In the field of glass processing and curtain wall installation, the demand for efficient, safe, and precise glass handling equipment is increasing rapidly. A glass lifter machine, designed specifically for glass assembly, not only solves the problems of heavy manual labor and high safety risks but also significantly improves construction efficiency. Contact our professional team for more product details and exclusive quotations!【WhatsApp/WeChat/Phone】+86 13837122632

Glass Lifter Machine Parameters

| Model Type | YG-LD-300 | YG-LD-400 | YG-LD-500 | YG-LD-600 | YG-LD-800 | |

| Load Capacity | 300kg(retract)150kg(extend) | 400kg(retract)200kg(extend) | 500kg(retract)250kg(extend) | 600kg(retract)300kg(extend) | 800kg(retract)400kg(extend) | |

| Lifting Height | 3500mm | 3500mm | 3700mm | 3700mm | 4500mm | |

| QTY of Suction Cap | 4pcs | 4pcs | 6pcs | 6pcs | 8pcs | |

| Rubber Suction Cap | 300mm | Ø300mm | Ø300mm | Ø300mm | Ø300mm | |

| Maintenance-free Battery | 2x12V/80AH | 2x12V/100AH | 2x12V/120AH | 2x12V/120AH | 2x12V/120AH | |

| Battery Charger | Smart Charger | Smart Charger | Smart Charger | Smart Charger | Smart Charger | |

| Drive motor | 24V/1200W | 24V/1200W | 24V/1200W | 24V/1200W | 24V/1200W | |

| Lifting Motor | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/6L | 24V/2000W/12L | |

| Chassis L*W | 2660*810mm | 2660*810mm | 2800*810mm | 2800*810mm | 2800*810mm | |

| Driving Wheel | Ø250x80mm | Ø250x80mm | Ø300x100mm | Ø300x100mm | Ø300x125mm | |

| Packing Size(mm) | 2560*1030*1700 | 2560*1030*1700 | 2580*1050*1700 | 2580*1050*1700 | 3000*1250*2300 | |

| N.W/G.W | 1100/1150kg | 1280/1330kg | 1300/1350kg | 1400/1450kg | 1600/1650kg | |

| Loading Qty | 1x20GP/40GP: 6SETS/12SETS | |||||

| Movement | Automatic(4 kinds) | 1. The suction cup frame flips 180° electrically. 2. The support plate automatically retracts. 3. Hydraulic arm lifts electrically. 4. The base of the whole machine moves 100-150mm horizontally. | ||||

| Manual (2kinds) | 1. The suction cup holder can be manually rotated 90 degrees (electrically powered optional). 2. The suction cup holder can be manually rotated 360 degrees (electrically powered optional). | |||||

| Usages | Mainly used for the handling, movement, and installation of materials such as glass, marble, wood, iron plate, etc. | |||||

3 Advantages of Glass Lifter Machine

- Flexible and Adjustable Operation: Equipped with extendable and retractable support arms, the suction frame can rotate 360° and flip 180°. This multi-directional adjustment allows the equipment to adapt to different installation angles and positions, especially for complex curtain wall structures.

- Smart Safety Protection: As a professional glass vacuum lifting device, each suction cup has an independent vacuum control valve, making maintenance simple. It is also designed with a pressure-holding system and alarm function—if there is a sudden power outage, it maintains pressure to prevent accidents caused by falling glass.

- High Efficiency and Labor Saving: Featuring electric lifting and electric walking, it replaces traditional manual handling. It can lift 300–800kg glass panels up to 3.5–5m in height, reducing labor intensity and cost while speeding up project schedules.

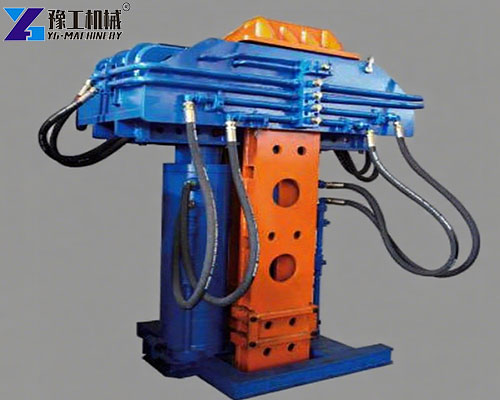

Details Display

- One-piece aluminum alloy structure for durability and rust resistance.

- Thickened extendable arms for safer lifting and lowering.

- High-power lifting rod with strong thrust for easy flipping.

- Equipped with a vacuum accumulator for longer pressure retention and safer use.

- Stabilizing support legs on both sides for smoother operation.

- Optional wireless constant-speed remote control available.

Application Scenarios of Glass Lifting Machine

- Curtain Wall Installation: In high-rise projects, it accurately delivers large glass panels to designated positions. Its strong suction and flexible movement ensure glass safety and installation precision.

- Glass Processing Workshop: Used for transferring glass between processes such as cutting, edging, and tempering. Compared with traditional glass lifting machines, it adapts better to different glass sizes and thicknesses, improving production efficiency.

- Interior Decoration Projects: In malls, hotels, and exhibition halls, it is used for installing glass partitions, railings, and ceiling panels. Its compact design enables work in narrow spaces with low noise, minimizing disruption to surrounding areas.

A glass vacuum lifting equipment is an essential tool in the glass assembly industry, combining flexibility, safety, and efficiency. Whether for large construction projects or small workshops, it plays a vital role. If you are searching for high-quality glass lifting equipment for sale, the YG glass lifter machine is the ideal choice—it improves efficiency, ensures safety, and reduces overall project costs. Contact us now for an exclusive quotation!【WhatsApp/WeChat/Phone】+86 13837122632