When an excavator arm is fitted with a “magnetic hand”, it changes more than just the way of handling materials. The excavator magnet attachment solutions provided by YG Machinery are designed to directly enhance the operational value and return on assets of a single piece of equipment. For enterprises engaged in scrap steel recycling, logistics and transportation, this translates to faster turnover, lower costs and clearer profit growth drivers, making every minute of operation more efficient.【WhatsApp/WeChat/Phone】+86 13837122632

Parameters of Excavator Magnet for Sale

| Model | Suitable Excavator ton | Weight kg | Power kW | Diameter mm | Working Flow lpm | Working Pressure bar |

| YGML02 | 4 – 6 | 1400 | 5 | 700 | 30 – 55 | 170 |

| YGML04 | 7 – 11 | 1500 | 8 | 800 | 50 – 100 | 180 |

| YGML06 | 12 – 16 | 1890 | 8 | 900 | 90 – 110 | 190 |

| YGML08 | 17 – 23 | 2000 | 10 | 1100 | 100 – 140 | 200 |

| YGML10 | 24 – 30 | 2200 | 10 | 1200 | 130 – 170 | 210 |

| YGML14 | 31 – 40 | 2500 | 15 | 1300 | 200 – 250 | 250 |

| YGML20 | 41 – 50 | 2800 | 15 | 1400 | 250 – 320 | 250 |

Customer Requirements

Australian customers aim to achieve further breakthroughs based on their existing modernized operations. Their core requirements focus on three aspects:

- Ultimate Efficiency and Continuous Operation Capability: The customers handle huge volumes of materials such as scrap steel and iron blocks. They require the attachment to enable quick adsorption and release, minimize equipment cycle time to the greatest extent, and support 24-hour continuous high-intensity operation.

- Excellent Safety in Complex Environments: Operational safety is of paramount importance in mines and crowded recycling yards. The customers need an attachment that can firmly grip materials to prevent falling from heights, while its structure must be strong enough to withstand collisions and wear.

- Versatile Equipment Adaptability: The customers expect a single attachment to handle multiple scenarios, ranging from lifting regular steel ingots at ports and terminals to cleaning up messy scrap steel at demolition sites. They require the excavator magnet for sale to not only deliver powerful performance but also feature outstanding working condition adaptability.

Excellent Performance of Excavator Magnet Attachment

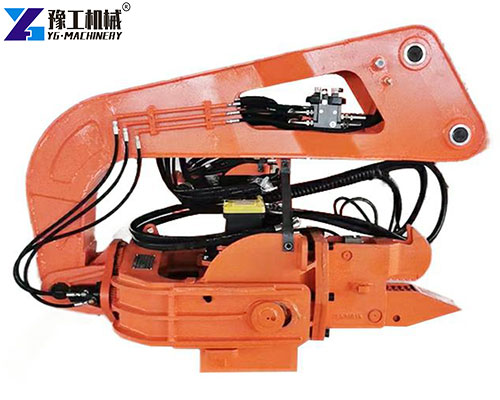

In practical applications, YG Machinery’s excavator magnet attachment fully addresses customer challenges with its innovative design, which is mainly reflected in the following aspects:

- High-efficiency Integration and Strong Power: The attachment adopts an advanced hydraulic drive system, directly utilizing the excavator’s own hydraulic power without the need for complicated external power supply. This design allows for plug-and-play functionality, and the strong magnetic force provided can easily handle various materials from light and thin scrap to heavy steel balls, improving the overall equipment utilization rate.

- Robust and Durable, Resistant to Wear: The core components are made of high-strength, corrosion-resistant Q345 manganese plate steel, ensuring that the product maintains long-term structural integrity and stable performance even in harsh environments such as Australian coastal areas or inland mines, significantly reducing the risk of downtime caused by equipment wear and tear.

- Intelligent and Reliable, Easy to Maintain: Adhering to the “semi-permanent” design concept, YG’s hydraulic excavator magnet optimizes the internal pipeline and sealing system, greatly extending the maintenance cycle and reducing daily maintenance workload. This enables customers to focus more energy on core production rather than equipment maintenance.

Customer Feedback on Excavator Magnet Attachment

After the equipment was put into use, YG Machinery’s excavator magnet attachment has won recognition from both operators and project managers. An equipment supervisor from a mine in Western Australia commented: “The adsorption force of this magnetic chuck exceeds expectations, and it is very stable when handling high-density iron blocks. More importantly, it has extremely high reliability and has never let us down in our high-intensity production schedule.”

Three Reasons Why YG Machinery is the Best Choice

In the highly competitive market, YG Machinery stands out thanks to its irreplaceable comprehensive advantages:

- Professional Manufacturer Gene Focused on Attachments: Like other leading enterprises in the industry, YG Machinery has a deep understanding of every detail of the coordinated operation between excavators and front-end attachments. This professionalism ensures that every hydraulic magnet is not just a simple accessory, but a performance enhancer that has undergone in-depth engineering tuning.

- Guarantee of High Quality and Global Certification: The company strictly complies with international quality standards, and its products have passed a number of authoritative certifications. From material selection to manufacturing processes, all are benchmarked against high-end industry standards, ensuring that every piece of equipment delivered to customers has excellent quality and safety.

- Comprehensive Pre-sales and After-sales Support System: YG Machinery not only offers a full range of models suitable for 4-ton to 50-ton excavators, but also provides perfect after-sales services. Customers can receive timely technical consultation, installation guidance and after-sales support, eliminating the worries of overseas procurement.

True cooperation starts with equipment delivery, but goes far beyond that. Through YG Machinery’s hydraulic excavator magnet, we look forward to working with industry partners around the world to create a more efficient and safer operational future. Every precise lifting contributes to building long-term trust and success for both parties. Partnering with YG Machinery is not just about purchasing an attachment, but about launching a project focused on cost reduction, efficiency improvement and sustainable leadership. We look forward to your inquiries and working together to write the next success story.【WhatsApp/WeChat/Phone】+86 13837122632

No responses yet