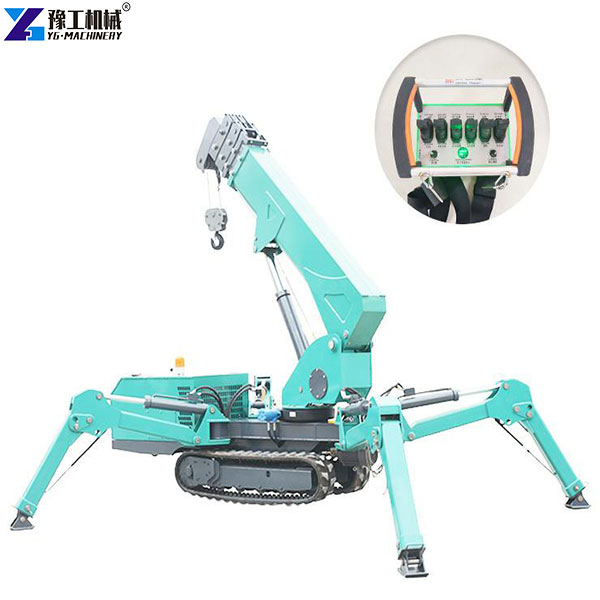

In today’s increasingly competitive global logistics industry, efficient and energy-saving material handling equipment has become the key for enterprises to enhance competitiveness. This article shares a typical case of a high-performance powered stacker successfully entering the U.S. market, showing how it helped a large logistics center in Texas solve practical operational challenges. In addition, YG Machinery also offers hot-selling equipment such as lifting platforms, boom lifts, scaffolding, and forklifts. Feel free to contact us anytime for an exclusive quotation! 【WhatsApp/WeChat/Phone】+86 13837122632

Hot-Selling Powered Stacker Parameter Table

Below are the detailed technical specifications of the self loading stacker used in this case:

| Parameter Category | Specific Parameter | Parameter Category | Specific Parameter |

| Product Model | YG-15 (Stand-on) | Lowered Height | 90mm |

| Rated Load | 1500kg | Overall Length | 2140mm |

| Load Center | 500mm | Fork Size | 60×170×1100mm |

| Front Overhang | 960mm | Body Width | 850mm |

| Wheelbase | 1555mm | Fork Outer Width | 690mm |

| Self Weight (with battery) | 700 – 1100kg | Ground Clearance at Wheelbase Center | 40mm |

| Wheels | Polyurethane | Turning Radius | 1600mm |

| Front Wheel Size | 250×80mm | Drive Type | Electric (Battery) |

| Rear Wheel Size | 80×70mm | Travel Speed (Loaded/Unloaded) | 4/5.6km/h |

| Front Wheel Track | 886mm | Lifting Speed (Loaded/Unloaded) | 0.08/0.1m/s |

| Rear Wheel Track | 525mm | Lowering Speed (Loaded/Unloaded) | 0.12/0.09m/s |

| Lifting Height | 1600 – 3500mm | Gradeability | 6/10% |

| Lifting Motor Power | 2.2kW | Service Brake | Electromagnetic |

| Battery 24V | 120/130Ah | Drive Motor Power | 1.5kW |

Customer Background and Challenges

This medium-sized logistics center in Texas specializes in providing warehousing and distribution services for e-commerce companies. With rapidly growing business volume, they faced the following challenges:

- The original manual handling equipment was inefficient, often causing order delays and slow turnover, making it difficult to keep up with the sharp rise in customer demand during seasonal peaks.

- Labor costs were continuously rising, with more workers required for extended shifts, increasing the overall operational budget and reducing profit margins for the logistics center over time.

- Warehouse space utilization was not high, as traditional handling equipment could not easily reach higher racks, leading to wasted vertical storage capacity and limited room for expanding inventory.

They urgently needed to find a suitable powered stacker to address these problems.

Solution and Equipment Selection – YG-15 Full Electric Stacker

After extensive comparison, the logistics center finally chose our YG-15 full electric stacker. This model has the following outstanding features: the fully electric drive system ensures zero emissions, meeting California’s strict environmental standards; its compact design is suitable for narrow aisle operations; and its high load capacity meets most warehousing demands.

Particularly noteworthy is the electric lift stacker intelligent control system, which greatly simplifies operations. Operators only need brief training to use it proficiently, significantly reducing labor costs.

Implementation Results of YG Full Electric Stacker

After putting the full electric stacker into use, the logistics center saw significant improvements in operational efficiency:

- Order processing speed increased by 40%.

- Labor costs decreased by 30%.

- Warehouse space utilization improved by 25%.

The customer especially praised the reliability of the full electric stacker: “These machines run for more than 10 hours a day with almost no breakdowns.”

Powered Stacker Purchase Advice and After-Sales Support

If you are considering purchasing suitable material handling equipment for your business, here are some practical suggestions:

- First, clearly define your needs, including daily workload, warehouse layout, and budget.

- When choosing a specific model, focus on key factors: load capacity for daily requirements, lifting height for rack specifications, and battery endurance for work shifts.

Our electric lift stacker series is equipped with high-performance batteries that support up to 8 hours of continuous operation, ensuring uninterrupted full-day work.

During procurement, we recommend that customers prioritize equipment safety features and after-sales support. All powered stacker models comply with U.S. safety standards and come with multiple safety protection systems. Meanwhile, we provide a comprehensive after-sales service system to ensure your equipment always operates at its best.

Feel free to contact us anytime! 【WhatsApp/WeChat/Phone】+86 13837122632

No responses yet