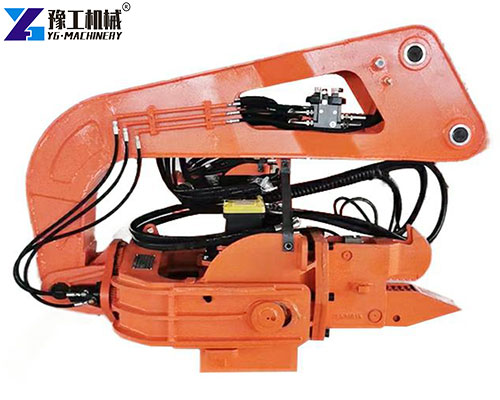

In modern engineering construction, efficient and flexible equipment is key to improving work efficiency. Excavator drum cutter, as an important excavator attachment, plays an irreplaceable role in handling various hard materials with its powerful milling capacity. It easily handles rock breaking in mining and foundation trimming in road construction, saving construction teams a lot of time and labor costs. If you want to know the specific quotation or need a product manual, feel free to contact us.【WhatsApp/WeChat/Phone】+86 13837122632

Core Parameters and Classification of Excavator Drum Cutter

(1) Parameter details of horizontal milling excavator

Our horizontal milling excavator, as a dedicated drum cutter attachment for excavators, has various models to match different tonnages of excavators. The core parameters of each model are as follows:

| Product Model | Applicable Excavator (T) | Weight (kg) | Milling Width (mm) | Milling Head Diameter (mm) | Number of Cutters | Recommended Speed (r/min) | Recommended Flow (L/min) | Max Pressure (Mpa) | Max Torque (NM) |

| HX – X1 | 6 – 9 | 450 | 420 | 340 | 40 | 95 | 80 | 35 | 4700 |

| HX – X2 | 10 – 18 | 550 | 650 | 450 | 56 | 85 | 120 | 35 | 7000 |

| HX – Z1 | 20 – 27 | 1100 | 850 | 560 | 64 | 78 | 220 | 35 | 14300 |

| HX – Z2 | 30 – 40 | 1250 | 950 | 660 | 64 | 75 | 320 | 35 | 23300 |

| HX – D | 45 – 60 | 2450 | 1150 | 850 | 60 | 55 | 360 | 35 | 40300 |

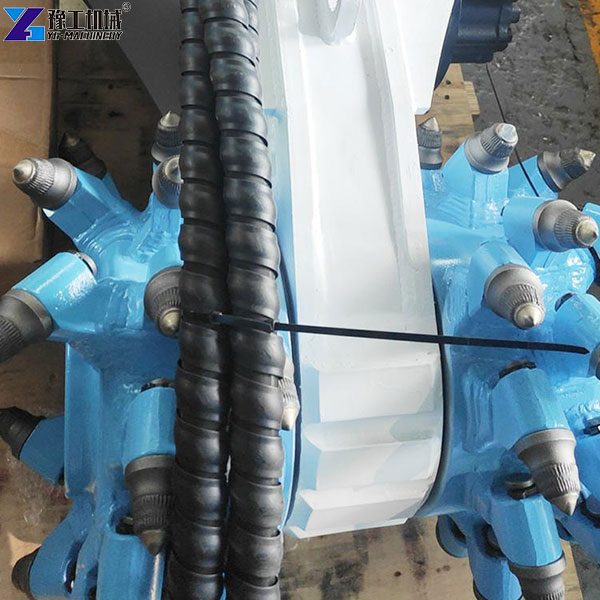

It can be installed on 6 – 60 ton excavators, widely used in ditch digging, tunnel trimming, building demolition and renovation, mining, road construction, etc. It can mill materials with compressive strength up to 90 MPa. Equipped with imported high-torque motors, imported bearing oil seals, and high-strength spur gear transmission, it works reliably even underwater. Its high-strength cutters are arranged based on years of experience, ensuring milling efficiency.

