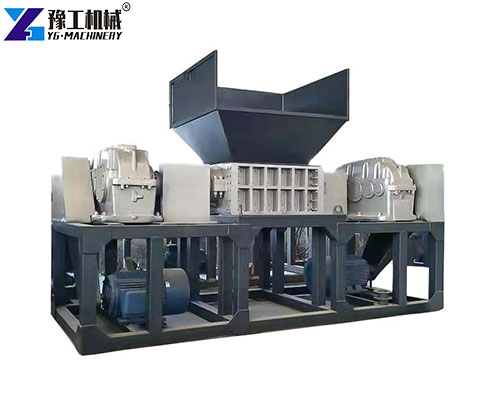

In factories where scrap piles up like mountains, every inch of space means cost. When traditional processing methods struggle to balance efficiency and environmental protection, a high-efficiency scrap metal crusher is transforming the situation. This innovative machine not only breaks down various types of metal waste into manageable sizes but also creates remarkable economic benefits for enterprises. Choosing a high-quality scrap metal shredder machine means gaining efficiency, low energy consumption, and a sustainable green solution—an ideal choice for modern businesses pursuing eco-friendly transformation. Feel free to contact us anytime for more product information!【WhatsApp/WeChat/Phone】+86 13837122632

Scrap Metal Crusher Parameters

| Model | YG-600 | YG-1000 | YG-1200 | YG-1500 | YG-1800 |

| Knife size(mm) | Φ200*20 | Φ300*30 | Φ300*40 | Φ500*50 | Φ600*60 |

| Power (kW) | 11*2 | 37*2 | 45*2 | 75*2 | 90*2 |

| Capacity(t/h) | 0.3-0.5 | 1-1.2 | 2.5-3 | 3.8-4.5 | 6-7 |

| Knife quantity(pcs) | 30 | 26 | 30 | 38 | 45 |

| Machine size(m) | 2.6*1*2.1 | 3.4*1.25*2.2 | 3.8*1.25*2.2 | 4.4*1.5*2.5 | 5.3*2.1*2.8 |

Scrap Metal Crusher Advantages

- Powerful Processing Capacity:

The scrap metal crusher adopts a combination frame made of extra-thick precision-machined plates, equipped with a large-angle hexagonal rotating shaft and a wide, durable feed hopper. It easily handles large materials such as bulky pieces, baskets, pipes, and sheets. - High-Efficiency Crushing System:

The machine features heavy-duty blades that significantly improve crushing performance. All blades are made of special alloy steel, ensuring strength, durability, and a long service life while effectively reducing replacement frequency and maintenance costs. - Intelligent Control System:

Equipped with a PLC control system, it enables fully automatic operation with start, stop, reverse, and overload auto-reverse functions. When the input material is excessive or oversized, the system automatically initiates forward/reverse rotation and shutdown to protect the machine. - Eco-Friendly Low-Noise Design:

The equipment operates at low speed with high torque and low noise. Dust emissions meet environmental protection standards, complying with modern industrial environmental requirements.

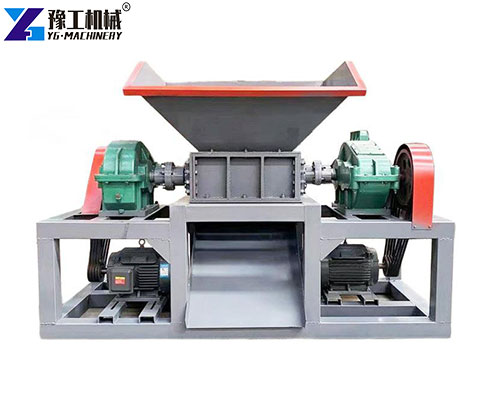

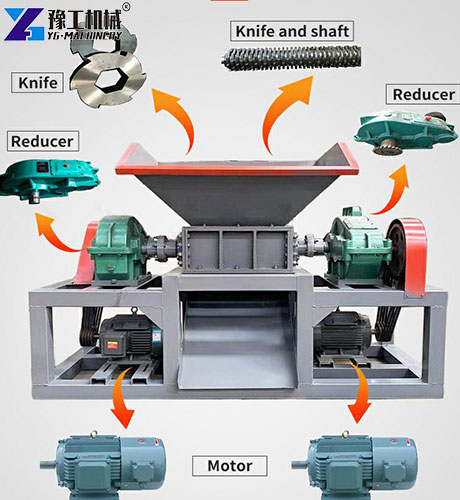

Scrap Metal Crusher Technical Features

- Dual-Shaft Independent Drive:

The scrap metal crusher adopts a dual-shaft independent drive design. During operation, materials are automatically fed and compressed, effectively improving overall working efficiency. - Unique Blade Structure:

The four-corner rotating blades work with a specially designed shaft to prevent winding or jamming during low-speed, high-torque operation, ensuring continuous and stable performance. - Modular Design:

The machine consists of modular components including blades, bearing boxes, frame, feeding system, motor system, and electrical control cabinet—making maintenance easier and component replacement faster.

Wide Application Fields

- Industrial Waste Treatment:

The scrap metal shredder machine plays a vital role in industrial waste recycling, efficiently processing metal scraps, discarded components, and industrial residues, providing reliable crushing solutions for the recycling industry. - E-Waste Recycling:

For waste generated by the electronics industry, it effectively separates and crushes metallic parts from old electronic products, improving resource reuse rates. - Municipal Waste Processing:

In urban waste management, this equipment handles metal containers, cans, and other waste, reducing volume and facilitating further processing. - Special Material Crushing:

It is also suitable for industries such as wood processing, plastic recycling, tire disposal, and papermaking, showcasing excellent versatility.

How to Choose the Right Equipment

When selecting a metal shredder for sale, several factors must be considered. First, choose the right model based on the material type and characteristics—models like YG-600 are suitable for small-scale processing, while YG-1800 fits large recycling enterprises. Second, ensure that the power and capacity meet production needs. Blade material and quantity are also crucial factors affecting performance. A high-quality metal shredder for sale should feature durable blades, an intelligent control system, and stable operating performance. It’s recommended to understand the machine’s specifications and the manufacturer’s after-sales support before purchasing.

A wise investment decision can yield remarkable returns. Choosing our metal shredder machine for sale means obtaining a highly efficient and reliable waste processing solution. Its outstanding crushing capability and smart control system help you tackle all metal waste challenges with ease. Meanwhile, the energy-saving, eco-friendly design ensures that you boost productivity while advancing sustainable development goals. Contact us today—let our metal shredder machine for sale create greater value for your business and open a new chapter in efficient scrap management!【WhatsApp/WeChat/Phone】+86 13837122632