In the scale competition of the egg industry, is the packaging stage’s capacity bottleneck dragging down your delivery speed and eroding your profit margins? Feeling both pleased and anxious when facing large orders? The key to solving the problem lies in the heart of the production line — a continuously and stably outputting egg carton machine. A medium-to-large device with a hourly output of 2500 to 7000 pieces is no longer a simple production tool, but a strategic asset that upgrades an enterprise from a “production unit” to a “profit engine.”【WhatsApp/WeChat/Phone】+86 13837122632

Egg Box Making Machine Parameters

| Model | Output per Hour | Power per Hour | Power Supply | Weight | Main Machine Dimensions | Paper Consumption per Hour | Water Consumption per Hour | Drying Method |

| YG-2500 – 3X4 | 2,500 pieces | 55kw | 380V 50HZ | 4000kg | 2900*1800*1800 mm | 200kg | 400kg | Brick Kiln or Multi-layer |

| YG-3000 – 4X4 | 3,000 pieces | 60kw | 380V 50HZ | 4800kg | 3250*1800*1800 mm | 240kg | 480kg | Brick Kiln or Multi-layer |

| YG-4000 – 4X8 | 4,000 pieces | 95kw | 380V 50HZ | 7000kg | 3250*2300*2500 mm | 320kg | 640kg | Brick Kiln or Multi-layer |

| YG-5000 – 5X8 | 5,000 pieces | 95kw | 380V 50HZ | 8000kg | 3700*2300*2500 mm | 400kg | 800kg | Brick Kiln or Multi-layer |

| YG-7000 – 6X8 | 7,000 pieces | 120kw | 380V 50HZ | 10000kg | 3200*2300*2500 mm | 480kg | 960kg | Brick Kiln or Multi-layer |

Why Is the High-Output Egg Carton Machine the Inevitable Choice for Scaled Production?

Investing in a high-capacity egg tray machine is essentially a pursuit of production “marginal benefits.” An hourly capacity of several thousand pieces means:

- First, the fixed costs allocated to each unit (such as labor, management, depreciation) are sharply diluted, directly improving profit margins.

- Second, it can seamlessly match centralized procurement orders from large supermarkets and food processors, ensuring continuity and reliability of supply — the cornerstone for building long-term partnerships.

The Three Technical Pillars That Reveal High-Output Stability

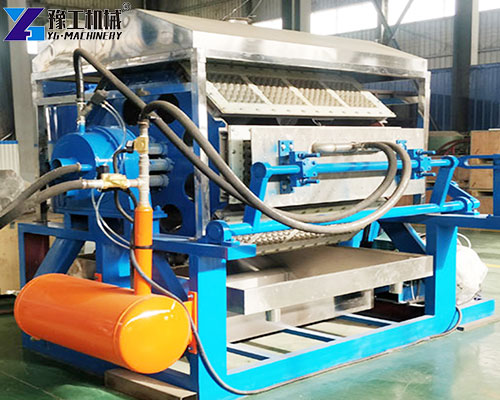

A reliable egg tray manufacturing machine depends on a solid mechanical foundation for continuous and stable operation:

• Pillar One: Precision drum forming system. Using a “multi-side pulp suction, single-side transfer” design (such as 4X4, 8X8) achieves highly automated continuous operations of pulp adsorption, forming and transfer — the physical core of high capacity.

• Pillar Two: Top-tier drive and control core. Fitted with Taiwanese precision indexers and heavy-duty worm gear reducers (or WPA series), ensuring precise synchronization of each station’s movements; paired with well-known brand speed-regulating motors and electrical components to make equipment run smoothly with adjustable speeds.

• Pillar Three: Construction that exceeds standards. The main frame is welded from national-standard steel, and key water-contacting parts are upgraded to 304 stainless steel, resisting corrosion from the root and ensuring ultra-long service life under humid working conditions.

Value Extension Through Multi-purpose Capability

The excellence of modern egg box making machine lies in its powerful functional extensibility. By changing molds, it can easily produce coffee cup trays, fruit pads, and various industrial inner-packaging with heights within 8 cm. This flexibility greatly broadens channels for return on investment, allowing one machine to respond to diversified market demands.

How to Evaluate the Value Connotation of Egg Tray Machine Price?

A wise investor, when focusing on egg tray machine price pays more attention to the long-term value behind it. A higher initial investment often corresponds to superior materials (such as 304 stainless steel), more precise transmission components (such as Taiwanese indexers), and more stable capacity output. When calculating return on investment, focus on the reduction in per-unit cost and the additional revenue brought by increased capacity, rather than merely comparing initial quotes.

How to Choose the Capacity of Your Egg Carton Machine?

When facing a capacity range from 2500 to 7000 pieces, the key to model selection is “matching”:

- Demand analysis: Based on current order peaks and growth expectations for the next 1–2 years, choose a model with 20%–30% spare capacity to avoid short-term equipment bottlenecks.

- Condition check: Carefully verify whether the equipment’s installation dimensions, weight, and power consumption match your factory space, floor load capacity, and electrical configuration to ensure it “fits and can be used.”

Why Choose Our Egg Carton Machine Manufacturing Solution?

Our egg tray manufacturing machine solutions not only provide a full model spectrum from 2500 to 7000 pieces per hour, but also emphasize the long-term running quality of every machine. From a solid frame made of national-standard steel to branded configurations for critical components, we are committed to making every egg tray machine the most reliable and durable link in your production line.

In summary, choosing a suitable high-capacity egg box making machine is a strategic decision related to production efficiency and market competitiveness. It is not only a tool for increasing output, but a core driver that continuously reduces cost and increases efficiency through stability, flexibility, and economy. Before making the final decision, be sure to comprehensively consider technical details, capacity matching, and total lifecycle cost to select the production engine that best fits you.【WhatsApp/WeChat/Phone】+86 13837122632