Still frequently changing equipment for processing different wire types? Worried about poor processing results for steel bars (under 14mm), stainless steel wires, aluminum wires, or plastic-coated steel wires? This rebar straightener solves these problems. It handles straightening and cutting of steel bars under 14mm, with customizable cutting lengths. It efficiently processes various wires, ensuring neat cuts, small errors, and stable performance. Contact us for quotes and product manuals.【WhatsApp/WeChat/Phone】+86 13837122632

Product Parameters of Bar Straightener

Here are the detailed parameters of different bar straightener models for diverse needs:

| Model | YGT 4-14 | YGT 5-16 |

| Diameter adjustment range | 4-14mm ( Ⅲ grade steel) | 5-16mm ( Ⅲ grade steel) |

| Wire pulling speed | 50m/min | 50m/min |

| Traction motor power | 2.2kw-6 | 2.2kw-6 |

| Modulation motor power | 7.5kw-4 | 15kw-4 |

| Cut off motor power | 5.5kw | 5.5kw-4 |

| Cutting error | ±0.5-1cm | ±0.5-1cm |

| Wire length | 800-9000mm (can be lengthened) | 800-9000mm (can be lengthened) |

| straightening degree | ±2 mm/m | ±2 mm/m |

| Weight | 1500kg | 1500kg |

| Size | 2800*650*1200mm | 3300*650*1300mm |

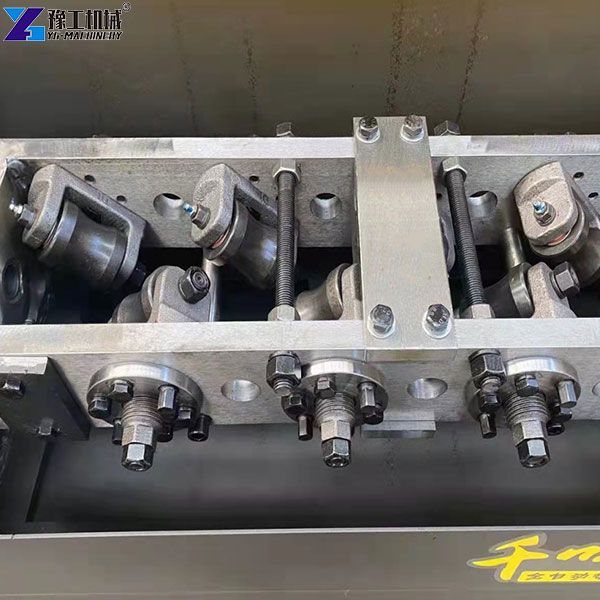

Its direct-pressure meter-counting system, with 9kw-11kw + flower-pattern wheels made of chrome 12 molybdenum vanadium, is flexible, adjustable, and accurate for precise length control.

Working Principle of Rebar Straightener

The equipment’s workflow is seamless, with components working together for efficient straightening and cutting:

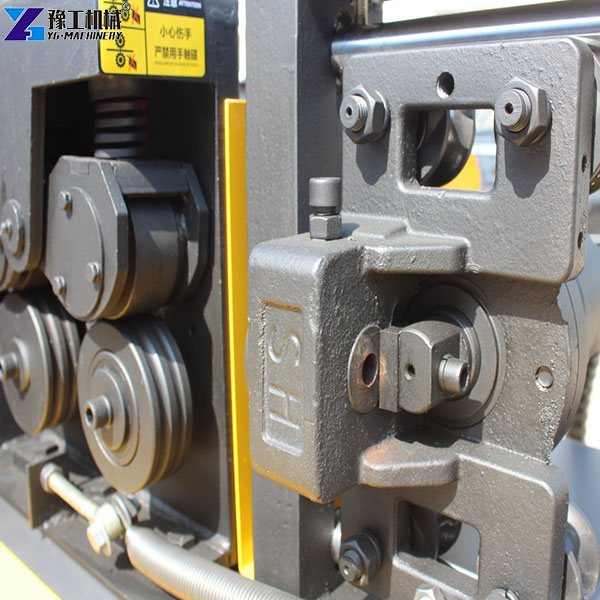

1. Straightening Mechanism and Power Transmission: The straightening mechanism consists of straightening rollers, a straightening press, and bearings at both ends of the machine body. Power comes from the motor under the frame, driving the straightening shaft to rotate at high speed via a V-belt, providing the power base for steel bar straightening.

