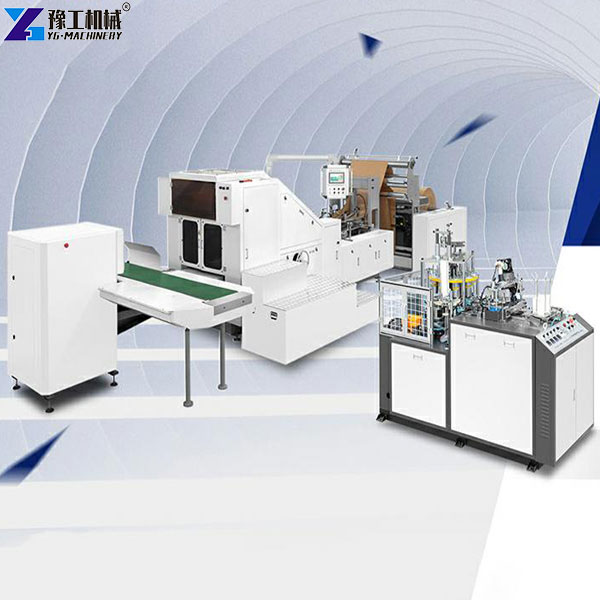

In the disposable tableware production field, the automatic paper plate machine stands out with its intelligent production capacity, becoming the core equipment for mass-producing paper plates. It can quickly process various paper plates, suitable for catering, parties, and other scenarios, saving enterprises a lot of labor costs. Want to know how this equipment boosts production efficiency? To help you get info timely, we’re online 24/7. We’ll provide product manuals and quote discounts once you reach out. Welcome to consult!【WhatsApp/WeChat/Phone】+86 13837122632

Parameters of the Automatic Paper Plate Machine

Product Parameters

The following are the specific parameters of the equipment, helping enterprises accurately evaluate production adaptability:

| Paper plate size: | 2–12 inches (mold exchangeable) |

| Raw material: | Raw Material: Paper/paperboard, aluminum foil coated paper, one side PE coated paper or other |

| Suitable paper weight: | 100–500 gsm (gram a square meter) |

| Rated productivity: | 100–150 pieces/minute (total two stations, about 6000–9000pcs per hour) |

| Total power: | 8.5 KW |

| Power source: | 380V 50Hz or other required |

| Total weight: | 2000 Kg |

| Package size (L x W x H): | 3.0m x 1.7m x 1.7m |

| Air source: | Air compressor in the building, the client does not need to buy an air compressor |

YG’s automatic paper plate machine can flexibly adapt to raw materials of different specifications. It supports producing paper plates with a diameter of 8 – 30cm (corresponding to the 2-12 inches size range). With a production speed of 100 – 150 pieces per minute (two stations, about 6000-9000 pieces per hour), it meets diverse needs from small-scale trial production to large-scale mass production, providing enterprises with flexible production options.

Production Process of Paper Plates

Paper Plate Production Process

- Paper Feeding and Suction: The equipment automatically conveys paper, and the paper suction device grabs it accurately, ensuring stable raw material supply.

- Mold – entering and Positioning: Magnets control the paper position, sliding the paper pieces into the mold precisely to ensure processing accuracy.

- Pressurization and Shaping: Through two-time pressurization molding, and with high-efficiency booster cylinders, it achieves tight shaping. It can press round, rectangular, special-shaped and custom-shaped paper plates, dishes, and trays.

- Demolding and Retrieving: After shaping, it automatically demolds and retrieves the finished products. The whole process requires no manual intervention, being efficient and precise.

Core Features of YG Machinery’s Disposable Paper Plate Making Machine

- Intelligent and Efficient: Adopting an advanced PLC control system, high-efficiency booster cylinders, and solenoid valves. As a professional paper plate making machine supplier, the equipment runs stably, and its processing efficiency far exceeds that of traditional models.

- Safe and Reliable: Equipped with automatic shutdown for fault detection to avoid fault expansion. Meanwhile, magnet-controlled paper positioning ensures operation safety.

- Stable Quality: The two-time pressurization molding technology ensures regular shapes and consistent quality of finished products, meeting high-standard production requirements.

- Flexible and Controllable: Each workstation is controlled separately. Parameters can be adjusted according to production needs, adapting to multi-specification product processing. Whether you care about plastic plate machine price or the performance of paper plate machines, you can find a suitable solution.

Choose Automatic Paper Plate Machine, Trust YG for Peace of Mind

YG Machinery, as a senior paper plate making machine supplier, its equipment demonstrates professionalism and reliability from parameters to functions. The equipment is not only an efficient disposable paper plate making machine but also helps enterprises reduce long-term production costs. If you compare the plastic plate machine price and value the cost-effectiveness, and stability of paper plate machines more, choosing YG is definitely right. Purchase with confidence and start an efficient production journey! In addition, YG Machinery also has high-quality equipment such as paper bowl machines, paper box machines, toilet paper machines, and napkin paper machines. Welcome to contact us at any time!【WhatsApp/WeChat/Phone】+86 13837122632