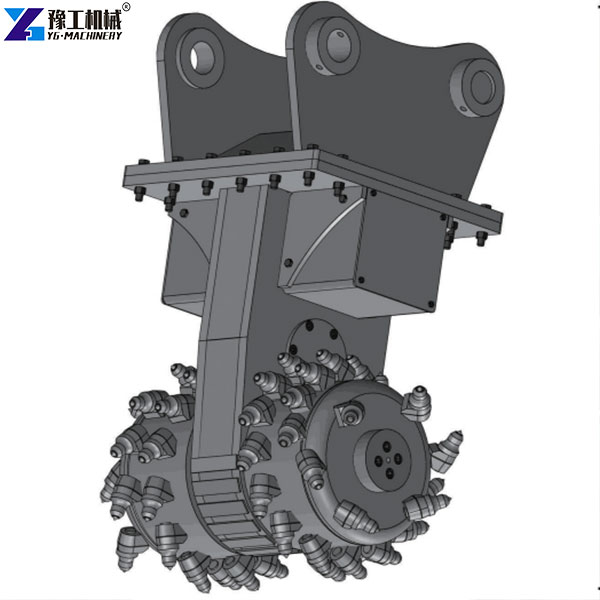

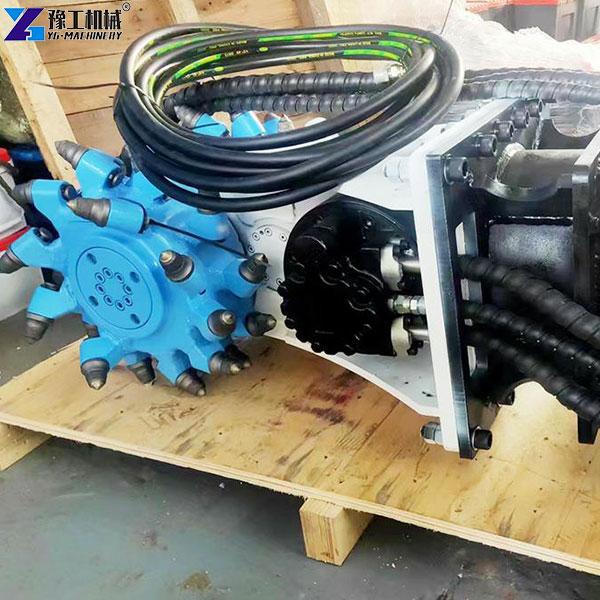

(2) Parameters and features of vertical milling excavator

This drum cutter attachment for excavator is mainly used in special trench digging, steel slag removal in the steel industry, pile head demolition, material mixing, and contour trimming. Our vertical milling excavators also have multiple models with the following parameters:

| Product Model | Applicable Excavator (T) | Weight (kg) | Milling Head Diameter (mm) | Number of Cutters | Recommended Speed (r/min) | Recommended Flow (L/min) | Max Pressure (Mpa) | Max Torque (NM) |

| ZX – 1 | 6 – 9 | 340 | 400 | 28 | 80 | 75 | 35 | 3780 |

| ZX – 2 | 10 – 18 | 480 | 450 | 32 | 80 | 120 | 35 | 7900 |

| ZX – 3 | 20 – 27 | 900 | 550 | 44 | 75 | 200 | 35 | 12700 |

| ZX – 4 | 30 – 40 | 1100 | 580 | 48 | 65 | 260 | 35 | 19600 |

Vertical milling excavators use imported hydraulic motors, high-torque reducers, and high-strength alloy cutters to ensure stable operation under high loads in harsh environments, and can also work underwater. In addition, connecting sleeves of different lengths can be customized to adapt to various construction conditions.

Outstanding Advantages of Excavator Drum Cutter

- High efficiency: Its cutters and power system quickly mill various materials, greatly accelerating construction progress.

- Flexibility: It adjusts flexibly for horizontal or vertical operations, adapting to different scenarios. The rotary drum cutter also has such flexibility, working well in complex conditions.

- Durability: High-quality imported components (e.g., motors, bearings) extend service life and reduce maintenance. The rotary drum cutter also performs well in durability, withstanding long-term high-intensity work.

- Safe construction: The equipment runs stably, ensuring worker safety and efficient progress. Small milled materials need no secondary processing and can be directly used for backfilling, saving costs.

Practical Cases of Excavator Drum Cutter

Case 1: Mining project in Sydney, Australia

- Project problem: Some rocks in a Sydney mine have high compressive strength. Traditional crushing equipment is inefficient, delaying the mining plan.

- Product use: The team used excavator drum cutter, which handles 90 MPa rocks. Its imported high-torque motor and strong cutters efficiently break rocks.

- Customer feedback: “This milling head for excavator is amazing! It finished days of work in two days, speeding up progress significantly. Worth it!”

Case 2: Road construction in Paris, France

- Project problem: A Paris road foundation is uneven. Traditional equipment fails to ensure trimming accuracy, affecting road quality.

- Product use: The team used drum cutter attachment for excavator to trim the foundation, adjusting angles precisely to ensure flatness.

- Customer feedback: “After using this drum cutter attachment for excavator, the foundation is perfectly flat, laying a solid base for road paving. We’re satisfied with its precision!”

Trustworthy Manufacturer

YG Machinery’s milling head for excavators is ideal for many construction teams due to its excellent performance, diverse types, and wide applicability. Our products undergo strict quality inspections, with meticulous design and production to ensure high quality. Whether in mining, road construction, or other fields, choosing YG Machinery makes construction more efficient and smooth. Buy with confidence and start your efficient construction journey! We also offer other excavator attachments: breakers, rippers, plate compactors, etc.【WhatsApp/WeChat/Phone】+86 13837122632