As environmental protection packaging has increasingly become a global consensus, producing packaging products such as egg trays and fruit trays from waste paper is not only a sensible business decision, but also a reflection of corporate social responsibility. A workman must first sharpen his tools if he is to do his work well. Choosing an efficient, stable and suitable egg carton making machine is the first step to successfully entering the pulp molding industry.【WhatsApp/WeChat/Phone】+86 13837122632

Egg Crate Making Machine Parameters

| Model | Type | Output (pcs/hour) | Power (kW/hour) | Total Machine Weight | Feature Summary |

| YG-1000 – 3X1 | Flip Type | 1000 | 38 | 2500kg | High cost performance, ideal for beginners |

| YG-1500 – 4X1 | Flip Type | 1500 | 38 | 3000kg | Mature technology, increased production capacity |

| YG-2500 – 3X4 | Rotary Type | 2500 | 55 | 4000kg | Smooth operation, significant efficiency |

| YG-3000 – 4X4 | Rotary Type | 3000 | 60 | 4800kg | Adjustable speed, easy operation |

| YG-4000 – 4X8 | Rotary Type | 4000-4500 | 95 | 7000kg | Large-scale production capacity, equipped with drying system |

Egg Carton Making Machine Categories: Flip Type or Rotary Type Machine?

YG provides two major categories of equipment to meet the needs of customers of different scales. Understanding their differences is the key to equipment selection:

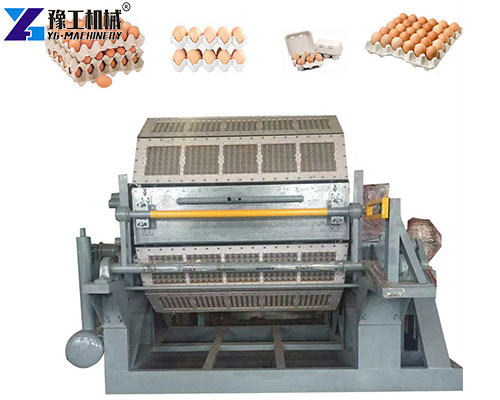

1. Flip Type: A cost-effective choice for entry-level and flexible production

- Positioning: Suitable for start-ups, small farms or customers requiring flexible production. The hourly output ranges from 1000 to 1500 pieces.

- Core Advantages: Low investment cost, capable of producing various special-shaped trays with a height of no more than 8 cm, such as standard egg crates and egg cartons, with strong flexibility.

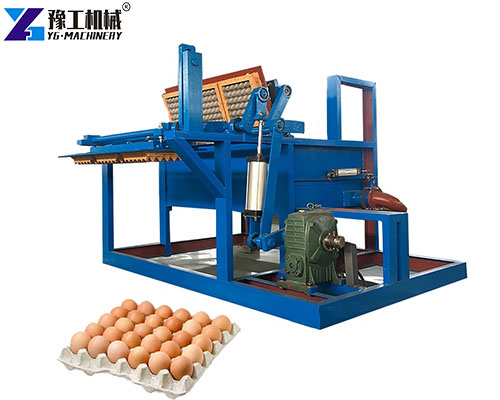

2. Rotary Type: An efficient and stable engine for large-scale production

- Positioning: Targeted at medium to large professional manufacturers pursuing economies of scale. The hourly output covers 2500 to 7000 pieces.

- Core Advantages: Adopting rotary drum multi-sided circulating pulp suction, it operates extremely smoothly with a high degree of automation and large hourly production capacity, making it the core equipment for building a modern egg box making machine workshop.

YG-1000 vs. YG-1500 Egg Carton Making Machine

Both models adopt reliable mechanical transmission structures, serving as a solid foundation for small-scale production.

1. YG-1000 – 3X1: A Stable Cornerstone for Entry-level Users

As a classic entry-level model of egg carton making machine, it lowers the industry threshold with its simple “one-button start-stop” operation and low price. The main machine adopts national standard steel and worm gear reducer, which is durable and reliable, very suitable for customers who have just entered the packaging industry for trial production and small-batch production.

2. YG-1500 – 4X1: An Efficient Upgrade for Production Capacity

On the basis of YG-1000, the forming surface is lengthened to produce 4 pieces per mold. Without increasing power consumption and labor costs, the production capacity is increased by 50%. This design reflects the wisdom of maximizing output with limited investment. With mature technology and stable operation, it is the preferred choice for the upgrading of small production lines.

A Leap in Production Capacity from YG-2500 to YG-4000 Egg Carton Making Machine

The rotary drum machine series represents a higher level of automated production.

