In the highly competitive packaging production field, the paper bag making automatic machine is undoubtedly a “magic tool” to improve efficiency. It can complete a series of processes such as handle making, pasting, paper edge gluing, tube forming, cutting, creasing, bottom gluing, and bottom forming in one go and synchronously, with the whole process operating automatically. However, many enterprises always have many concerns when they want to buy it: Is this equipment really easy to use? What changes can it bring to production? Don’t worry, let’s solve the doubts one by one for you, so that you can make a clear decision!【WhatsApp/WeChat/Phone】+86 13837122632

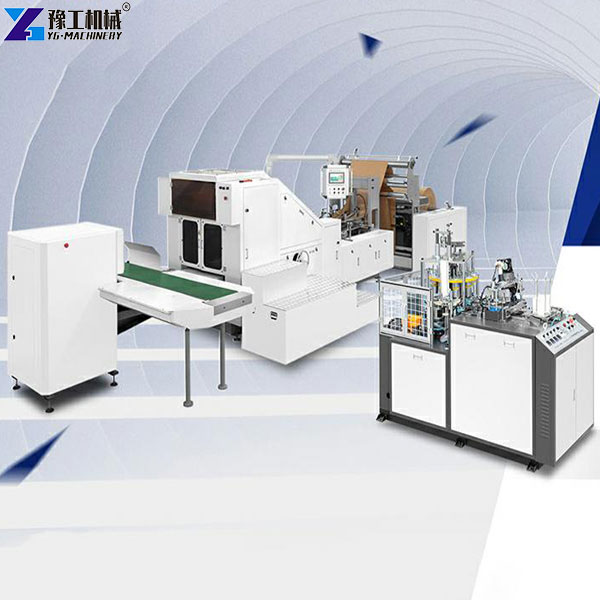

Analysis of Hot-selling Model Parameters of YG Machinery

Take the popular model YG-FD450T under YG as an example, its performance parameters are very impressive.

| Model | YG-FD450T |

| Cutting Length | 270-430mm |

| Paper Bag Width(total) | 240-450mm |

| Bottom Width | 90-180mm |

| Paper gsm(total) | 80-150g/㎡ |

| Material Width(total) | 650-1290mm |

| Paper Material Diameter | 1200mm |

| Paper Core Inner Diameter | 76mm |

| Handle Patch Length | 190mm |

| Handle Patch Width | 50mm |

| Paper Rope Spacing | 95mm |

| Paper Handle Rope Diameter | 3-5mm |

| Handle Patch Paper Roll Width | 100mm |

| Handle Paper Roll Diameter | 1200mm |

| Handle Patch Paper Weight | 100-135g/㎡ |

| Mechanical Speed | 30-180pcs/min |

| Paper Bag Production Speed | 30-150pcs/min |

| Handle Speed | 30-130pcs/min |

| Cutter Method | Pinking |

| Total Power | 380V/ 3Phase 4Line 41.5kw |

| Total Weight | 15500Kg |

| Machine Overall Dimension | 1400060002400mm |

Is Paper Bag Making Automatic Machine Really That Powerful? What Functions Can It Realize?

It’s no exaggeration to say it’s an “all-rounder”! The whole working process of the equipment is very smooth: first, the handle machine makes handles from rope rolls and paper sheet rolls, then sends them to the handle pasting unit through the conveying system, pre-breaks the paper rope position, applies glue to the patch position, automatically pastes the handles on the original or printed roll paper, and then the host completes the subsequent processes such as edge gluing and tube forming, with no manual intervention throughout the process.

It adopts a high-speed motion controller (CPU) imported from Mitsubishi, Japan. It controls the servo operation through a high-speed bus to ensure stable movement and smooth movement curve. Equipped with high-precision sensors, it is super sensitive and monitors the paper tension in real time. The cutting size is accurate to the millimeter level, so you don’t have to worry about different sizes of bags anymore. It can handle kraft paper, white cardboard, or coated paper stably, and can process beautiful bags with any material. It also has an intelligent adjustment function. Input the parameters on the touch screen, and the equipment will adjust automatically immediately. The production change is very fast, and it can easily cope with multi-batch and small-batch production, with efficiency rising rapidly!

Is Paper Bag Making Automatic Machine Widely Applicable? Which Industries Can Use It?

It’s very wide! It is especially suitable for mass production of shopping bags in food, clothing, and other industries. The square bottom paper bags produced are strong, good-looking, and have super bearing capacity. The food industry uses it to pack bread and dried fruits, which is environmentally friendly and safe, meeting the high requirements of food packaging; The retail industry prints the brand logo on the bag, and when customers carry it, it becomes a mobile billboard, helping to build brand reputation.

Now this equipment is a “star product” among paper bag machine for sale. Many packaging factories have directly increased their production efficiency by more than 30% after buying it. Compared with the traditional shopping bag machine, it is more professional in making square bottom paper bags. The bottom of the bag is flat and tightly sealed, which improves the grade at once!

Want to Buy Paper Bag Making Automatic Machine, How to Choose to Avoid Pitfalls?

Choosing the right one can save a lot of trouble! You have to choose according to your own production scale and product needs. We are a reliable paper bag making machine manufacturer. The equipment we produce has superior performance, adopts a Weilun touch screen man-machine interface, with clear operation functions at a glance. It is also equipped with a Japanese Mitsubishi servo motor and a German Sick color mark electric eye correction to accurately track the size of printed bags. We can provide you with customized solutions to ensure that the equipment perfectly matches your production line.

At present, our paper bag machine for sale has models with different production capacities. Whether you are a start-up small factory, or a large-scale production factory, you can find a suitable one. In addition, our shopping bag machine series can also be matched with it to form a complete packaging production line, making production smoother. If you have any questions, please feel free to contact us. Our professional team will help you answer them, so that you can buy and use it with confidence!【WhatsApp/WeChat/Phone】+86 13837122632

No responses yet