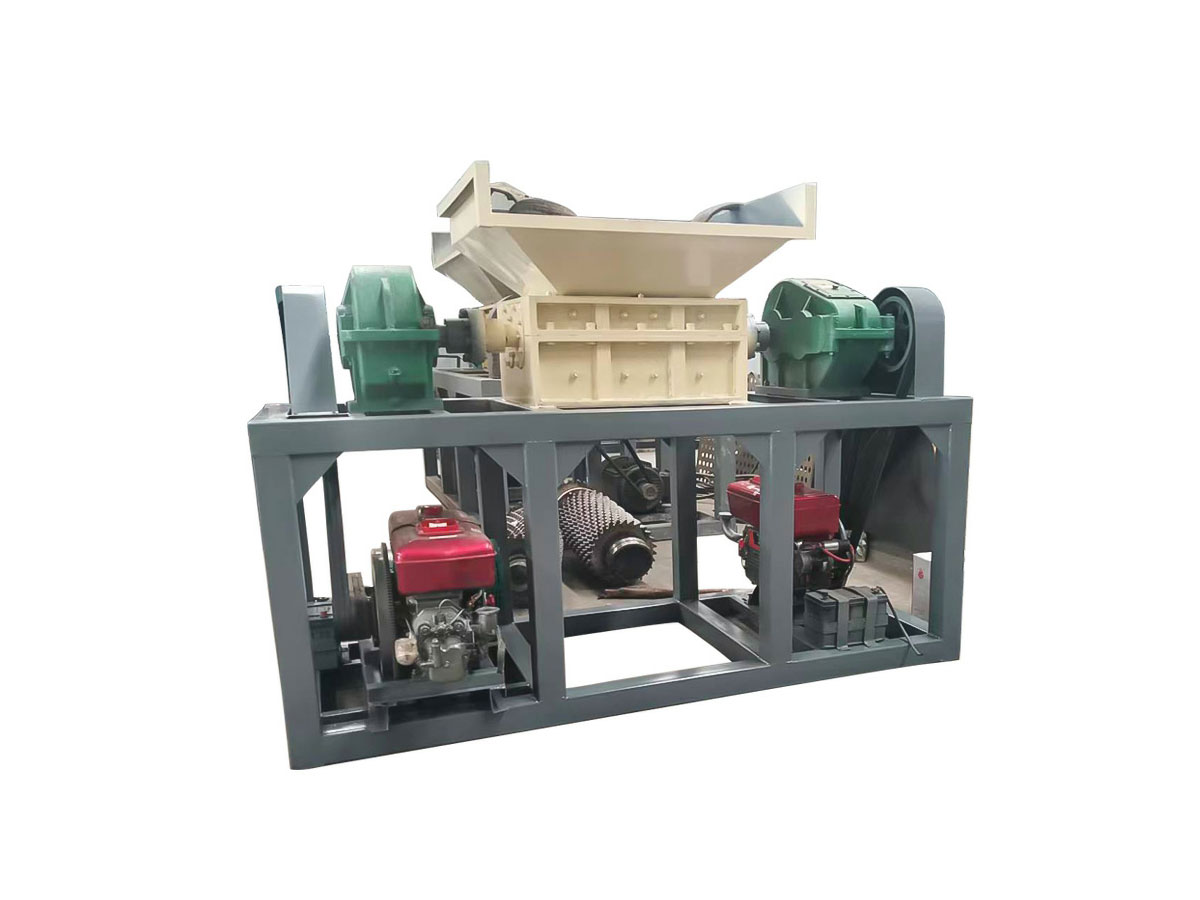

Faced with the pressure of disposing of over 15 tons of waste tires per day, a recycling center in Krakow, Poland, has introduced two sets of YG-1600 rubber tire shredder. The equipment operates stably and reliably, with energy consumption reduced by more than 30%, becoming a key factor in improving operational efficiency.【WhatsApp/WeChat/Phone】+86 13837122632

