In the new residential building project in Santo Domingo, Dominican Republic, the construction team once faced an efficiency problem: “after mortar spraying, manual troweling and smoothing of each wall surface was required, and 5 workers could only complete a maximum of 300 square meters of walls in one day”. This dilemma was solved when YG’s “Mortar Sprayer Machine + Auto Wall Plastering Machine” was introduced.【WhatsApp/WeChat/Phone】+86 13837122632

Specifications of Mortar Spraying Machine:

| Type | Electric | Diesel |

| Output | 3m³/h | 4m³/h |

| Power | 220v-380v/7.5kw | Diesel |

| Pressure | 3Mpa | 3Mpa |

| Conveying tube | 32mm | 32mm |

| Max. Aggregate size | ≤8mm | ≤8mm |

| Hopper volume | 80L | 80L |

| Air consumption | 0.3m³/min | 0.3m³/min |

| Weight | 320kg | 320kg |

| Applicable material proportion | 1:1:3 | |

| Conveying distance | Horizontal:50m Vertical:30m | Horizontal:50m Vertical:30m |

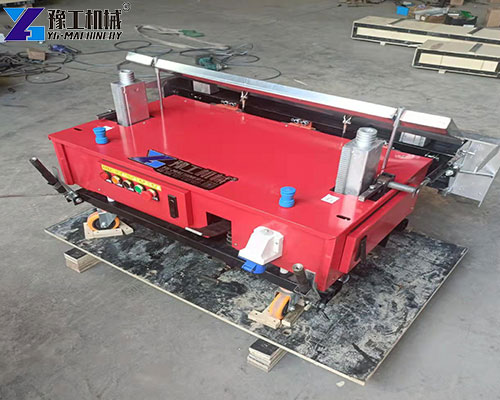

Specifications of Auto Wall Plastering Machine:

| Model | YG-800 | YG-1000 |

| Plastering height | Below 4 meters | Below 5 meters |

| Weight | 270 kg | 290 kg |

| Plastering thickness | 2~30 mm | 2~30 mm |

| Power | 1.5 KW | 1.5 KW |

| Plastering efficiency | 500 CBM/8H | 550 CBM/8H |

| Voltage | 220 v/380 v optional | 220 v/380 v optional |

Project Background

The construction schedule of this residential building project was tight, and the traditional pure manual operation mode had become the biggest constraint to the project progress. Its pain points were concentrated in three aspects:

There was a ceiling on manual efficiency—skilled workers were in short supply, labor intensity was high, and progress was difficult to control;

Comprehensive costs remained high—high labor costs and uncontrollable material waste continued to erode project profits;

Quality depended on individual craftsmanship—problems such as hollowing on walls and poor flatness occurred frequently, leading to high rework risks. The project party was in urgent need of an innovative solution that could break through the triple barriers of efficiency, cost, and quality simultaneously.

Solution: Mortar Sprayer Machine and Auto Wall Plastering Machine

YG provides an interlocking mechanized construction system, whose excellence lies in the seamless collaboration between the two machines and their respective technical advantages:

- Efficient spraying layer: The continuous and stable Mortar Spraying Machine is a pioneer in efficiency. It adopts screw pumping technology to ensure continuous mortar delivery without pulses, achieving uniform spraying and strong adhesion. Its horizontal conveying distance can reach 50 meters, and the equipment can be placed fixed, easily covering the entire floor’s working surface, thus freeing workers from heavy repetitive labor.

- Intelligent smoothing layer: Following closely is the automatic wall plastering machine. This equipment realizes quick positioning in 10 seconds through a hydraulic system, and uses a unique vibrating scraper technology to complete compaction, leveling, and smoothing in one go during the automatic upward movement. Its intelligent control system can ensure extremely high verticality and flatness, and the construction quality is far beyond manual work—just as similar equipment in the market pursues, it can replace a large number of craftsmen and save a large amount of materials.

Application Effects and Customer Feedback

After the combined solution was put into application, its effects were immediate. The most direct comparison is: under the manual mode, 5 workers completing 300 square meters a day was the limit; while with the YG mortar sprayer machine combination, 2 workers completing 500 square meters a day has become a stable output. The project manager calculated an economic account: in addition to the direct reduction of nearly 50% in labor costs, the extremely low amount of fallen mortar in mechanical operation also enabled a material saving rate of about 15%-20%. In addition, hollowing and cracking on the walls were almost eliminated, and the one-time acceptance pass rate was close to 100%, completely avoiding potential costs and disputes caused by later maintenance.

“This equipment combination has completely changed our operation logic,” said the on-site supervisor. “It is not just a mortar sprayer machine and an auto wall plastering machine, but a standardized production process that guarantees the construction period, quality, and profits. This has greatly increased our confidence in undertaking subsequent projects.”

Who Are the Best Users of This Combined Solution?

YG’s mortar spraying machine and automatic wall plastering machine combination accurately targets user groups in the construction market who are eager to pursue modernization:

- Real estate development and construction enterprises: Suitable for batch-constructed residential communities and apartment buildings, with a strong demand for accelerating capital withdrawal and building brand reputation.

- Professional exterior wall and decoration engineering companies: Enterprises focusing on internal and external wall renovation and integrated thermal insulation and decoration construction—this combination can greatly enhance their professional capabilities and competitiveness in undertaking projects.

- Small and medium-sized construction contractors: When facing multiple small and medium-sized projects, this set of flexible and efficient equipment can be quickly transferred to different sites, and it is a key investment for realizing business upgrading and surpassing peers.

Choose YG

Stop waiting and take action now! Choosing YG’s mortar sprayer machine and auto wall plastering machine combination is not just buying equipment, but purchasing a “profit accelerator” for your construction business. It promises not only several times the efficiency improvement and nearly half the cost savings, but also a competitive guarantee for ensuring the construction period and winning with certainty. Contact us now to get an exclusive plan, and let your next project become the starting point for widening the gap with competitors and leading the industry.【WhatsApp/WeChat/Phone】+86 13837122632

No responses yet