In Ghana, a local egg tray seller is facing the sweet burden of market expansion. As its business volume grows, its existing production efficiency can no longer meet the ever-increasing order demand. To seize market opportunities and consolidate competitive advantages, it decided to invest in upgrading production equipment. After multiple comparisons, it finally imported the YG-3000-4X4 model egg carton maker from YG Machinery.【WhatsApp/WeChat/Phone】+86 13837122632

Egg Tray Production Machine Parameters

| Model | Capacity/hour | Power/hour | Voltage | Weight |

| YG-3000 – 4X4 | 3000pcs/hour | 60kw | 380V50HZ | 4800kg |

| Dimensions (main machine) | Paper consumption/hour | Water consumption/hour | drying | |

| 3250*1800*1800 | 240kg | 480kg | multi-layer drying | |

Clarify Customer Needs

- Urgent need to increase production capacity: The existing supply capacity cannot match the centralized procurement needs of downstream customers (such as large farms and supermarkets). There is an urgent need for a high-yield egg tray production machine to rapidly increase the daily shipment volume.

- Ensure supply stability: Relying on external procurement or inefficient production will lead to unstable delivery cycles. The customer needs to establish an independent and controllable production line to ensure the continuity and reliability of supply, so as to maintain business reputation.

- Control comprehensive costs: While increasing production capacity, it is necessary to comprehensively consider equipment procurement costs, production energy consumption (electricity and water) and labor costs to seek the optimal return on investment.

- Simple operation and maintenance: As a seller, production management is not its traditional strength. Therefore, the equipment must be highly automated, with a user-friendly interface and simple daily maintenance.

How YG Egg Carton Maker Achieves Efficient and Stable Production

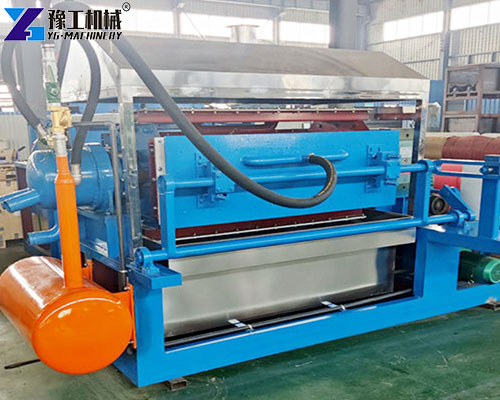

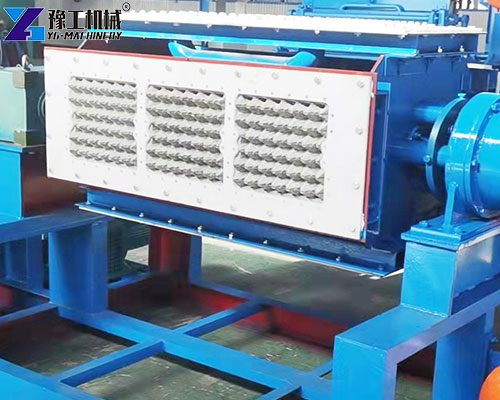

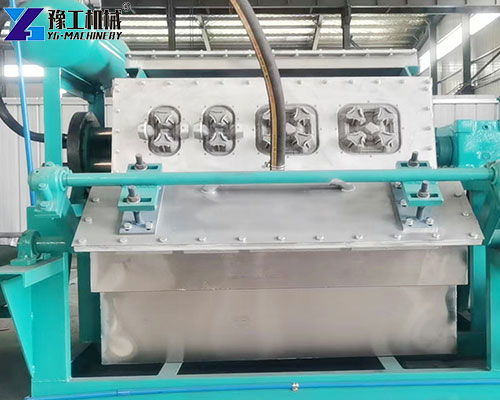

- High-capacity design to meet expansion ambitions: As a rotary drum type egg carton making machine, its design of “four-sided pulp suction and four-sided transfer” achieves an excellent efficiency of up to 3,000 pieces per hour. This directly responds to the customer’s core demand for increasing production capacity, enabling it to easily handle large orders.

- Stable operation to guarantee reliable supply: The whole machine is welded with national standard steel, and core transmission components such as Taiwan precision indexers and worm gear reducers ensure the precision and durability of long-term operation. This means that this Egg Carton Maker can continuously and stably output products, eliminating the risk of supply interruption caused by frequent equipment failures.

- Economical energy consumption to optimize production expenses: The whole system is scientifically designed, with power consumption of 60kw per hour and water consumption of 480kg, which is an energy-efficient type among equipment of the same production capacity. The multi-layer drying line further improves the thermal energy utilization rate, helping customers effectively control the variable costs of daily operations.

- Simple operation to reduce management difficulty: Equipped with well-known electrical and pneumatic components, it is easy to operate and runs smoothly, which greatly reduces the dependence on skilled technicians, and is very suitable for the customer’s smooth transition from sales to production management.

Value Brought by Egg Tray Maker Machine

Several months after the equipment was put into operation, the customer gave a high evaluation: “Purchasing this YG egg tray maker machine is the most correct business decision we made this year. Now we can independently control the output and delivery time, and no longer worry about supply chain disruption. This equipment is like an indefatigable right-hand man, with stable output and consistent quality, giving us an absolute initiative when facing competitors.”

YG Provides More Than Just an Egg Carton Maker

Among numerous egg tray production machine suppliers, the customer chose YG based on the following key considerations:

- Targeted technical solutions: YG provides not just a single machine, but a complete production system solution including pulping, forming and drying, and the configuration is fully matched to Ghana’s industrial environment and the customer’s actual production capacity goals.

- Achieve the best balance between quality and cost-effectiveness: YG insists on using high-quality brands for key components to ensure core durability; at the same time, it pursues high efficiency and practicality in the overall design, providing customers with the optimal long-term investment value.

- Reliable after-sales support: From installation and commissioning, personnel training to subsequent technical consulting, YG has established a sound service response system to ensure that customers far away in Ghana can put into production and operation without worries.

For entrepreneurs planning to enhance market competitiveness by improving independent production capacity in Ghana and even West Africa, choosing a reliable egg carton making machine is crucial. With its excellent performance and reliability, YG Egg Carton Maker has become the common choice of many successful enterprises in the region. Contact us now, and let YG help you achieve a leap in production efficiency and expansion of your business territory.【WhatsApp/WeChat/Phone】+86 13837122632

No responses yet