Dilemmas in Narrow-Channel and Heavy Shelf Installation

A large-scale e-commerce enterprise in Moscow plans to expand its warehouse. It needs to install 50 sets of heavy-duty steel shelves (each shelf is 6 meters high and weighs 300 kilograms, with a total weight exceeding 15 tons) in a narrow-channel area that is 300 meters long and only 2.5 meters wide.

The construction team initially tried to use forklifts for auxiliary installation but encountered difficulties:

- Channel Restriction: Forklifts have a large turning radius and are difficult to maneuver flexibly in the 2.5 – meter – wide channel. They collided with the existing light shelves on both sides of the channel many times, causing some shelves to be deformed.

- Insufficient Precision: The lifting and alignment precision of forklift arms is poor. It is difficult to accurately fix the shelves on the pre-embedded bases during installation, and the installation time for a single shelf exceeds 1 hour.

- Low Efficiency: The traditional method of manual cooperation with forklifts can only install 8 sets of shelves a day. At this rate, the warehouse expansion cannot be completed before the e-commerce peak season, which will affect goods storage and turnover.

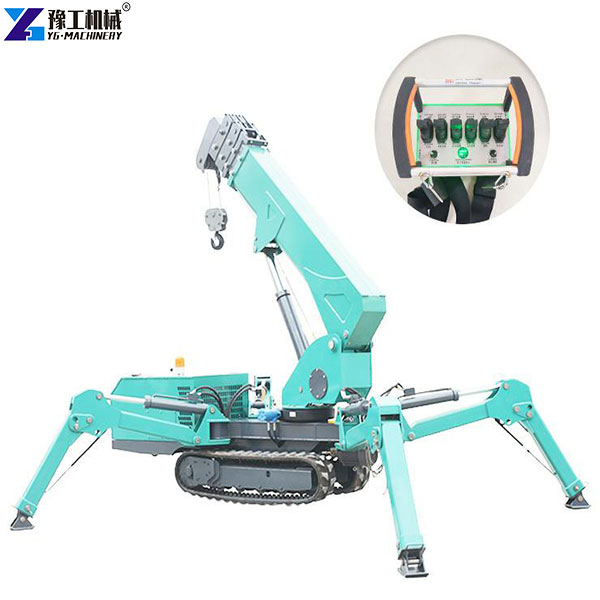

YG Machinery Tracked Mini Crane Precision Adaptation

Aiming at the pain points of e-commerce warehouse shelf installation, YG Machinery recommends a 5-ton mini tracked crawler crane (model YG-5). From equipment parameters to functional design, it matches the needs in all aspects:

(1) Core Parameter Table of the 5-ton Model (YG-5)

| Parameter Category | Specific Parameter Item | Value/Description |

| Basic Specification | Specification | 5t |

| Working Range | Maximum working radius | 14m×0.5t |

| Maximum above – ground head | 16.8m | |

| Winch Device | Hook Speed | 12m/min(4 rope) |

| Rope diameter | Φ11mm×80m | |

| Telescopic System | Boom Type | 5 – section boom, pentagonal structure |

| Boom Length/Time | 12.3m/54sec | |

| Luffing | Boom Angle/Time | 0°~78°/13sec |

| Slewing System | Slew Angle/Speed | 0 – 360°continuous/38sec |

| Traction System | Walking Way | Hydraulic motor drives |

| Walking Speed | 0 – 2.5km/h | |

| Grade Ability | (25°)36% | |

| Operating System | Operation type (Boom/outrigger) | Manual operation, manual walking(remote control option) |

| Operating characteristics | Manual operation, remote control | |

| Transport Parameters | L×W×H(mm) | 5000×1500×1900 |

| Total weight(kg) | 6200 |

(2) Customized Services and Value-added Configurations

- Protection Design: Anti-scratch rubber pads are added to the hooks to avoid paint damage during shelf lifting.

- Accessory Adaptation: Equipped with special shelf-lifting fixtures, which precisely match the lifting points on the top of the shelves. No additional manual binding is required, improving installation efficiency.

Practical Operation: Efficiency Increased by 3 Times, Precise Installation Wins Customer Praise

(1) Disassembly of the Installation Process

- Equipment Entry: Use the side door of the warehouse (3 meters wide) to quickly drive in with the diesel power mode. After entering the channel, switch to the electric mode, without noise or exhaust gas interfering with the office area.

