In the rapidly developing packaging industry, the paper box making machine has become the core equipment for paper box processing with its automated production capabilities. It can accurately complete the forming of various paper boxes, meeting the packaging needs of food, gifts, electronics, and other fields, and significantly improving production efficiency. Want to know how this equipment can cut costs and boost efficiency for your business, and learn about the paper box making machine price? We are online 24 hours, providing detailed product manuals and exclusive discounts. Welcome to contact us for a quotation!【WhatsApp/WeChat/Phone】+86 13837122632

Core Parameters of the Paper Box Making Machine

The following are the key parameters of the equipment to help you accurately evaluate its adaptability:

| Parameter Item | Details |

| Box Length | 100 – 450mm |

| Box Angles | 5° – 40° |

| Box Width | 100 – 580/385mm |

| Edge banding height | 15 – 200mm |

| Occupancy of machine | 1.2m * 4m |

| Product speed | Max 180pcs/min |

| Bonding/Gluing device | Occupancy of the machine |

| Paper thickness | Max 1.5mm |

| Electrical requirement | 3kw/h |

| Air requirement | 6kg/cm² * 200L/min |

| Equipment size | 3.48m * 1.32m * 1.5m |

| G.W. | 1.5T |

| Package measurements | 3.55m * 1.35m * 1.7m (LWH) |

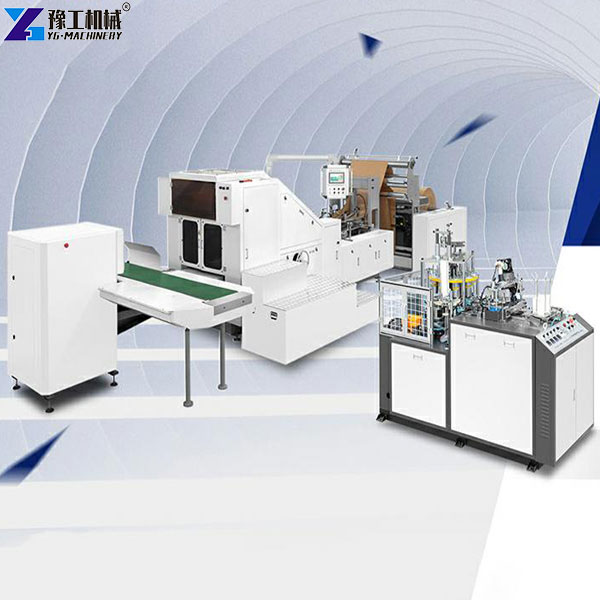

Components of the Paper Box Making Machine

It consists of a paper feeding system, a gluing system, a forming device, a paper box collector, and a paper box collection rack.

The paper feeding part adopts chain transmission, which runs smoothly and durably; each unit is designed independently, effectively reducing noise, reducing workload, and improving overall stability. The gluing system uses water-based adhesive, and the foam is evenly coated on the gluing position of the paper box through the roller, which is environmentally friendly and firmly bonded. The height of the forming mold is adjustable, and it can produce paper boxes of various specifications and shapes. For example, the flip-top hamburger boxes often produced by the burger box making machine can be accurately formed. The paper box collection rack can be adjusted by a handwheel, and the operation is simple and convenient.

Outstanding Features of the Paper Box Making Machine

- Flexible paper feeding: Adopts a mechanical rubber wheel paper feeding structure, which can convey paperboards of any size and specification without additional adjustment. The chain transmission design runs smoothly and is wear-resistant. The chain transmission of each unit is independent, reducing noise and workload. The transmission width can be adjusted by a lead screw, which is convenient and fast.

- Diverse forming: The height of the mold is adjustable, and it can produce various styles such as conical boxes and edge-clamped hamburger boxes, meeting the production needs of the hamburger box making machine and adapting to different packaging scenarios.

- Intelligent counting: Equipped with an automatic counter, which can set 100/200 group packages at a time, reducing the cost of manual statistics.

- Convenient operation: The size of the box collection rack is adjusted by a handwheel. When changing the mold, the frame can be opened, which is convenient for adjusting the position of the hook and reducing the operation difficulty.

Reliable Hamburger Box Making Machine Manufacturer

YG, as a professional and reliable packaging equipment manufacturer, all its equipment has been strictly tested from parameters to performance, and the quality is guaranteed. The equipment is not only efficient and stable but also can reduce the long-term production costs for enterprises. Choose YG now and start efficient production with confidence. Welcome to contact us at any time! In addition, YG Machinery also provides popular equipment such as paper plate machines, paper bowl machines, paper cup machines, and toilet paper machines.【WhatsApp/WeChat/Phone】+86 13837122632