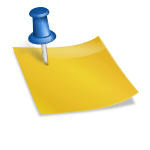

The hydraulic diamond cutting wire saw uses hydraulic power to drive a diamond-embedded rope, enabling clean and efficient cutting of reinforced concrete and natural stone. Its vibration-free and low-noise features make it especially suitable for sensitive environments where structural integrity must be preserved. In addition, YG Machinery also provides high-frequency wire saws, hydraulic wire saws, and electric wire saws. Feel free to contact us for more product details and exclusive quotations!【WhatsApp/WeChat/Phone】+86 13837122632

Parameters of Hydraulic Diamond Cutting Wire Saw

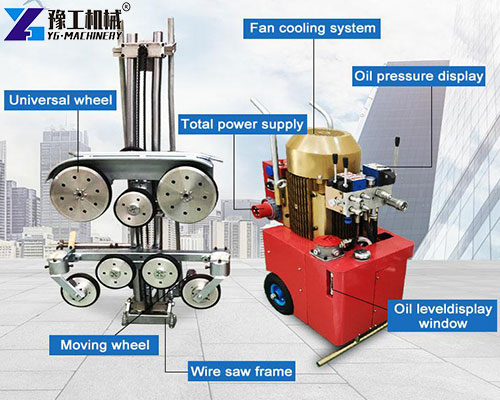

Wire saw frame parameters

| Item | Specification |

| Motor quantity | 2 pcs |

| Cutting speed | 5 m²/h |

| Max wire storage | 12 m |

| Wheels quantity | 7 pcs |

| Feeding method | automatic hydraulic |

| Weight | 110 kg |

| Dimension (LWH) | 10507002100 mm |

Hydraulic pump station parameters

| Item | Specification |

| Power | 25 kw |

| Working voltage | 380v, 50hz, 3phase |

| Motor cooling method | Air cooling |

| Working speed | 1300 r/min |

| Max pressure | 210 bar/21 Mpa |

| Oil flow rate | 3000 RPM |

| Weight | 118 kg |

| Dimension | 500 mm520 mm1100 mm |

| Hydraulic oil model | 46#/48# |

Working Principle of Diamond Cutting Wire Saw

- Hydraulic power start: The process begins with the hydraulic pump station generating oil pressure to drive the hydraulic motor. This motor converts hydraulic energy into rotational motion, ensuring smooth and controlled power output.

- Rope movement and guidance: The rotating motor drives the driving wheel, which in turn propels the diamond bead rope. Multiple guide wheels direct the rope along the predetermined cutting path, achieving high-speed rotation while minimizing material waste.

- Cutting action: When the rope moves at speeds up to 5 m²/h, the diamond beads grind through tough surfaces such as concrete or stone. The automatic hydraulic feeding system dynamically adjusts rope tension and speed, enabling precise cutting without manual intervention.

- Application flexibility: This setup allows the hydraulic diamond wire cutting saw to handle thick and large materials, making it especially suitable for demanding projects such as bridge demolition or underwater structures requiring high precision.

4 Advantages of Using Hydraulic Diamond Wire Cutting Saw

- High efficiency and speed: With a cutting speed of up to 5 m²/h, project timelines are significantly reduced. The hydraulic system provides continuous power, completing tasks faster than mechanical saws.

- Precision and safety: Guided rope movement ensures clean cutting with minimal vibration, protecting surrounding structures. This is especially critical in renovation projects or sensitive environments where damage risk must be minimized.

- Cross-material versatility: Although commonly used for concrete, this saw also performs excellently as a wire saw for stone, handling granite, marble, and other natural stones with ease. Its adaptability makes it a valuable asset in quarries or heritage restoration.

- Durability and low maintenance: Components of the diamond wire saw are designed for long-lasting use, supported by features such as air cooling and robust construction. This results in lower long-term operational costs.

Common Application Areas

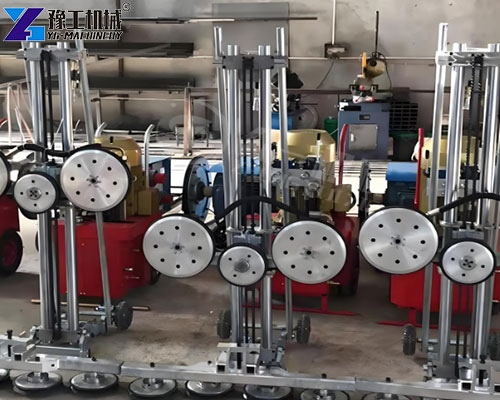

- Large reinforced concrete demolition: Widely used in static cutting of bridges, piers, dock platforms, and load-bearing walls, ensuring the original structure remains undamaged by vibration.

- Stone quarrying and processing: As an efficient cutting tool, it is applied for block shaping in quarries and slab cutting in processing plants.

- Special projects and emergency rescue: Suitable for nuclear power plant renovation, rapid rescue cutting at disaster sites (such as post-earthquake), and other complex projects requiring precise control of cutting shape and dimensions.

Factors Affecting Diamond Wire Saw Price

- Diamond quality and concentration: The quality, grit size, and concentration of the diamond beads on the rope are primary cost drivers. Higher quality diamonds offer longer life and faster cutting speed but increase costs.

- Equipment specifications and brand: As shown in the parameters, factors such as hydraulic pump power, automation level, and brand reputation directly influence the overall price of the hydraulic diamond wire cutting saw system.

- Rope length and diameter: Depending on cutting thickness and project requirements, rope length and diameter vary, which directly impacts diamond wire saw price. Longer or specially designed ropes naturally cost more.

Suitable Users and Purchasing Advice

- Construction contractors: Shorten project timelines and reduce labor costs.

- Infrastructure units: Ensure construction safety in bridge and tunnel renovation.

- Equipment rental companies: With growing market demand, investing in hydraulic diamond cutting wire saw enhances competitiveness.

When purchasing, besides focusing on diamond wire saw price, buyers should also evaluate power, cutting speed, and maintenance services for a comprehensive decision.

In summary, the hydraulic diamond wire cutting saw represents an efficient, precise, and versatile cutting technology. As technology continues to evolve, it will play an increasingly critical role in shaping the built environment. Furthermore, YG Machinery also offers splitters, rock saws, and double-cylinder hydraulic shears. Contact us today for exclusive discounts!【WhatsApp/WeChat/Phone】+86 13837122632