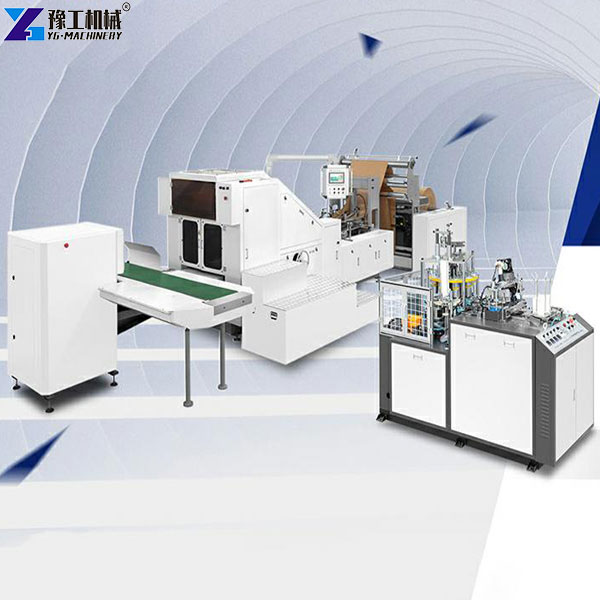

In the disposable tableware production field, the paper bowl machine stands out with its efficient and precise production capacity, becoming a crucial device for many enterprises to manufacture paper bowls. It can stably produce paper bowls that meet specifications, suitable for various scenarios like catering and food delivery. Want to know how this equipment helps reduce costs and increase efficiency? We are online 24 hours, providing product manuals and favorable quotes. Welcome to contact us!【WhatsApp/WeChat/Phone】+86 13837122632

Core Parameters of the Paper Bowl Machine

Product Parameters

The following are the main technical parameters of YG’s Middle Speed type, showcasing its performance:

| Name | Details |

| HS Code | 8441309000 |

| Model | -80 (with Finished Bowl Collect System) |

| Paper Bowl Size | A = 90mm – 140mm; B = 70mm – 110mm; C = 50mm – 105mm; D = 5mm – 11mm |

| Speed | 70 – 80pcs/min, can run stably for 20 hours |

| Raw Material | One-side or two-side PE coated paper (Single PE or Double PE coated paper) |

| Suitable Paper Weight | 170 – 350gsm |

| Voltage Supply | 380V 50hz 3 – phase (Please inform in advance if the voltage is different) |

| Working Air Source | Air pressure 0.6-0.8Mpa, 0.4m³/min (Users need to buy an air compressor by themselves) |

| General Power | 16KW |

| Net Weight | 3000kgs |

| Measurement (mm) | 2500×1300×1800 |

With these parameters, YG’s equipment can be customized to produce paper bowls of different specifications as needed, helping enterprises flexibly arrange their product lines and meet diverse market demands.

Paper Bowl Production Process

- Material Preparation: Purchase PE-coated paper. Choose single-side or double-side PE-coated paper according to the type of paper bowl, laying a solid foundation for subsequent production.

- Slitting: Use a slitting machine to cut the coated paper into rectangular rolls, which will be used as raw materials for the bowl walls and bottoms, precisely controlling the dimensions.

- Printing: A special printing machine prints patterns on the rectangular paper, giving the paper bowls a unique appearance and enhancing product recognition.

- Die-cutting: A roll die-cutting machine cuts out fan-shaped paper, preparing for the paper bowl forming and ensuring accurate shaping.

- Forming: Place the fan-shaped paper and roll paper into the paper bowl machine. The equipment automatically counts and folds, quickly making paper bowls with high efficiency and precision.

- Packaging: The finished paper bowls are bagged and boxed, completing the production cycle and facilitating storage and transportation.

Reasons to Choose YG’s Paper Bowl Machine

- Stable and Durable: Adopting a Geneva drive and a full-automatic lubrication system, the machine performs stably and has a longer service life, reducing equipment replacement costs. It is a reliable paper bowl making machine.

- Convenient and Efficient: Equipped with an automatic counting and cup-collecting function, it is easy to operate, reducing labor costs. As a bowl making machine, it has significant advantages for large-scale production.

- Low-noise and Long-Lasting: The independent knurling design reduces the operation stroke and noise, prolonging the equipment life and creating a quiet production environment.

- Intelligent Control: With PLC and touch-screen control, combined with imported electrical components, it has a high degree of automation, making production smarter. It is a high-quality disposable bowl making machine.

Finished Products:

Let YG Machinery Support Your Project!

YG’s bowl making machine, from the production process to equipment performance, demonstrates professionalism and efficiency in all aspects. Whether you care about the stable output of the paper bowl making machine or value the intelligent convenience of the disposable bowl making machine, we can meet your needs. Choosing YG means choosing worry-free production and reliable quality. Purchase with confidence and start a new journey in paper bowl production! Additionally, YG Machinery also sells high-quality equipment such as paper cup machines, toilet paper machines, tissue paper machines, and napkin paper machines.【WhatsApp/WeChat/Phone】+86 13837122632