Tired of inefficient manual cutting and environment-polluting incineration? The modern rubber tire shredder offers a completely different solution. It enables automated continuous operation, processing tons of materials per hour. While reducing labor costs, it produces uniform rubber blocks, greatly improving the efficiency and value of subsequent deep processing.【WhatsApp/WeChat/Phone】+86 13837122632

Why Are Waste Tires Difficult to Dispose of?

- Complex Structure: Tires are composite materials made of rubber, steel wires, fiber cords and other components, which are hard to separate as a whole.

- High Elasticity: Rubber itself has high elasticity and toughness, making traditional crushing equipment either incompetent or inefficient.

- Bulky Volume: Whole tires occupy large space, leading to high transportation and storage costs. Direct landfilling or stacking will cause serious environmental and land resource problems.

- Pollution Risks: Improper disposal such as open-air stacking may cause fires and breed mosquitoes. Incineration will emit toxic gases.

Reuse Value of Shredded Tires

The rubber blocks processed by rubber tire shredder see a significant value increase and have a wide range of applications:

- Rubber Particles/Powder: Can be used in the production of plastic runways, artificial turf infill, modified asphalt, waterproof membranes, etc.

- Pyrolysis Oil Extraction: Rubber blocks are ideal raw materials for pyrolysis, which can extract pyrolysis oil, carbon black and steel wires to realize full resource utilization.

- Direct Utilization: Larger rubber blocks can be directly used as alternative fuels for cement kilns, or for engineering collision avoidance, playground floor buffering, etc.

- Reclaimed Rubber Production: Provide clean and uniform primary raw materials for manufacturing reclaimed rubber.

Limitations of Traditional Disposal Methods

- Landfilling: Occupies a large amount of land resources. Tires are hard to degrade naturally, and there are risks of fire and groundwater pollution. This method has been banned in many countries and regions.

- Incineration: Although it can recover some heat energy, it emits a large amount of toxic and harmful gases and dust such as dioxins and hydrogen sulfide, which seriously pollutes the atmosphere and fails to meet environmental protection requirements.

- Manual Cutting: Features extremely low efficiency and high labor intensity, with serious potential safety hazards. In addition, the produced rubber blocks vary in size, which cannot meet the demand of large-scale recycling and utilization.

How Can Rubber Tire Shredder Solve Problems of High Cost and Low Efficiency?

A professional rubber crusher machine is the key to cost reduction and efficiency improvement:

- Mechanized Continuous Operation: Replaces manual labor to realize automated processing from feeding to discharging, with a processing capacity of up to tons per hour.

- Robust Design for Tough Materials: Its specially-made alloy cutters and high-torque power system are designed to tear high-toughness rubber and cut internal steel wires, featuring durability and high efficiency.

- Pretreatment to Reduce Subsequent Costs: The shredded rubber blocks have high density and small volume, which greatly reduces the energy consumption and costs of transportation and subsequent processes (such as pulverization and pyrolysis).

- Intelligent Control: Modern tyre shredding machine is mostly equipped with PLC control system, with functions such as automatic overload protection and reverse unloading, ensuring safe and stable operation and reducing manual intervention.

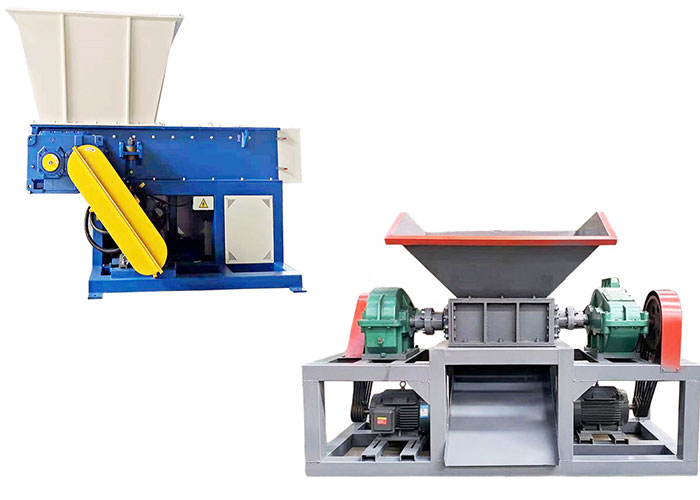

Single-shaft Vs. Dual-shaft Rubber Tire Shredder

- Single-shaft Shredder: Matches moving and fixed blades for strong shearing force and uniform discharge size. Ideal for fine-size requirements and single-type materials. Less suitable for extra-large or steel-wire-dense truck tires.

- Dual-shaft Shredder (Outstanding Advantages): Uses two counter-rotating shafts to shear, tear and pull materials. Delivers high torque via independent drives, perfect for heavy-duty tires like truck and engineering ones. Features automatic feeding and anti-winding design for efficient, stable operation — the mainstream choice for tire recycling.

Rubber Tire Shredder for Sale

The YG series tire shredder machine for sale we provide is a mature product based on dual-shaft shredding technology, specially designed for large-scale and high-efficiency waste tire recycling.

- Core Advantages: Sturdy and durable frame made of extra-thick plates; heavy-duty moving knives cast from special alloy steel with long service life; PLC intelligent control for safety and reliability; low rotation speed and high torque for stable operation and low noise.

- Wide Application: Not only suitable for various car tires and truck tires, but also applicable to processing mixed wastes such as plastics, wood and metals, realizing multi-purpose with one machine.

- Model Parameters: We offer a variety of models to meet different production capacity requirements. The specific parameters are as follows:

| Model | YG-600 | YG-1000 | YG-1200 | YG-1500 | YG-1800 |

| Knife size(mm) | Φ200*20 | Φ300*30 | Φ300*40 | Φ500*50 | Φ600*60 |

| Power (kW) | 11*2 | 37*2 | 45*2 | 75*2 | 90*2 |

| Capacity(t/h) | 0.3-0.5 | 1-1.2 | 2.5-3 | 3.8-4.5 | 6-7 |

| Knife quantity(pcs) | 30 | 26 | 30 | 38 | 45 |

| Machine size(m) | 2.6*1*2.1 | 3.4*1.25*2.2 | 3.8*1.25*2.2 | 4.4*1.5*2.5 | 5.3*2.1*2.8 |

Investing in a suitable rubber tire shredder is not only an entry ticket to the resource recycling industry, but also a wise move to fulfill social responsibilities and create economic value. From solving disposal problems to releasing resource value, an efficient piece of equipment is the most solid link in your entire recycling industry chain.

If you are looking for a reliable tyre shredding machine partner, please feel free to contact us for equipment selection solutions and detailed quotations tailored to your specific needs.【WhatsApp/WeChat/Phone】+86 13837122632