In urban operation and maintenance, warehouse management, and small-scale projects, the safety and convenience of high-altitude operations are crucial. In recent years, mini scissor lift for sale has become a “new favorite” in small and medium-sized operation scenarios due to its characteristics of “small size but great function”. Whether it is equipment maintenance, shelf arrangement, or advertisement installation, this type of equipment can be quickly adapted, greatly reducing labor costs and operation risks. Contact us for an exclusive quote!【WhatsApp/WeChat/Phone】+86 13837122632

Product Parameters and Composition of Crawler-type Mini Scissor Lift for Sale

(I) Main Product Parameters of Popular Crawler-type Mini Electric Scissor Lift

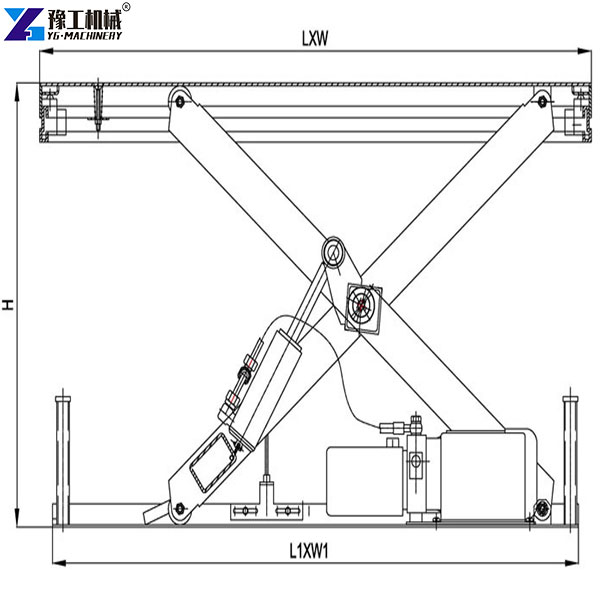

| Item | Unit | Parameter |

| Overall length of the machine | mm | 3211 |

| Overall width of the machine | mm | 1630 |

| Overall height of the machine (guardrail not folded) | mm | 2815 |

| Overall height of the machine (guardrail folded) | mm | 2260 |

| Rated working height | m | 15.75 |

| Maximum platform height | m | 13.75 |

| Maximum horizontal extension | m | 900 |

| Platform size | mm | 2640*1110 |

| Minimum turning radius | m | 0 |

| Minimum ground clearance | mm | 120 |

| Rated load mass | kg | 230 |

| Lifting/lowering speed of the working platform | s | 68/60sec |

| Lifting motor | V/KW | 48V/5KW |

| Travel motor | V/KW | 2*48v/5KW |

| Machine running speed (retracted) | km/h | 2.4 |

| Machine running speed (lifted) | – | 0 |

| Maximum climbing ability | – | 20% |

| Battery | V(ah) | 6V*8/300AH |

| Charger | A | 48V/25A |

(II) Product Composition of Crawler-type Mini Scissor Lift for Sale

Deep Dismantling! The Hard-core Composition of the mobile hydraulic lift platform, Professionals Should Check This

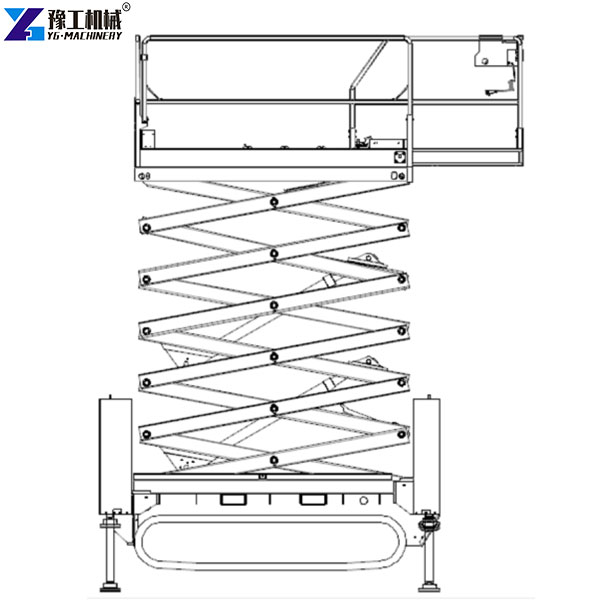

- Chassis Assembly: Made up of crawler assembly, welded crawler chassis, oil tank, power unit hydraulic parts, battery, and other hydraulic/electrical components. Motor-driven, with industrial rubber or iron crawlers for various environments. It has self-braking on ramps. The steering mechanism uses motor rotation to drive the crawler steering, giving an ultra-compact turning radius for narrow spaces.

- Boom Assembly: A scissor-arm mechanism is adopted, making the mechanism movement more flexible and improving work efficiency. At the same time, high-strength materials are used to reduce the weight of the entire scissor-arm assembly and enhance the stability of the machine. During the operation of the mini electric scissor lift, a stable boom is the basis for safe and efficient work.

- Electrical System: Uses CAN bus control. The chassis and platform have separate control panels; the platform has a display. They communicate via CAN bus to control machine actions, including chassis steering and travel. Safety features: tilt sensor restricts lifting/travel on dangerous ground; handle interlock switch prevents accidental operation; machine can’t travel when lifted, ensuring safety.

- Hydraulic System: Battery-driven pump powers the system. Uses U.S. Hydraforce components and electro-hydraulic proportional control for smooth actions, with high/low travel gears. Lifting cylinder has a buffer for smooth lowering; balance valve prevents automatic dropping if hoses break. Equipped with an emergency lowering valve for stable descent during failures or power loss, ensuring safety. This is key to mobile hydraulic lift platform reliability.

Product Features of Crawler-type Mini Scissor Lift for Sale

Why Crawler-type Mobile Platform Lifts Become the Market Focus! 6 Major Features Solve Operation Problems

- Foot-operated Extension Platform: Can be quickly spread to the operation point, saving preparation time and enabling the operation to start quickly.

- Foldable Fence: Reduces the volume of the whole machine, facilitating transportation and storage, and can be easily deployed in narrow sites.

- Small Turning Radius: Designed for narrow spaces, such as workshops, alleys, and other scenarios, it can shuttle flexibly without pressure.

- 30% Climbing Ability: Can climb slopes smoothly, coping with operation environments such as slopes and beside stairs, expanding the application range.

- Rotary Chassis: Facilitates maintenance. Maintenance personnel can easily access the components at the bottom of the equipment, reducing maintenance difficulty.

- Automatic Display of Fault Codes: Facilitates maintenance, quickly locates fault points when problems occur, and shortens downtime.

Choose the Right Equipment to Make High-altitude Operations Easier

Returning to the core needs, the value of crawler-type mobile platform lifts lies not only in “small size” but also in “precise matching”. It can not only meet the high-frequency use of daily maintenance but also adapt to the green operation trend through electrification upgrading. Whether you are a warehouse manager, an engineering team, or a property management team, choosing a mini platform lift that suits your own scenario can significantly improve operation efficiency and safety. The equipment of YG Machinery has passed strict inspection, and all components from the chassis to the hydraulic system are reliable! In addition, YG also has high-quality mechanical equipment such as spider cranes, forklifts, and curved-arm elevators. Contact us to learn more!【WhatsApp/WeChat/Phone】+86 13837122632