In rock and concrete processing projects, seeking a safe, efficient, and environmentally friendly solution has always been the core demand of the industry. The hydraulic rock splitter is exactly the modern equipment to meet this need. It can split hard rock in a precise and controlled way under conditions of no vibration, no noise, and no dust. If you are looking for a hydraulic rock splitter for sale, YG Machinery is a great choice. Feel free to contact us anytime for a free quote!【WhatsApp/WeChat/Phone】+86 13837122632

Hydraulic Rock Splitter for Sale Parameters

To help users better understand the performance of the equipment, here is a detailed parameter table of several common models:

| Model | YG-250 | YG-350 | YG-450 |

| Wedge Length(mm) | 250mm | 350mm | 450mm |

| Piston Stroke(mm) | 90/220mm | 90/220mm | 90/220mm |

| Drilling Depth(mm) | >500mm | >700mm | >900mm |

| Punching Diameter(mm) | 42mm | 46mm | 46mm |

| Crack Width(mm) | 10-20mm | 10-20mm | 10-20mm |

| Cleavage Time(s) | 10-15/s | 10-15/s | 10-15/s |

| Splitting Force(T) | 500t | 800t | 800t |

| Weight(kg) | 240kg | 250kg | 260kg |

From the table, it is clear that the equipment has strong performance in splitting force, operating speed, and drilling depth, which can meet the needs of projects of different scales.

Rock Splitting Machine’s Working Principle

The working method of the rock splitter machine is very straightforward. It generates high-pressure hydraulic oil through a hydraulic pump station, driving the wedges in the splitting head to expand outward, applying enormous splitting force inside the rock or concrete, so that cracks are formed and the material gradually separates. The entire process requires no blasting and does not cause damage to the surrounding environment.

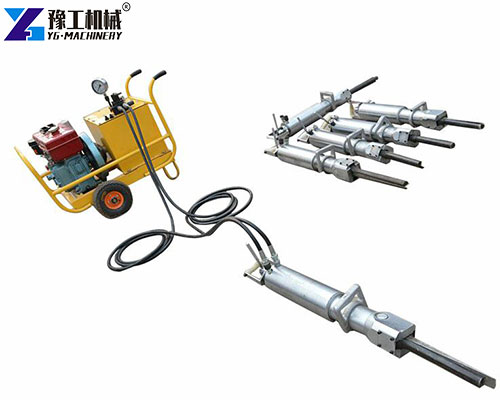

Main Components and Functions

- Hydraulic pump station: Provides power for the entire system, including electric and diesel models. The stability of the pump station directly determines the efficiency of the rock splitter machine.

- Splitting head: The core part of the equipment, composed of pistons and wedges, ensuring a strong splitting effect.

- Hydraulic pipeline: Used to transfer high-pressure hydraulic oil, requiring extremely high pressure resistance to avoid leakage.

- Control system: Provides pressure adjustment, start, and stop functions, making operation more convenient and reliable.

It is precisely the coordination of these components that allows the equipment to remain efficient and stable in various environments.

Equipment Advantages

- High efficiency: The splitting force of the equipment can reach hundreds of tons, and each operation takes only a few seconds, greatly shortening the construction period.

- Environmentally friendly construction: During operation, it produces no vibration, noise, or dust, fully meeting the requirements of modern green construction.

- Safe and reliable: It avoids the safety risks that blasting operations may bring, providing operators with a more secure working environment.

- Strong adaptability: Whether it is mine quarrying, tunnel construction, or city foundation excavation, the hydraulic rock splitter can work stably and adapt to complex environments.

Hydraulic Rock Splitter for Sale Application Scenarios

- Mine quarrying: Efficient quarrying of marble, granite, and other stone materials.

- Construction projects: Foundation excavation, concrete structure demolition, and old building renovation.

- Tunnels and underground works: Quickly splitting rocks in confined spaces to ensure construction safety and progress.

- Special environments: Areas where blasting cannot be used, such as city centers, around historical buildings, or high-risk zones.

These application scenarios demonstrate the importance of the rock splitting machine in modern engineering.

International Market Performance

At present, YG’s hydraulic rock splitter for sale has been successfully exported to Saudi Arabia, the UAE, and other Middle Eastern countries, Croatia in Europe, as well as Nigeria in Africa. Its efficiency, safety, and environmentally friendly features have been widely recognized by customers in different regions. With the growing global focus on green construction and sustainable development, the application prospects of this equipment will become even broader.

Reliable Supplier – YG

YG Machinery strictly controls quality during production, from raw material selection to precision machining, with multi-step inspections to ensure that every unit is durable and stable in performance. At the same time, we provide customers with comprehensive after-sales service, including installation guidance, operation training, and long-term maintenance support, so that after purchasing a rock splitting machine, you can use it without worry.【WhatsApp/WeChat/Phone】+86 13837122632