Pile Breaker, through innovative hydraulic technology, provides an efficient and precise method for cutting concrete piles. This equipment not only improves construction efficiency but also ensures the integrity of the rebar structure. It is widely used in engineering fields such as high-speed rail bridges and civil buildings. In addition to the concrete pile breaker, YG Machinery also offers other excavator attachments such as car dismantling shears, hydraulic shears, trommel screens, and milling machines. You are welcome to contact us anytime for more product information and exclusive quotations!【WhatsApp/WeChat/Phone】+86 13837122632

Pile Breaker Parameters

| Module Number | PCS | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Combination of the total weight | KG | 1600 | 2640 | 2970 | 3300 | 3630 | 3960 | 4290 | 4620 | 4950 | 5280 | 5610 | 5940 |

| Pile diameter range | mm | 400-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 1800-1970 | 1970-2200 | 2200-2360 | 2360-2500 |

| Hydraulic excavator | T | 20T-30T | 30T-40T | Hydraulic system/pump station | |||||||||

| Max.Thrust | 300KN | Max.Cylinder required | 20L/min | Machinery Tonnage | ≥20T | Location pinΦ35 | |||||||

| Max.Cylinder Trip | 300mm | Chisel diameter | 110mm | Singlemodule weight | 335KG | ||||||||

| Max.Cylinder Pressure | 300MPa | Max.Hoist Capacity | ≤500mm | Singlemodulesize | 1015*865*340mm | ||||||||

Working Principle of Pile Breaker

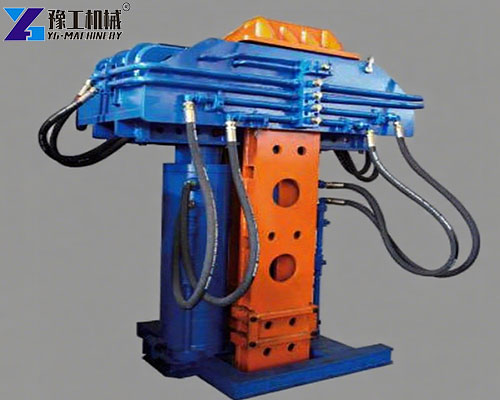

- Hydraulic Drive System: The equipment uses hydraulic cylinders to generate uniform radial pressure, driving chisels to squeeze the concrete pile body, causing it to fracture in a controlled manner. This mechanism avoids the randomness of impact breaking and ensures construction precision.

- Static Pressure Crushing Process: Unlike traditional methods, the pile breaker adopts a static pressure approach, gradually applying pressure to create internal cracks in the concrete, thereby achieving complete pile cutting.

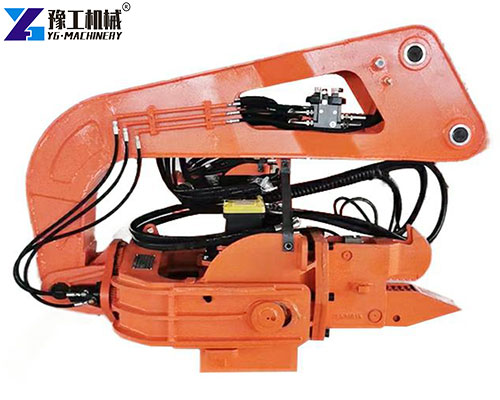

- Multi-Machine Compatibility: The equipment supports multiple construction machines such as excavators and cranes. It can be powered by a hydraulic pump station or a main power source, allowing flexible operation. This design enables the hydraulic pile breaker to operate stably even in complex job sites.

Advantages of Hydraulic Pile Breaker

- Efficient Construction and Cost Saving: The equipment is easy to operate and requires fewer personnel, significantly reducing labor and maintenance costs. Meanwhile, its fast pile-cutting ability shortens the construction cycle and improves overall efficiency.

- Safety and Environmental Protection: The remote control system keeps operators away from the work area, making it suitable for complex terrains. The fully hydraulic drive ensures low noise and zero dust emissions, meeting green construction standards.

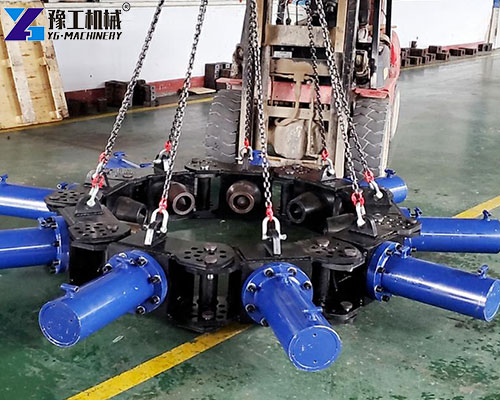

- Multi-Function and Long Service Life: The modular design supports both round and square pile breaking, realizing multiple functions in one machine. High-quality materials and optimized structure extend service life and reduce replacement frequency.

Application Scenarios and Operation Guide

- Diversified Engineering Applications: From high-speed rail bridges to civil buildings, the equipment can handle piles with diameters ranging from 400mm to 2500mm. The flexible module combination allows easy adjustment — for example, in large-scale projects, the number of modules can be increased to handle larger pile diameters.

- Simple Operation Process: Users only need to connect the hydraulic source, install the modules, and start the system. The concrete pile cutting machine automatically completes the breaking process. Its intuitive interface reduces training requirements, allowing even beginners to operate it easily.

- Strong Adaptability: The telescopic lifting chain design allows stable operation on uneven terrain, while its compact structure makes transportation and storage more convenient, improving on-site adaptability.

Maintenance and Care Tips

- Daily Inspection Items: These include checking hydraulic oil levels, chisel wear, and tightening of connection parts. Simple maintenance can prevent failures and extend the service life of the equipment.

- Module Maintenance Recommendations: Each module is easy to disassemble and clean. During storage, it should be kept away from corrosive environments. The hydraulic system of the hydraulic pile breaker should have its oil replaced regularly to maintain optimal performance.

Why Choose YG Machinery

YG Machinery not only provides a stable-performance concrete pile cutting machine but also offers comprehensive technical support, after-sales service, and spare parts supply. With strict quality control and a complete supply system, YG Machinery’s concrete pile breaker has been exported to many countries and regions, earning wide recognition from customers. Choosing YG Machinery means choosing a more efficient, safer, and more reliable pile foundation construction solution. Contact us anytime for more product details!【WhatsApp/WeChat/Phone】+86 13837122632