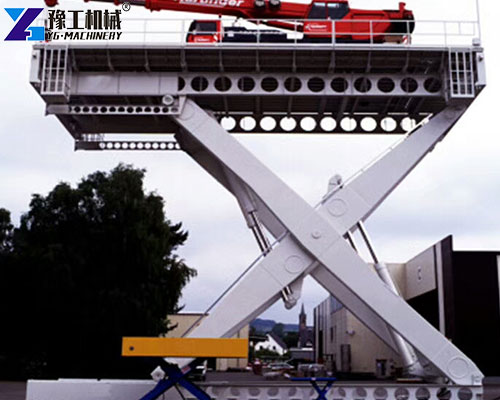

The hydraulic scissor lift platform, with its excellent load-bearing capacity and stable lifting performance, plays a vital role in various fields such as production lines, warehousing logistics, and large equipment assembly. Compared with mobile equipment, it offers higher safety and stability, making it particularly suitable for industrial environments that require long-term and stable operation.【WhatsApp/WeChat/Phone】+86 13837122632

Hydraulic Scissor Lift Platform Parameters

| Model | Rated Load (kg) | Minimum Height (mm) | Lifting Stroke (mm) | Maximum Height (mm) | Platform Size (mm) | Lifting Time (s) | Total Weight (kg) | Power Voltage (v) |

| YG0.3-0.6 | 300 | 200 | 600 | 800 | 1200×900 | 8 | 360 | AC-380 |

| YG0.5-1.1 | 500 | 230 | 1100 | 1330 | 1680×1000 | 5 | 480 | AC-380 |

| YG1-1 | 1000 | 240 | 1000 | 1240 | 1500×1500 | 22 | 650 | AC-380 |

| YG2-1 | 2000 | 240 | 1000 | 1240 | 2000×1500 | 40 | 950 | AC-380 |

| YG3-1 | 3000 | 340 | 1000 | 1340 | 2500×1200 | 20 | 1250 | AC-380 |

| YG4-1 | 4000 | 340 | 1000 | 1340 | 1700×500 | 40 | 1400 | AC-380 |

| YG5-1.1 | 5000 | 380 | 1100 | 1480 | 2200×1350 | 40 | 1620 | AC-380 |

Advantages of Hydraulic Scissor Lift Platform

The fixed hydraulic scissor lift platform offers multiple advantages that make it outstanding in industrial applications:

- Superior structural stability: The platform adopts a reinforced scissor structure, and the overall frame is precisely calculated and optimized to ensure smooth operation under full load, effectively avoiding shaking and tilting.

- Reliable hydraulic system: Equipped with a high-performance hydraulic power unit, it provides smooth and shock-free lifting with excellent sealing performance, preventing leakage and ensuring long-term reliability.

- Wide adaptability: From light to heavy loads, and from low to high travel ranges, diverse model configurations meet various industrial needs, making it an ideal solution for multiple material handling tasks.

- High-quality materials and craftsmanship: All steel parts are shot-blasted to remove surface oxides and impurities, significantly improving welding quality and paint adhesion, extending the equipment’s service life.

Main Applications of Scissor Lift Heavy Duty

- Production line operations: Used to transfer materials between production lines of different heights, achieving seamless process connections and improving efficiency and automation.

- Warehousing and loading areas: Works with forklifts and other handling vehicles to enable fast loading, unloading, and stacking of goods, optimizing warehouse space and reducing labor intensity.

- Large equipment assembly: In machinery manufacturing and automobile assembly industries, it provides height adjustment functions for large components, ensuring precision and efficiency during assembly.

- Machine tool loading and unloading: Assists large machine tools with accurate height matching for safe and fast material transfer.

Features of Hydraulic Scissor Lift for Sale

- Intelligent control system: Integrates electro-hydraulic design with easy and intuitive operation. Control methods can be customized based on actual needs, achieving precise position control and stable performance output.

- Safety protection devices: Equipped with multiple safety features including anti-fall mechanisms, overload protection, and emergency stop buttons to ensure the safety of both equipment and operators.

- Efficient power configuration: Powered by an AC380V industrial power source, the hydraulic system ensures stable and reliable operation even under frequent use.

- Optimized structural design: Key components are optimized through finite element analysis, achieving maximum structural strength while reducing weight and improving cost-effectiveness.

Selection Guide

When choosing the right hydraulic scissor lift for sale, consider the following key factors:

- Load requirement analysis: Select a suitable model based on the maximum daily load and keep a safety margin to ensure stable long-term operation.

- Working height determination: Define the required lifting stroke and final working height based on site layout and operational needs to meet actual application requirements.

- Installation space evaluation: Measure the installation area to ensure proper equipment placement and sufficient space for operation and maintenance.

- Usage frequency consideration: Choose industrial-grade models for high-frequency continuous operations to maintain long-term performance and reliability.

Maintenance and Care

To ensure that the scissor lift heavy duty platform maintains optimal performance, scientific maintenance is essential:

- Regular inspection and servicing: Establish a comprehensive inspection system covering hydraulic, electrical, and structural components to identify and address potential issues promptly.

- Hydraulic system maintenance: Replace hydraulic oil and filters periodically to keep the system clean and prevent damage from contamination.

- Structural part maintenance: Check fasteners and inspect for deformation or cracks in structural parts to maintain integrity and stability.

- Operator training: Provide professional training for operators to ensure they understand proper usage methods and basic troubleshooting.

As a key piece of modern industrial equipment, the hydraulic scissor lift platform directly affects production efficiency and operational safety. YG’s series stands out with superior manufacturing craftsmanship, reliable quality, and a complete service system, making it the preferred choice for industrial enterprises. With increasing industrial automation, such efficient and stable lifting platforms will continue to play an important role in enhancing productivity and competitiveness. Additionally, YG also offers articulated boom lifts, straight boom lifts, forklifts, and stackers—contact us anytime for more details!【WhatsApp/WeChat/Phone】+86 13837122632