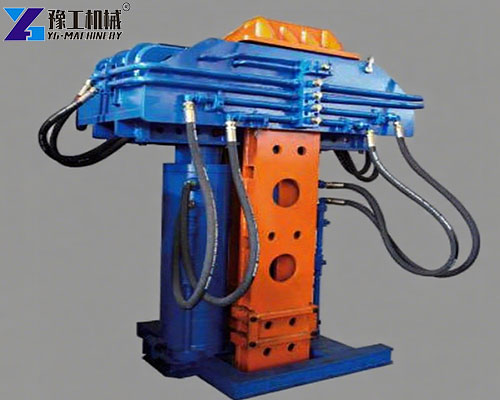

In the modern scrap vehicle recycling industry, the car dismantling shear has become one of the core pieces of equipment. Compared with traditional cutting methods, this excavator-mounted shear can easily complete vehicle dismantling and material separation, significantly improving efficiency and safety. Whether it’s metal, wiring, or electronic components, all parts can be quickly and precisely separated, helping recycling companies maximize utilization and increase revenue. Contact us now for a customized quote!【WhatsApp/WeChat/Phone】+86 13837122632

Product Specifications

To meet different working conditions and machine requirements, YG offers multiple models of hydraulic car scrap shear. The specifications are as follows:

| Model | YG-90 | YG-180 | YG-300 |

| Suitable Excavator (T) | 6-9 | 12-18 | 20-30 |

| Working Pressure (Mpa) | 27.5 | 35 | 35 |

| Overall Length (mm) | 1850 | 2250 | 2650 |

| Overall Weight (kg) | 950 | 1620 | 2150 |

| Maximum Opening (mm) | 570 | 750 | 930 |

| Throat Depth (mm) | 580 | 760 | 940 |

| Blade Length (mm) | 280 | 380 | 480 |

| Central Shear Force (KN) | 830 | 1500 | 2300 |

As shown in the table, different models of excavator car dismantling shear can match excavators from 6 to 30 tons, meeting the needs of small, medium, and large-scale dismantling operations.

Working Principle

The working principle of an excavator scrap car shear is simple. It converts the hydraulic power from the excavator into the shear’s mechanical cutting force. When the operator issues commands from the cab, hydraulic oil is pumped into the shear’s cylinders, causing the pistons to extend and retract, which opens and closes the shear’s jaws. The sharp, durable blades apply enormous pressure to vehicle components, instantly cutting through frames, pipes, and other materials. The entire process requires no manual operation, making vehicle dismantling safe, fast, and efficient.

Core Advantages of Car Dismantling Shear

- High-strength, lightweight design: The shear is made of high-strength, wear-resistant steel, ensuring durability while reducing overall weight, making vehicle dismantling easier and faster.

- Exceptional cutting force: Equipped with large-diameter high-pressure cylinders, the shear delivers about 20% more cutting force than similar products, effortlessly slicing through frames and reinforced steel plates.

- Inverted cylinder installation: This design protects the piston rods, prolongs service life, and reduces maintenance costs.

- Wear-resistant, replaceable blades: The blades are made from high-toughness steel, capable of cutting through metal with ease. All four sides are interchangeable, significantly reducing wear and improving cost-effectiveness.

- High material recovery rate: Using an excavator vehicle dismantler, electric components, metals, and wiring can be precisely separated, improving recovery efficiency and sorting accuracy.

Application Scenarios

Whether in scrap car recycling facilities, steel recycling plants, or large dismantling sites, the hydraulic car scrap shear plays an essential role. Its high cutting efficiency saves labor and time, making complex vehicle dismantling work simple and manageable.

In high-intensity working environments, the stability and safety of the excavator car dismantling shear stand out. It protects operators while helping companies increase output and achieve considerable economic benefits.

Why Choose Car Dismantling Shear?

- Efficiency improvement: Fast operation saves time and shortens project duration. With its high cutting speed and smooth hydraulic performance, multiple vehicles can be dismantled within hours, greatly increasing overall productivity.

- Safety and reliability: Reduces high-risk manual cutting and lowers operational hazards. Operators are protected from sharp metal edges and flying debris, making workplace safety much easier to maintain in busy dismantling environments.

- Cost control: Durable parts reduce replacement frequency and maintenance expenses. The wear-resistant, interchangeable blades and sturdy hydraulic components minimize downtime, saving significant maintenance costs over the equipment’s lifespan.

- Eco-friendly recycling: Supports sorted material recovery and promotes resource reuse. By separating metals, wiring, and electronic components accurately, this equipment ensures maximum recycling efficiency, reducing waste and environmental impact.

For companies pursuing efficient dismantling and recycling, a car dismantling shear is not just a tool—it is a key asset for improving competitiveness.

Contact us now for a personalized quote. Additionally, YG Machinery also offers high-quality excavator attachments, including rippers, rock saws, pile drivers, and pile pullers.【WhatsApp/WeChat/Phone】+86 13837122632