Rubber tire shredding machine is revolutionizing industrial and municipal waste processing, serving as a core tool to transform used tires, e-waste, metal scraps, and more into reusable resources. Designed for businesses of all sizes, it precisely meets diverse waste treatment needs with professional crushing capabilities. Looking for a reliable rubber shredding machine? Contact us now for quotes and customized solutions!

【WhatsApp/WeChat/Phone】+86 13837122632

Rubber Tire Shredder Machine In-depth Analysis

1. Flexible Product Parameter Design

| Model | Power | Spindle Model | Capacity | Broken Size | Hopper Size | Dimensions(mm) |

| YG-600 | 4-15*2 kw | 18-20r/min | 2-3t/h | 3-10cm | 820*900mm | 2600*2000*1900 |

| YG-800 | 4-22*2kw | 18-35r/min | 3-5t/h | 3-10cm | 900*1000mm | 2800*2000*1900 |

| YG-1000 | 4-30*2kw | 18-35r/min | 5-8t/h | 3-10cm | 1200*1000mm | 3000*2000*1900 |

| YG-1200 | 4-37*2kw | 18-35r/min | 6-10t/h | 3-10cm | 1400*1000mm | 3200*2000*1900 |

| YG-1400 | 4-45*2kw | 14-35r/min | 8-12t/h | 3-10cm | 2000*2000mm | 4000*1700*2400 |

| YG-1600 | 4-75*2KW | 14-25r/min | 12-18t/h | 3-10cm | 2300*2000mm | 5000*3000*2400 |

| YG-1900 | 4-90*2kw | 14-25r/min | 16-22t/h | 3-10cm | 2300*2000mm | 6000*3500*2400 |

| YG-2200 | 4-132*2kw | 16-25r/min | 20-26t/h | 3-10cm | 2500*1800mm | 7000*4000*4500 |

| YG-2600 | 4-160*2kw | 16-25r/min | 25-60t/h | 3-10cm | 2425*1400mm | 8200*4000*4300 |

2. Diverse Types

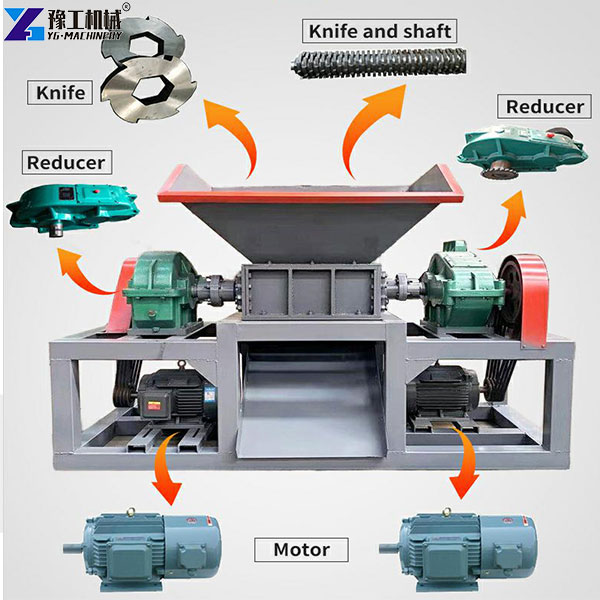

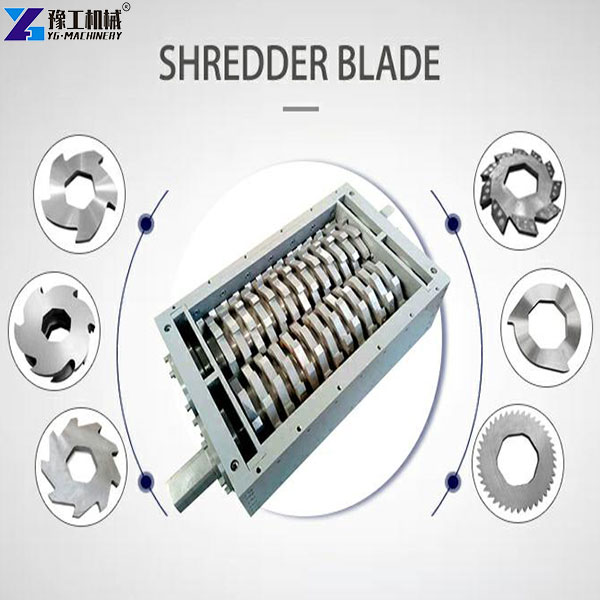

Rubber shredders rely on internal roller blades to cut, shred, and crush materials. Based on roller types, they are divided into three categories, each designed to meet specific crushing needs:

- Single-shaft Tire Shredder: Adopting an internal single-shaft roller design, it shreds tires through the rotational motion of the single shaft and the shearing action of the blades. This design gives it fine-processing capabilities, making it particularly suitable for handling smaller or thinner tires and scenarios requiring precise control over shredding particle size. It is an ideal choice for small tire shredder.

- Dual-shaft Tire Shredder: Equipped with two parallel rotating shafts with sharp blades, it quickly cuts tires into small pieces via intersecting blade motion. With strong crushing power and stability, it processes all tire sizes and types, serving as a common choice for tire recycling—particularly for primary crushing and preprocessing, and a mainstream model of rubber tire shredder machine.

- Quad-shaft Tire Shredder: Featuring four rotating shafts with multi-group blades, it achieves high-efficiency tire crushing through synchronized shear forces. Its superior performance boosts recycling efficiency for large-scale operations, making it a high-end solution for users prioritizing processing speed and quality, especially for heavy-duty crushing tasks.

3. Key Advantages of Rubber Tire Shredding Machine

- Wide Material Adaptability: Handles industrial scraps, plastic pipes, and dedicated tire crushing efficiently via professional roller designs, meeting preprocessing needs across industries.

- Durable Structure: Built with high-strength materials and special alloy steel rollers (processed through multiple stages), it ensures long-term stability, wear resistance, and reduced maintenance costs.

- Smart & Eco-friendly Operation: Advanced control systems enable automatic start/stop, reverse protection, and intelligent responses to anomalies. Low-noise operation and dust collection systems comply with modern environmental standards.

4. Versatile Application Scenarios of Rubber Shredding Machine

- Tire Recycling: Rapidly crushes used tires into rubber blocks for recycled rubber production, supporting circular economy goals. Suitable for both large recycling plants (using rubber tire shredder machine) and small stations (using small tire shredder).

- E-Manufacturing: Efficiently separates metals and plastics from e-waste like circuit boards, enabling resource reuse and reducing pollution.

- Wood Processing: Shreds wood scraps into biomass fuel chips, providing clean energy and secondary material utilization.

- Other Industries: Plays a key role in plastic recycling, metal processing, and municipal waste management. It crushes various materials—including rubber products—into optimal sizes for downstream recycling, aiding cost reduction and green production across sectors.

Rubber Tire Shredding Machine for Sustainability and Efficiency

YG Machinery’s rubber tire shredding machine undergoes strict quality control to ensure stable performance from R&D to production. With low energy consumption and pollution, it’s an ideal green solution for today’s environmental standards. No matter the waste type, our equipment delivers efficient, eco-friendly solutions. Contact us to explore details and customize your plan! YG also offers cost-effective equipment like metal shredder machine, bottle blowing machine, water bottle filling machine, pet bottle recycling line, plastic recycling line, round bottle labeling machine, sand blasting chamber, hanger type shot blasting machine, woven bag production line and more.

【WhatsApp/WeChat/Phone】+86 13837122632