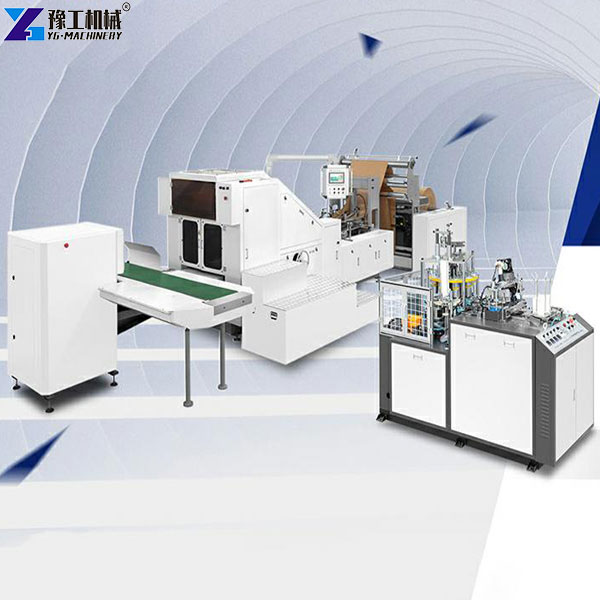

In today’s household paper industry, tissue paper—a daily necessity—has a growing market, drawing many businesses. YG Machinery’s tissue machine for sale uses mature automation to cover the entire process from base paper processing to packaging: it auto-feeds, folds via vacuum adsorption, and counts accurately, replacing tedious, error-prone manual work. Paired with a professional tissue paper packing machine (like double-head bagging heat-sealers), it forms an integrated “processing-packaging” line. Contact us for exclusive quotes and manuals!【WhatsApp/WeChat/Phone】+86 13837122632

Core Parameters Of Tissue Machine for Sale

The specific parameters are as follows:

| Model | YG-2L |

| Product Size(mm) | 180-200×80-430±2mm (Other sizes are available) |

| Paper Diameter(mm) | φ1100mm (Other sizes are available) |

| Paper Core Inner Dia | 76.2mm (Other sizes are available) |

| Speed | 0-100m/min |

| Controller | Frequency |

| Embossing Device | included |

| Embossing Roller End | included |

| Blank Lines | included |

| Cutting System | Pneumatic point cut |

| Vacuum System | 7.5kw |

| Pneumatic System | air compressor, at least the pressure 5kg/cm²Pa |

| Host Power | 3kw |

| Dimensions | 5500mm×1500mm×2300mm |

Take the YG-2L model: it processes cut paper into extractable facial tissue, with auto-feeding, vacuum-adsorbed interleaved folding, and auto-counting. Finished width is adjustable via a notched point cutter oran unnotched full cutter. It also has built-in decorative embossing or edge pressing (choose one), fitting various needs.

The YG-2L has a 560mm roller width, suitable for large base paper. Its vacuum adsorption and auto-counting ensure speed and accuracy; three tension adjusters guarantee folded product precision.

Supporting Packaging Equipment

The specific parameters of the double-head bagging and heat-sealing packaging machine are as follows:

| Parameter | Specification |

| Packing speed | 20 pack/min |

| Packing specifications | length: 90-210mm width: 90-100mm height: 40-100mm |

| Total power | 3.41KW |

| Motor power | 0.61KW |

| Air source pressure | 0.5MPa |

| Hot sealing bag material | CPP |

| Dimensions | 400025001200 mm |

| weight | 400kg |

Workers place the cut tissue paper on the conveyor belt of this packaging machine, which then conveys automatically. After two workers put bags on both ends, the tissue paper automatically enters the bags. It is then conveyed to complete heat-sealing on both sides, reducing manual contact and improving packaging tightness and efficiency.

Practical core values for your needs

(1) Energy consumption and cost control

Equipment (such as the YG-2L model) adopts an optimized power system, with low energy consumption during operation, which can reduce electricity expenses in the long run. Three tension adjustment devices reduce base paper waste, and when paired with the low-power design of tissue paper packing machine, the overall operating cost is controllable, suitable for small and medium-sized enterprises that focus on cost.

(2) Stability and failure rate

The equipment uses mature vacuum adsorption technology and precision transmission structure. The automatic counting function reduces manual errors, resulting in a low failure rate. It has passed strict tests to ensure stable continuous operation, reducing order delays caused by shutdowns for maintenance and helping enterprises produce as planned.

(3) Operation and maintenance support

YG Machinery has built a comprehensive operation and maintenance system. A detailed product manual is provided with the equipment, clearly marking operation guidelines and basic maintenance points. For complex problems, remote guidance is available, with technicians assisting in troubleshooting in real-time online; if remote solutions are not possible, technical personnel can be arranged for on-site service to inspect and debug.

Application Scenarios Of Tissue Manufacturing Machine

- For family workshops, there is no need for complex supporting facilities. Choosing small tissue paper making machine allows them to quickly start small-batch tissue production. The equipment is easy to operate, so even practitioners without large-scale production experience can quickly get started, meeting the needs of local small-scale retail or customized orders, such as providing small batches of tissue with exclusive logos for surrounding restaurants and convenience stores.

- Small and medium-sized factories can pair tissue machine for sale with the double head bagging line hot sealing packaging machine to form a semi-automatic production line. This not only increases the output per shift but also ensures stable product quality, easily supplying surrounding cities’ supermarkets, catering and other channels, covering the regional market, such as supplying standard packaged tissue products to chain supermarkets in prefecture-level cities.

- Large enterprises can realize mass continuous production of tissue paper by linking multiple tissue machine for sale with large-scale raw material procurement and warehousing systems. This production mode can meet the large-order needs of national chain brands and e-commerce platforms, radiating a broader market, such as providing tissue of uniform specifications for national chain catering brands.

Tissue Manufacturing Machine Manufacturer

Whether you are a start-up enterprise or expanding production capacity, YG Machinery can provide suitable solutions. If you need to know about equipment capacity, embossing patterns, or after-sales policies, please contact us. We will provide professional support for your tissue production business, promote efficient and stable production, and help your enterprise seize opportunities in the tissue market. In addition, YG Machinery also provides high-quality equipment such as toilet paper machines, napkin machines, and paper cup machines.【WhatsApp/WeChat/Phone】+86 13837122632