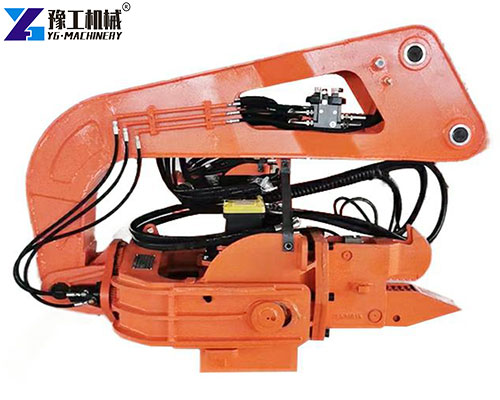

Are you looking for a cleaner and more efficient way to cut rock and reinforced concrete? An Excavator Rock Saw Attachment that fits your excavator is exactly the answer. It is not only a tool upgrade, but also an important investment to enhance project competitiveness and control overall costs.【WhatsApp/WeChat/Phone】+86 13837122632

Excavator Rock Saw for Sale Parameters

| Model | Max Flow | Max Pressure | Output Speed | Output Torque | Blade Size (mm) | Excavator Weight |

| YPJ-80 | 150 L/min | 320 bar | 0–550 | 1580 Nm | 800–1600 | 3–8 tons |

| YPJ-150 | 180 L/min | 320 bar | 0–500 | 2100 Nm | 1400–2000 | 8–16 tons |

| YPJ-200 | 260 L/min | 320 bar | 0–450 | 3500 Nm | 1600–2400 | 15–25 tons |

| YPJ-300 | 320 L/min | 320 bar | 0–400 | 4500 Nm | 1800–2800 | 20–30 tons |

| YPJ-400 | 380 L/min | 320 bar | 0–350 | 6800 Nm | 2000–3200 | 25–35 tons |

| YPJ-500 | 420 L/min | 320 bar | 0–300 | 8500 Nm | 2000–3800 | 35–50 tons |

| YPJ-300 Dual | 320 L/min | 320 bar | 0–250 | 7000 Nm | 2000–3500 | 20–36 tons |

| YPJ-400 Dual | 380 L/min | 320 bar | 0–250 | 9000 Nm | 2000–3500 | 25–45 tons |

Customer Needs

Our customers are faced with the following types of needs:

- Pursuing Higher Efficiency: In mining and large-scale earthwork projects, customers need to process rock formations faster than breakers to shorten the construction period.

- Requiring Precision and Controllability: In building demolition, pipeline trench excavation or stone mining, it is necessary to obtain flat and regular cutting surfaces to reduce secondary trimming work.

- Meeting Environmental and Safety Restrictions: During urban renewal, operations near residential areas or construction near national parks, it is necessary to significantly reduce the risks of noise, vibration and flying rocks caused by blasting and crushing.

- Seeking Equipment Versatility: Customers hope that their existing excavators can be multi-purpose by changing attachments, handling various tasks from rock cutting to reinforced concrete demolition, and improving return on investment.

Excavator Rock Saw Attachment Outstanding Performance

To meet the above needs, our hydraulic saw for excavator focuses on core performance and reliability in design:

- Powerful Cutting Core: Adopting special alloy steel saw blades, optimized for granite and basalt, with excellent wear resistance. The powerful hydraulic system provides high torque output to ensure a stable and powerful cutting process.

- Intelligent Safety and Adaptability Design: Integrated with a quick braking device, it responds instantly to sudden saw jamming; the saw blade supports reverse rotation, which can flexibly handle different jamming situations.

- Flexible Customization Options: We offer a variety of styles from single-saw blade to double-saw blade, and can customize according to customers’ special needs (such as extreme working temperature, specific cutting depth). A saw blade cooling system is optional to ensure continuous operation even in Australia’s hot environment.

- Wide Equipment Compatibility: The product is designed to be quickly connected with mainstream brands and various tonnages of excavators on the market. Customers can upgrade their existing equipment into an efficient rock cutting platform without investing in new mainframes.

Customer Feedback

One of our high-performance excavator rock saw attachment was purchased by an infrastructure-focused contractor in Queensland for a drainage tunnel expansion project near Brisbane.

- Project Challenge: It was necessary to accurately cut a new tunnel entrance section in the existing concrete structure and natural sandstone. The working space was narrow, and the vibration impact on the surrounding structures had to be minimized.

- Product Application: The customer equipped its 22-ton excavator with the YPJ-300 model. With its high torque of 4500nm and large-diameter saw blade of 2800mm, the equipment successfully completed the high-precision cutting task.

- Direct Feedback: The project director commented: “This hydraulic saw for excavator produces a smooth cutting surface with almost no need for subsequent processing. Most importantly, the vibration it generates is extremely small, which protects the adjacent existing structures—this was the decisive factor for us to choose it.”

Why Our Excavator Rock Saw Attachment Is Your Wise Choice?

Choosing our excavator rock saw attachment means you will get:

- Proven Adaptability to Australian Working Conditions: The product design fully considers the rock hardness and climatic conditions in Australia.

- Full-process Service from Selection to Support: We provide professional technical consulting to ensure that the rock saw attachment for excavator you purchase is perfectly matched with your excavator and construction goals.

- A Key Tool to Enhance Overall Competitiveness: It is not just an attachment, but also a powerful weapon to help you win more bids with higher efficiency and lower overall costs.

Choose YG Excavator Rock Saw Attachment

Whether it is mines, quarries, or complex urban civil engineering, when facing the challenge of cutting hard materials, a powerful excavator rock saw attachment is the key to your project’s success. Our product range is complete, with corresponding solutions for small, medium and large excavators.

If you are looking for a reliable and efficient rock cutting solution in Australia and hope to maximize the potential of your existing equipment, please contact us immediately. Our expert team is happy to provide you with detailed product information, technical parameters and customized consulting for your specific project needs, helping you break through any hard material and complete the project efficiently.【WhatsApp/WeChat/Phone】+86 13837122632

No responses yet