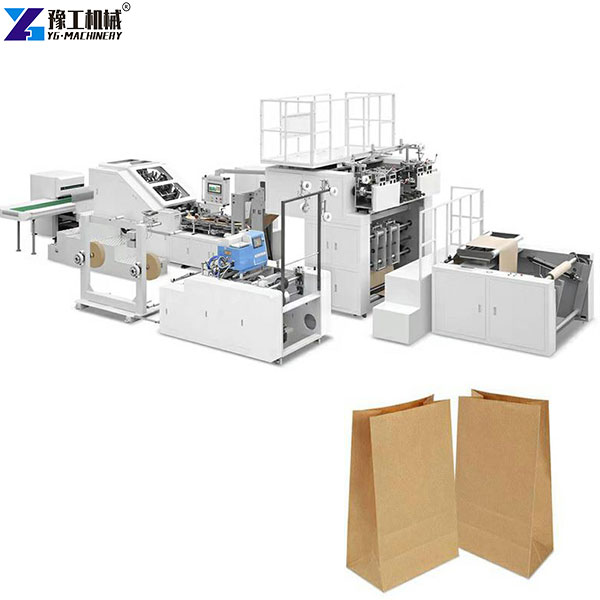

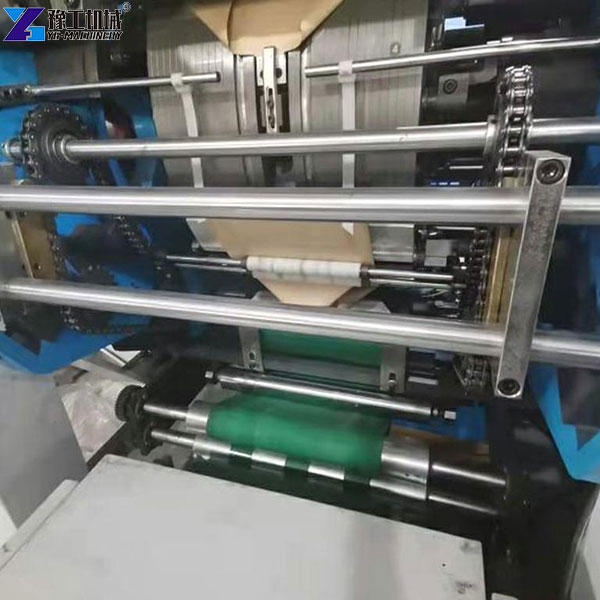

An automatic paper bag making machine is a powerful device for producing hand-carried paper bags with handles. It is especially suitable for mass-producing shopping bags in industries such as food and clothing. First, the handle-making machine forms handles from rope rolls and paper sheet rolls. Then, the conveying system sends the handles to the handle-attaching unit. It pre-breaks the paper rope positions, applies glue to the patch positions, and automatically attaches the handles on the primary color or printed roll paper. After that, the main machine completes subsequent processes such as edge gluing, tube forming, and cutting. The whole process is completed synchronously at one time. Want to know more? We are online 24 hours a day. Contact us to get a preferential quote!【WhatsApp/WeChat/Phone】+86 13837122632

Product Parameters of Automatic Paper Bag Making Machine

The following are the key technical parameters of the equipment to help accurately match production needs:

| Model | YG-FD450T |

| Cutting Length | 270-530mm |

| Cutting Length(total) | 270-430mm |

| Paper Bag Width | 220-450mm |

| Paper Bag Width(total) | 240-450mm |

| Bottom Width | 90-180mm |

| Paper gsm | 80-150g/㎡ |

| Paper gsm(total) | 80-150g/㎡ |

| Material Width | 650-1290mm |

| Material Width(total) | 650-1290mm |

| Paper Material Diameter | 1200mm |

| Paper Core Inner Diameter | 76mm |

| Handle Patch Length | 190mm |

| Handle Patch Width | 50mm |

| Paper Rope Spacing | 95mm |

| Paper Handle Rope Diameter | 3-5mm |

| Handle Patch Paper Roll Width | 100mm |

| Handle Paper Roll Diameter | 1200mm |

| Handle Patch Paper Weight | 100-135g/㎡ |

| Mechanical Speed | 30-180pcs/min |

| Paper Bag Production Speed | 30-150pcsmin |

| Handle Speed | 30-130pcs/min |

| Cutter Method | Pinking |

| Total Power | 380V/ 3Phase 4Line 41.5kw |

| Total Weight | 15500Kg |

| Machine Overall Dimension | 14000*6000*2400mm |

Product Features of Automatic Paper Bag Making Machine

- Smart Interaction: Adopts a Weinview touch-screen human-machine interface. The operation functions are intuitively displayed. The production parameters and operation status are clear at a glance, making it easy to quickly control the equipment. Even beginners can easily get started.