- Shelf Lifting: Observe through the driving position and cooperate with remote control fine-tuning. Use the 14m working radius to directly lift the shelves from the storage area (5 meters away from the installation channel) to the installation point. The alignment time for a single shelf is less than 15 minutes.

- Fixing and Debugging: With the precise control of the hook, place the shelves stably on the pre-embedded bases. Quickly lock them through the fixtures and bases. Ensure the vertical deviation of the shelves is less than 2mm according to the parameters.

- Cyclic Operation: After completing the installation of one set of shelves, with the flexible movement speed of up to 0 – 2.5km/h, quickly turn the equipment and go to the next installation point for continuous operation without stutter.

(2) Customer Feedback (Andrei, Warehouse Operations Director)

“YG Machinery’s tracked mini crane totally solved our construction problems! We used to install 8 shelves a day. Now, with its efficient boom movement and precise hook control, we do 25—over 3x faster. It’s super accurate, keeping shelves stable. The electric mode in the warehouse doesn’t disturb the office at all. It helped us finish the warehouse expansion before the e-commerce peak. Awesome!”

Core Advantages of YG Machinery Mini Tracked Crawler Crane

(1) Hybrid (Oil-electric) and Multi-scenario Adaptation

For e-commerce warehouse scenarios that require quiet indoor operations and may involve outdoor equipment transfer, the oil-electric hybrid advantage of YG Machinery’s tracked mini crane is remarkable:

- Electric Mode: Meets the requirements of low noise and zero emissions in the indoor environment, suitable for the environment where the warehouse is adjacent to the office area.

- Diesel Mode: Provides strong power for outdoor equipment entry and long-distance shelf transfer, without being restricted by power sources.

(2) Precise Control and Efficiency Guarantee

The whole machine is designed with 3D modeling and finite element analysis. The boom has a 5-section pentagonal structure. Cooperating with the flexible operation mode (manual + remote control), it can achieve precise and efficient operations whether it is shelf installation in narrow channels or subsequent warehouse equipment maintenance and cargo lifting, reducing the interference of construction on warehouse operations.

(3) Full-process Service Support

- Pre-sales: Provide customized solutions according to the information provided by customers.

- In-sales: Arrange engineers to go to the Moscow site for guidance to ensure that the construction team quickly masters the operation points of the equipment.

- After-sales: Provide 24-hour remote technical support and timely respond to maintenance needs.

More Application Possibilities of YG Machinery Spider Crane

In addition to e-commerce warehouse shelf installation, YG Machinery’s tracked mini crane can also be adapted to these scenarios in the Russian logistics industry:

- Logistics Park Equipment Maintenance: In the narrow equipment channels of the logistics park, it can be used for lifting and maintenance of conveyors, sorting equipment, etc.

- Cold Chain Warehouse Cargo Handling: In low-temperature and narrow cold chain warehouses, use its precise control performance to lift large-scale frozen containers (low-temperature protection accessories can be adapted as needed, combined with the equipment’s power and other characteristics).

- Small-scale Logistics Building Construction: Such as the construction of small warehouses in logistics stations. Relying on the equipment’s compact size and lifting capacity, it can complete the lifting of building materials when the site is limited.

Call to Action: Exclusive Benefits for Russian Logistics Enterprises

- Limited-time Discount: Purchase a tracked mini crane for sale (model YG-5). Contact us to enjoy exclusive discounts, helping logistics enterprises reduce costs and increase efficiency. Acting now can also lock in the spot in advance, avoiding equipment shortages in the peak season!

- Free Benefits: Contact us to obtain the product manual of the mini spider crane for sale, which contains equipment parameters, operation guides, and maintenance points, helping you fully understand the equipment.

If you struggle with low efficiency and poor precision in narrow-space operations of Russian logistics warehouses, YG Machinery’s mini spider crane for sale breaks the deadlock. Contact us for spider crane price and exclusive logistics solutions. Boost warehouse efficiency to “soar” and handle business peaks calmly. YG Machinery also offers lifting platforms, forklifts, articulated boom lifts, etc.【WhatsApp/WeChat/Phone/Skype】+86 13837122632

No responses yet