2. Straightening and Rust Removal: The motor accelerates via belt drive, making the straightening roller run at high speed. When the steel bar passes through, it gets straightened, and rust on the surface is removed, making it cleaner for subsequent processing.

3. Feeding and Cutting Actions: The feeding mechanism consists of two pressure wheels that operate synchronously. The motor drives two conveying rollers through another set of deceleration belt drives and a gear reduction box. On one hand, it pulls the steel bar to continuously convey forward; on the other hand, it drives the crank wheel to make the hammer head move up and down. When the steel bar reaches the preset length, the hammer head strikes the tool rest to cut off the steel bar; after the steel bar falls into the material rack, the tool rest resets by means of a spring, preparing for the next processing. In this way, continuous straightening and cutting operations are realized.

Outstanding Performance Advantages of Bar Straightening Machine

1. High-Quality Oil Pump: Equipped with a high-quality oil pump, it has fast oil return, long service life, ensuring stable operation, reducing downtime, and improving efficiency.

2. Four-Wheel Feed Inlet: The four-wheel design makes steel bar insertion easy with low resistance, easing feeding and avoiding process delays.

3. Upgraded Solenoid Valve: The upgraded valve prevents internal and external leaks, controls oil precisely, ensuring stable hydraulic pressure for accurate straightening and cutting.

4. Thickened Straightening Frame: The integrally welded, thickened frame has high strength and rigidity, ensuring good straightening results and long-term stable use.

Diverse Application Scenarios of Rebar Straightener

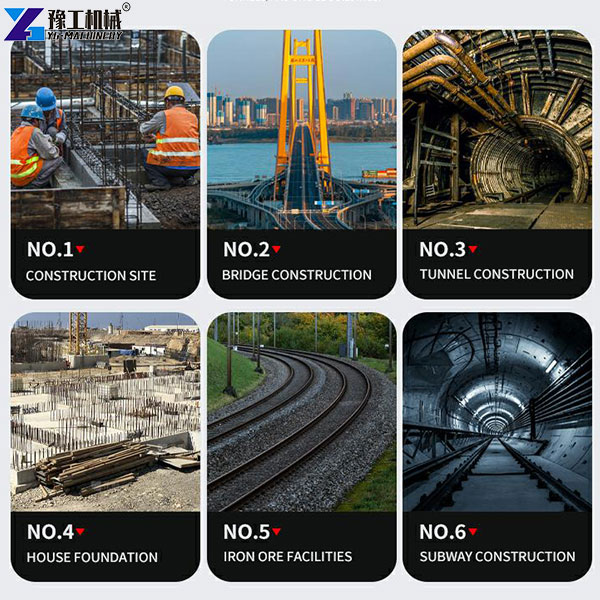

With excellent performance, the steel bar straightening machine suits various processing scenarios:

1. Steel Bar Processing in Construction: In construction projects, it straightens and cuts steel bars for beams, slabs, and columns, providing qualified materials for accurate and firm steel frameworks.

2. Steel Wire Product Factories: For processing stainless steel wires, aluminum wires, etc., in making wire meshes or fences, it meets length and straightness requirements for diverse products.

3. Small Processing Shops: For small shops with flexible processing needs, YG Machinery’s machine is easy to operate and stable, handling small-batch, multi-specification tasks, improving service and efficiency.

Choose Rebar Straightener for Worry-Free Production

YG Machinery’s steel bar straightening machine, with precise performance, stable operation, and wide application, supports steel bar processing. It passes market tests. Choosing it means an efficient solution. Contact us for details or purchases. We also sell thread rolling machines, bending machines, pipe bending machines, etc.【WhatsApp/WeChat/Phone】+86 13837122632