The YG concrete pile cutter, as a professional excavator attachment, provides a new solution for concrete pile foundation treatment through its innovative modular design and hydraulic technology. This equipment not only effectively improves construction efficiency but also ensures the integrity of pile foundation quality, playing an important role in bridge projects and building foundations. In addition to the pile breaker machine, YG Machinery also offers milling machines, dual-cylinder hydraulic shears, rock saws, and car dismantling shears. Feel free to contact us anytime for more product details!【WhatsApp/WeChat/Phone】+86 13837122632

Concrete Pile Cutter Parameters

| Module Number | PCS | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Combination of the total weight | KG | 1600 | 2640 | 2970 | 3300 | 3630 | 3960 | 4290 | 4620 | 4950 | 5280 | 5610 | 5940 |

| Pile diameter range | mm | 400-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 1800-1970 | 1970-2200 | 2200-2360 | 2360-2500 |

| Hydraulic excavator | T | 20T-30T | 30T-40T | Hydraulic system/pump station | |||||||||

| Max.Thrust | 300KN | Max.Cylinder required | 20L/min | Machinery Tonnage | ≥20T | Location pinΦ35 | |||||||

| Max.Cylinder Trip | 300mm | Chisel diameter | 110mm | Singlemodule weight | 335KG | ||||||||

| Max.Cylinder Pressure | 300MPa | Max.Hoist Capacity | ≤500mm | Singlemodulesize | 1015*865*340mm | ||||||||

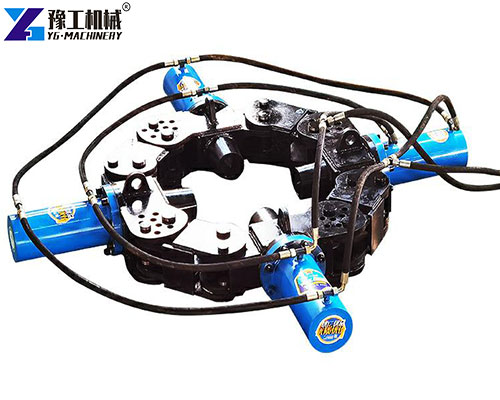

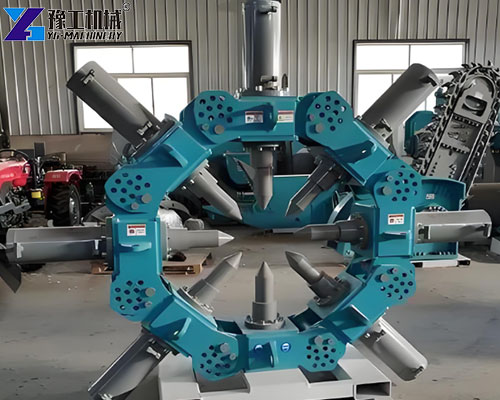

Innovative Modular Design of Concrete Pile Cutter

- Flexible combination configuration:

The equipment adopts standard modular units, with each module weighing only 335 kg. Modules can be freely combined according to pile diameter. With configurations ranging from 4 to 18 modules, it can handle pile diameters from 400 mm to 2500 mm, meeting diverse engineering needs. - Quick connection system:

The unique locating pin design makes module connection more convenient. Each module is uniformly sized at 1015865340 mm, which not only facilitates transportation and storage but also enables fast on-site assembly, significantly improving construction efficiency. - Wide equipment compatibility:

This innovative concrete pile cutter can be matched with 20–40 ton hydraulic excavators or connected to an independent hydraulic pump station, adapting to a variety of construction site conditions.

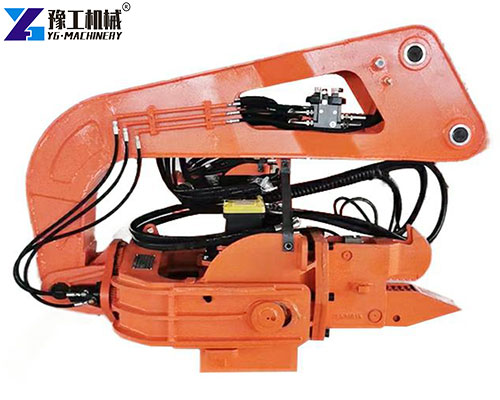

Professional Chisel Design of Pile Breaker Machine

- Anti-clogging structure:

The specially designed chisel effectively prevents soil from accumulating inside the guide flange, solving the common problem of steel bar jamming in traditional equipment and ensuring continuous operation. - Enhanced durability:

The chisel rod has a diameter of 110 mm and is made of high-quality alloy material, offering excellent wear and fracture resistance, which significantly extends the equipment’s service life. - Precision operation guarantee:

The precision guiding system ensures the chisel remains stable during the pile-breaking process without deviation, allowing the pile crusher machine to achieve precise and clean pile cutting results.

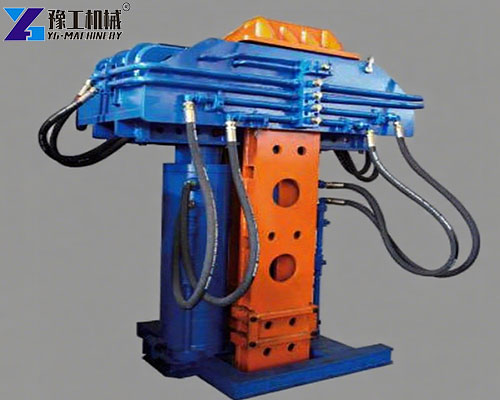

Intelligent Hydraulic System of Hydraulic Pile Breaker

- Intelligent pump station control:

A dedicated hydraulic intelligent pump station provides stable power with a simple, intuitive interface, achieving smart operation. The system offers a maximum thrust of 300 KN to ensure efficient pile breaking capability. - Accurate pressure adjustment:

With a maximum working pressure of 300 MPa, the hydraulic system features a precise control mechanism that automatically adjusts parameters according to different concrete strengths, achieving the best pile-breaking performance. - High energy efficiency:

The system requires only 20 L/min flow supply, ensuring both efficient operation and energy conservation, meeting modern construction’s environmental standards.

Wide Range of Applications

- Large-scale infrastructure projects:

In major infrastructure construction such as highways and railway bridges, the equipment can quickly and accurately complete pile head processing, ensuring engineering quality and progress. - Urban construction field:

Used in foundation treatment for residential and commercial buildings, this concrete pile cutter offers low noise and high efficiency, making it especially suitable for urban environments. - Challenging geological conditions:

The equipment maintains excellent performance across various ground conditions, and its modular design allows it to adapt to complex construction sites.

Operation and Maintenance Guide

- Simple operation system:

The user-friendly control interface allows operators to master the machine with minimal training. The intelligent monitoring system automatically tracks working conditions to ensure construction safety. - Routine maintenance essentials:

Regularly inspect the hydraulic system’s seals, clean the chisel area, and check wear on the module connection pins. These simple maintenance steps can effectively extend the machine’s lifespan. - Failure prevention measures:

Through scheduled maintenance and timely replacement of vulnerable parts, most malfunctions can be prevented. The equipment is designed for easy repair, with most components replaceable directly on site.

Overall, the pile crusher machine, with its innovative modular design, professional chisel structure, and intelligent hydraulic system, provides an efficient and reliable solution for modern pile foundation construction. Its superior performance and wide adaptability make it an essential piece of equipment in the infrastructure field. With continuous technological advancement, this cutting-edge pile-breaking device will play an even more significant role in future engineering projects.【WhatsApp/WeChat/Phone】+86 13837122632