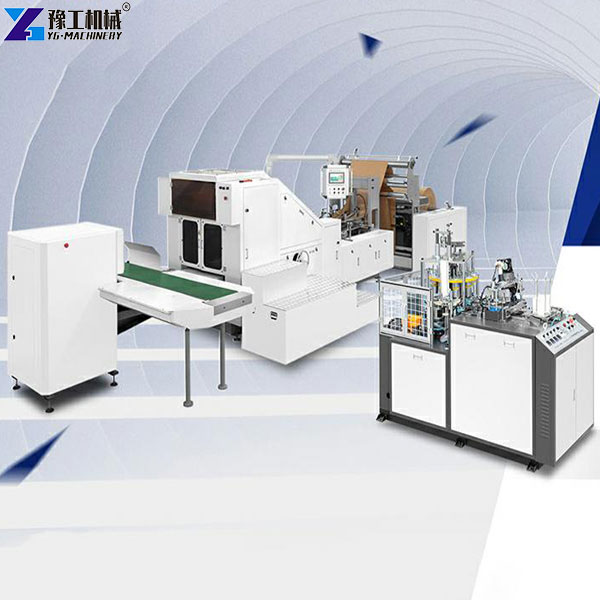

A paper napkin making machine is key for paper napkin producers to cut costs and boost efficiency. As market demands for quality, output, and customization grow, traditional manual production can’t meet large-scale, standardized needs. This core equipment of automatic lines integrates embossing, folding, counting, and cutting. Paired with single-head packaging machines, it enables full unmanned operation from base paper to finished packaging—solving production issues and boosting competitiveness. This article analyzes paper napkin machine parameters, advantages, and supporting equipment to guide selection. Welcome to inquire!【WhatsApp/WeChat/Phone】+86 13837122632

Core Equipment Parameters and Functions for Paper Napkin Production

1. Paper napkin making machine

As the “heart” equipment of the paper napkin production line, the paper napkin making machine realizes the automatic processing from base paper to finished paper napkins. Its core parameters and functions are as follows:

| Parameter Item | Details |

| Finished product size | 240*240mm (suitable for mainstream paper napkin specifications) |

| Base paper roll adaptation | ≤Φ1200 (compatible with multiple specifications of base paper, reducing roll change frequency) |

| Base paper core inner diameter | 75mm (standardized adaptation, ensuring feeding stability) |

| Production speed | 700 sheets/minute (high-efficiency output, meeting large-scale production) |

| Transmission system | 6-chain transmission (stable power, suitable for continuous production scenarios) |

| Counting system | Electronic counting (accurate quantity control, meeting packaging needs) |

| Power/Voltage | 4kw / 380v 3-phase 50hz (industrial-grade adaptation, reasonable energy consumption) |

| Equipment specifications (size/weight) | 3000*900*1600mm / 800KG (flexible layout, suitable for factories) |

Functional value: Its automated process (embossing, folding, counting, cutting) turns base paper rolls directly into square napkins—no extra napkin folding machine needed. Supports custom patterns (e.g., logos) for branding. Fully automated, it cuts labor and errors, saving costs and boosting efficiency.

2. Single-head packaging machine

As the downstream equipment connected to the napkin machine, the single-head packaging machine focuses on the automatic packaging of finished paper napkins. Its core parameters and functions are as follows:

| Parameter Item | Details |

| Packaging efficiency | 6-18 bags/minute (suitable for small-batch trial production to large-scale mass production) |

| Voltage/Air pressure | 220V 50HZ / 0.5MPA (suitable for conventional factory power supply and air supply) |

| Power | 1.2KW (low energy consumption, meeting cost reduction needs) |

| Range of packable sizes | L100-350*W100-350*H50-200MM (supporting customized adaptation) |

| Equipment specifications (size/weight) | 2500*1200*1200mm / 450KG (compact design, suitable for production line layout) |

Functional value: Handles bagging and sealing for soft tissue, paper napkins, square towels, etc. With auto-conveyor feeding and PLC control, it automates “feeding→bagging→sealing & cutting”. Easy parameter setup via LCD, precise temperature control (protects parts/consumables). Only manual bagging needed—boosts line efficiency by 30%+ and cuts labor reliance.

