Many entrepreneurs and packaging enterprises are actively seeking a green production solution with low investment threshold and stable returns. The flip-type egg tray maker machine is an ideal entry-level device developed precisely to meet this demand. It does not require huge investment, but with excellent flexibility and cost-effectiveness, it can help you quickly enter the pulp molding packaging market.【WhatsApp/WeChat/Phone】+86 13837122632

Egg Tray Production Machine Parameters

| Model | Output (pcs/hour) | Power (kW/hour) | Power Supply | Total Machine Weight | Main Machine Dimensions (L×W×H) | Paper Consumption/Hour | Water Consumption/Hour | Drying Method |

| YG-1000 – 3X1 | 1000 pcs | 38kw | 380V 50HZ | 2500kg | 2600×2200×1900mm | 80kg | 160kg | Natural Air-Drying |

| YG-1500 – 4X1 | 1500 pcs | 38kw | 380V 50HZ | 3000kg | 2800×2200×1900mm | 120kg | 240kg | Natural Air-Drying |

Who Needs a 1000-1500pcs/h Egg Tray Maker Machine?

Flip-type equipment is not a one-size-fits-all solution, but it accurately addresses the core pain points of specific customer groups:

- Startups and individual entrepreneurs: With limited budgets, they need to control initial investment risks and seek a reliable platform for trial production and initial operation.

- Small and medium-sized poultry farms or cooperatives: They hope to achieve self-sufficiency in packaging, reduce procurement costs, and flexibly control output.

- Factories seeking business transformation: They plan to add an eco-friendly packaging production line, but need to start with small batches to verify the market and production processes.

- Regional small-scale packaging suppliers: Serving the local market, with a daily output demand of 10,000-30,000 pieces, they pursue fast turnover and flexible order fulfillment.

Why Choose a 1000-1500pcs/h Egg Tray Maker Machine?

Compared with medium and large rotary drum machines, flip-type machines demonstrate irreplaceable unique advantages at the entry stage:

- Ultimate cost-performance ratio for investment: This is the most prominent advantage. The initial purchase cost is much lower than that of large-scale equipment. Meanwhile, as shown by the YG-1500 model, it can increase production capacity by 50% through optimized design without additional power and labor input, minimizing the unit cost.

- Excellent production flexibility: Thanks to its mold structure, it can easily produce various special-shaped products with a height of less than 8 cm. You can produce egg trays today, and switch to making coffee cup holders, egg cartons or small industrial liners tomorrow by replacing the molds—one machine meets diverse needs.

- Low operational complexity: Adopting classic worm gear mechanical transmission and “one-button start-stop” control, the system is stable with low failure rate. It has relatively low technical requirements for operators and maintenance personnel, saving training and maintenance costs.

Power and Efficiency: Unveiling the Stable Production Core

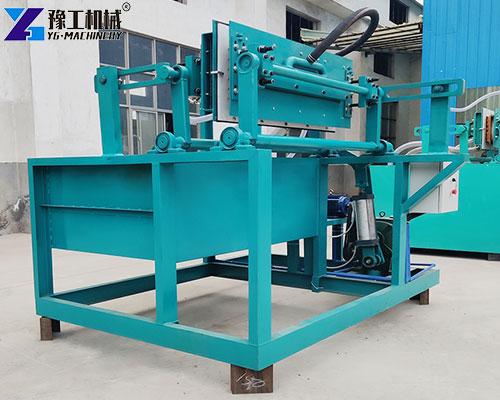

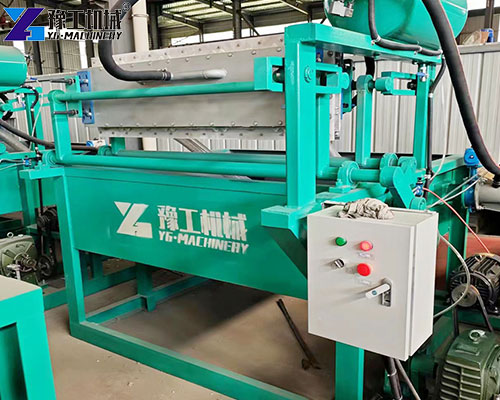

The reliability of the flip-type egg tray maker machine stems from its solid traditional mechanical design:

- Robust and durable main machine structure: The whole machine is welded with national standard steel, ensuring structural strength and service life in long-term humid environments.

- Reliable power and transmission system: Equipped with well-known domestic motors and classic worm gear reducers, it features stable and reliable power transmission as well as simple maintenance.

How to Choose Between YG-1000 and YG-1500 Egg Tray Production Machine?

When faced with these two main models, your choice should be based on an accurate self-assessment:

- Choose YG-1000 – 3X1 if: Your startup capital is more limited, your daily output demand is less than 10,000 pieces, and you hope to verify your business model and production technology at the lowest cost. It is a pure “entry cornerstone” with the most attractive price.

- Choose YG-1500 – 4X1 if: After evaluation, you have clear, stable and growing market demand, and pursue higher production efficiency and better energy consumption per piece. It achieves higher output with the same power and labor input, making it a sensible upgrade choice for balancing short-term cost-effectiveness and medium-term production capacity.

Exploring the Composition of Egg Tray Making Machine Price

Price is not a single figure; understanding its value composition is crucial:

- Core main machine cost: Depends on the model, materials (e.g., national standard steel) and brand of core components.

- Mold investment: This is the key to achieving product diversification. The standard configuration includes egg tray molds initially, and additional molds for other products can be purchased later according to market needs.

- Hidden value—technology and craftsmanship: The high yield rate, low downtime and production stability brought by mature equipment design are greater “values” in long-term operation, far superior to simply pursuing a low initial quotation.

Success Case of Small Egg Tray Making Machine

A typical success story: A poultry egg distributor in Nigeria invested in a complete production line including YG-1500 equipment to produce egg trays for self-use. After meeting his own needs, he took advantage of the machine’s flexibility to undertake fruit tray orders from surrounding small fruit stores. He not only recovered the cost quickly, but also expanded his business from sales to packaging production with this small egg tray making machine as the core, enhancing his comprehensive competitiveness.

How to Obtain Customized Solutions and Accurate Quotes?

To get an accurate egg tray making machine price and feasible solution, we recommend:

- Clarify core needs: Evaluate main products, expected daily output and budget range.

- Request detailed information: Contact us to obtain more comprehensive technical documents, success case videos and customer testimonials.

- Get a full-package quotation: We will provide a transparent full-package quotation based on all your needs.

For you who seek a steady start in the eco-friendly packaging field, a well-designed, cost-effective flip-type egg tray maker machine is undoubtedly the most practical choice. It opens the door to the pulp molding world for you with minimal investment risks. Choosing YG is not only buying an egg tray production machine, but also gaining a reliable professional partner that grows with you.【WhatsApp/WeChat/Phone】+86 13837122632