1. YG-2500/3000 Series: The Backbone of Medium-sized Production

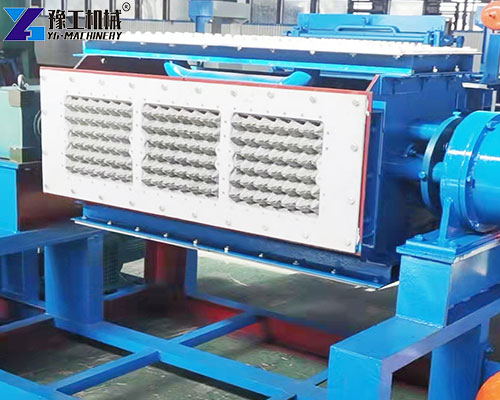

Take YG-3000 – 4X4 as an example. This egg tray manufacturing machine adopts a four-suction and four-sided rotary drum and Taiwan precision indexer to ensure the accurate operation of each station. The application of a variable speed motor allows the production speed to be flexibly adjusted according to the process, with easy operation and stable running, which can meet the dual needs of most medium-sized customers for production capacity and stability.

2. YG-4000 – 4X8: The Powerful Heart of Large-scale Manufacturing

As the production capacity leader of the series, it adopts an eight-sided pulp suction design with an hourly output of more than 4000 pieces. Its key components are made of 304 stainless steel and heavy-duty WPA-175 reducer, specially designed for continuous high-intensity work. This model is usually equipped with brick kilns or multi-layer drying lines to form a complete egg box making machine production system, suitable for large-scale manufacturers with ambitious goals.

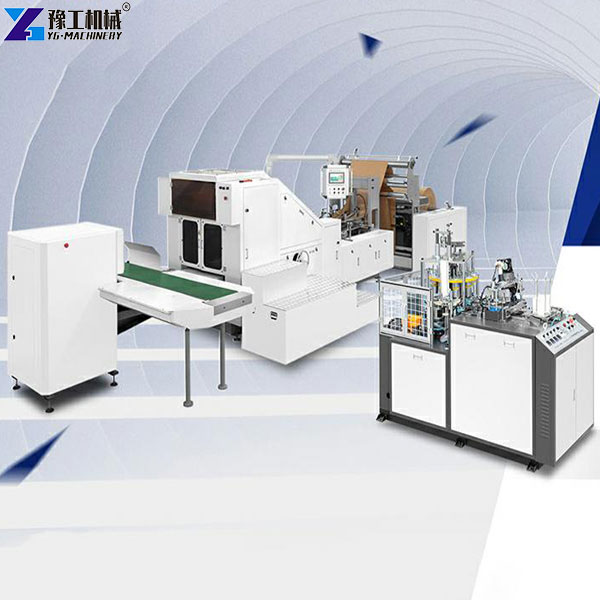

Diversified Product Blueprint of Egg Carton Making Machine

Investing in a YG equipment brings far more than just a machine for producing egg trays. By replacing molds, the same egg carton making machine can be easily transformed to produce coffee cup holders, fruit trays, bottle trays and various exquisite inner packaging for industrial products. This “one machine with multiple functions” feature greatly expands your business boundaries, helping you flexibly respond to market changes and seize more business opportunities.

Quality and Craftsmanship Assurance of YG Equipment

Behind the performance parameters lies solid manufacturing craftsmanship:

- Robust Structure: All main machines are welded with national standard steel to ensure no deformation under long-term load-bearing.

- Reliable Transmission: From worm gears to Taiwan precision indexers, the transmission system is accurate and durable.

- High-quality Supporting Parts: Equipped with well-known domestic motors, electrical appliances and pneumatic components to ensure the coordinated and stable operation of various systems.

- Complete System: From pulping and forming to vacuum and air compression, each set of equipment provides a complete turnkey solution to ensure your smooth production launch.

How to Make a Wise Choice?

Choosing the most suitable egg tray manufacturing machine requires comprehensive consideration of the following factors:

- Production Capacity Positioning: Evaluate current market demand and growth plans for the next 1-3 years.

- Investment Budget: Balance initial equipment investment and expected return cycle.

- Product Planning: Clarify whether the core product is egg trays or needs to be compatible with other molded products.

- Production Space: Ensure that the site can accommodate the main machine and supporting pulping and drying equipment.

From cost-effective flip type to efficient and powerful rotary type, the YG series equipment provides a clear and reliable technical path for entrepreneurs and producers at different stages. Choosing YG is not only choosing a high-quality egg crate making machine, but also choosing a trustworthy partner with profound manufacturing experience. Let us help you transform the concept of environmental protection into a sustainable and successful business.【WhatsApp/WeChat/Phone】+86 13837122632