Core Competitive Advantages of Paper Napkin Making Machine

1. Automatic closed-loop: from “single-machine automation” to “production line collaboration”

- The napkin machine realizes the unmanned production of “base paper→finished paper napkins” (automatic counting, sorting, and pattern customization);

- The single-head packaging machine completes the automatic connection of “finished products→packaging” (the whole process of conveying, bagging, and sealing is controllable);

- Collaborative value: The full-process manual intervention rate is less than 10%, which not only ensures the consistency of product quality in each batch (such as folding accuracy and packaging tightness), but also increases the production line efficiency by more than 40%, adapting to large-scale order delivery.

2. Customized adaptation: from “standardization” to “flexible production”

- The napkin machine supports customized models (such as adding synchronous conveying and automatic paper feeding modules), and can also expand single-color/dual-color printing functions (needs customization to meet branding needs);

- The single-head packaging machine supports customized packaging sizes (L100-350W100-350H50-200MM for flexible adaptation);

- Adaptation value: A set of equipment covers the production of multiple products (soft 抽出,paper napkins, square towels, etc.) and specifications, helping enterprises use “flexible production lines” to meet the diverse needs of the market and reduce equipment idle rate.

3. Full-cycle cost optimization: from “procurement” to “operation and maintenance”

- Procurement stage: The equipment has stable performance (guaranteed by technologies such as 6-chain transmission and PLC control), low failure rate, reducing downtime losses;

- Operation and maintenance stage: Standardized parameters (such as 75mm base paper core inner diameter and conventional voltage adaptation) reduce the cost of replacing consumables and spare parts;

- Energy efficiency stage: The reasonable energy consumption of 4kw (paper napkin machine) + 1.2kw (packaging machine) is suitable for industrial power scenarios, which can save electricity expenses during long-term operation;

- Cost value: Through “low failure + low energy consumption + long service life”, it helps enterprises reduce comprehensive operating costs and improve the return on investment (ROI) of equipment.

Equipment Selection and Production Line Planning Suggestions

High-quality tissue napkin making machine and single-head packaging machine need to be evaluated from three dimensions: “production line collaboration, scenario adaptation, and long-term benefits”.

- Production line collaboration: Priority should be given to compatible equipment combinations (such as the parameter-adapted models in this article) to ensure the seamless connection of the “production-packaging” process, avoiding efficiency loss caused by conflicting equipment parameters (such as mismatched finished product sizes and conveying speeds);

- Scenario adaptation: For small-batch customized production, pay attention to the flexibility of the equipment (such as the convenience of adjusting the size of the packaging machine); for large-scale standardized production, focus on speed and stability (such as the continuous output capacity of 700 sheets/minute of the tissue napkin making machine);

- Long-term benefits: Pay attention to the durability and technical compatibility of the equipment. Priority is given to models with standardized components and easy maintenance to reduce later maintenance difficulty and spare parts procurement costs. At the same time, the equipment should have functional upgrade space (such as being able to access intelligent monitoring systems and expand high-speed production modules) to adapt to the higher future market demands for production capacity and intelligence.

Napkin Making Machine Price in YG Machinery

If you need to further analyze equipment parameters, customize adaptation schemes, or consult paper napkin machine price, please feel free to contact us. With in-depth industry understanding, YG Machinery can provide full-link support from “equipment selection→production line construction→operation and maintenance optimization”, helping enterprises build efficient and sustainable paper napkin manufacturing production lines. In addition, YG Machinery also provides high-quality equipment such as fully automatic toilet paper machines, paper cup machines, and paper bowl machines.