Rubber Shredding Machine Parameters

| Model | Power | Spindle Model | Capacity | Broken Size | Hopper Size | Dimensions(mm) |

| YG-600 | 4-15*2 kw | 18-20r/min | 2-3t/h | 3-10cm | 820*900mm | 2600*2000*1900 |

| YG-800 | 4-22*2kw | 18-35r/min | 3-5t/h | 3-10cm | 900*1000mm | 2800*2000*1900 |

| YG-1000 | 4-30*2kw | 18-35r/min | 5-8t/h | 3-10cm | 1200*1000mm | 3000*2000*1900 |

| YG-1200 | 4-37*2kw | 18-35r/min | 6-10t/h | 3-10cm | 1400*1000mm | 3200*2000*1900 |

| YG-1400 | 4-45*2kw | 14-35r/min | 8-12t/h | 3-10cm | 2000*2000mm | 4000*1700*2400 |

| YG-1600 | 4-75*2KW | 14-25r/min | 12-18t/h | 3-10cm | 2300*2000mm | 5000*3000*2400 |

| YG-1900 | 4-90*2kw | 14-25r/min | 16-22t/h | 3-10cm | 2300*2000mm | 6000*3500*2400 |

| YG-2200 | 4-132*2kw | 16-25r/min | 20-26t/h | 3-10cm | 2500*1800mm | 7000*4000*4500 |

| YG-2600 | 4-160*2kw | 16-25r/min | 25-60t/h | 3-10cm | 2425*1400mm | 8200*4000*4300 |

How Rubber Tire Shredder Solves Customers’ 3 Major Pain Points

When upgrading equipment, the Krakow recycling center mainly aimed to address the following operational pain points:

- Bottleneck of insufficient processing capacity: The original equipment had limited throughput, making it difficult to meet the growing volume of tire recycling, which resulted in low processing efficiency.

- High equipment maintenance costs: Frequent breakdowns and tool wear led to persistently high maintenance costs, affecting the normal production schedule.

- Energy consumption and environmental protection pressure: High energy consumption not only increased operational costs but also failed to meet Poland’s increasingly stringent environmental protection requirements.

Advantages of Rubber Tire Shredder

The YG-1600 rubber shredding machine has adopted a number of targeted technologies in its design:

- Optimized power and transmission system: It adopts a dual-motor drive configuration with a total power of 150KW, ensuring sufficient power when crushing all-steel radial tires. The main shaft is forged from special alloy steel with high torsional strength.

- Intelligent control system: Equipped with an advanced PLC control system, it has real-time monitoring, fault diagnosis and automatic protection functions. It will automatically reverse or shut down when overload is detected.

- Professional tool design: The heavy-duty tools are cast from special alloys, and undergo heat treatment and surface hardening. While maintaining high hardness, they also have toughness, effectively extending the service life.

Analysis of Operational Results

After months of continuous operation, the actual performance of the YG rubber tire shredding machine exceeded the customer’s expectations:

- Significant improvement in production efficiency: The processing capacity of a single set of equipment is stably maintained at 15-18 tons per day, and two sets of equipment fully meet the processing needs of the recycling center.

- Substantial reduction in operational costs: Energy consumption is reduced by more than 30%, and combined with the long-life tool design, the per-ton processing cost is significantly lowered.

- Verified equipment reliability: The mean time between failures is far longer than that of similar products, proving the excellent quality of this rubber tire shredder.

How to Select a Suitable Rubber Tire Shredding Machine

For customers considering browsing rubber shredder for sale information, the investment value can be evaluated from the following dimensions:

- Capacity matching analysis: Select the appropriate model according to the scale of your own business. The YG series offers a complete product line.

- Calculation of investment payback period: Considering factors such as equipment price, energy saving, reduced maintenance costs and increased production capacity, the investment can usually be recovered within 12-18 months.

- Long-term value evaluation: High-quality equipment can continuously create stable value within its 5-8 year service life, making it a fixed asset worthy of long-term investment.

Industry Outlook and Conclusion

This high-performance rubber tire shredder not only solves practical production problems but also injects new impetus into the development of the circular economy. With the continuous tightening of EU environmental protection policies, efficient, energy-saving and reliable processing equipment will become the industry standard. With its outstanding performance, YG equipment is helping more European enterprises achieve a win-win situation of economic and environmental benefits, and has become a reliable partner in promoting green development.【WhatsApp/WeChat/Phone】+86 13837122632

No responses yet