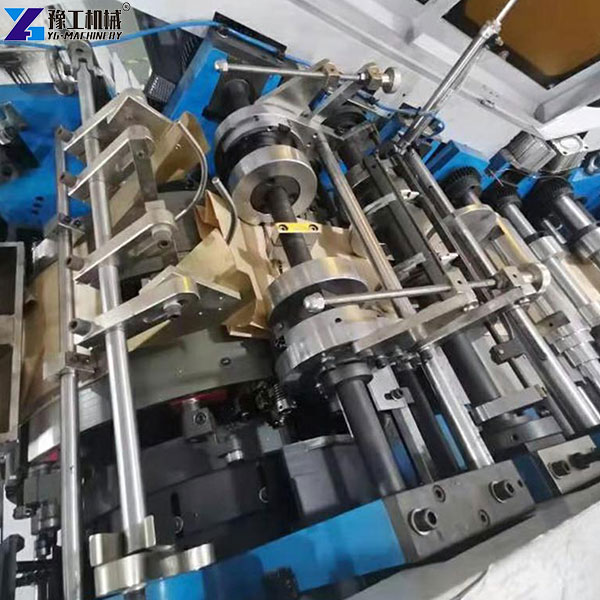

- Stable Drive: Equipped with an original Mitsubishi motion controller from Japan. With the integrated design of optical fiber, the data transmission is efficient, ensuring accurate and stable actions when the equipment runs at high speed and reducing production fluctuations.

- Precise Positioning: The Japanese Mitsubishi servo motor is matched with the German Sick color mark electric eye. It tracks the size of the printed bag in real-time and automatically corrects deviations, ensuring that the printed patterns on the paper bags and the pasting positions of the handles fit precisely.

- Convenient Loading and Unloading: The material loading and unloading is equipped with a hydraulic lifting structure. Workers can easily load and unload paper rolls. The unwinding process adopts full-automatic constant tension control to maintain stable paper conveying and avoid wrinkles and breaks.

- Efficient Deviation Correction: The material deviation correction uses a brushless servo motor, which has a fast response speed. It greatly shortens the paper roll alignment adjustment time, improves the efficiency of order change and material change, and ensures production continuity.

Product Use of Paper Carry Bag Making Machine

The hand-carried square-bottom paper bags produced by this equipment use environmentally friendly paper (supporting biodegradable materials), which conforms to the current green packaging trend and helps enterprises practice the concept of environmental protection. The produced paper bags have a simple and elegant appearance, clear printing, good stiffness, and firm handles. They are suitable for scenarios such as food retail (bread bags, snack bags), clothing shopping (brand clothing bags), and gift packaging. Compared with the traditional square bottom paper bag making machine, it can complete the production and pasting of handles in one piece, and the produced paper bags are more practical and portable.

YG’s Automatic Paper Bag Making Machine, a Reliable Choice

YG Company deeply understands the packaging pain points in industries such as food and clothing. The equipment is optimized and designed for industry needs, with strong adaptability. Our fully automatic paper bag making machine price is in line with the market. The comprehensive performance and cost-effectiveness are outstanding. The cooperative customers report that both the production efficiency and product quality have been improved. Whether you are purchasing a series of square bottom paper bag making machine equipment, or consulting about the fully automatic paper bag making machine price and customizing solutions, we can respond quickly and provide professional answers. Choose YG to make the production of hand-carried square-bottom paper bags more efficient and worry-free. In addition, YG also sells semi-automatic square bottom paper bag machines, paper cup machines, paper bowl machines, toilet paper machines, and other equipment. Welcome to contact us at any time!【WhatsApp/WeChat/Phone】+86 13837122632